Screw-retained abutment protective caps shield dental implants from contamination, stress, and damage, ensuring seamless healing and long-term stability.

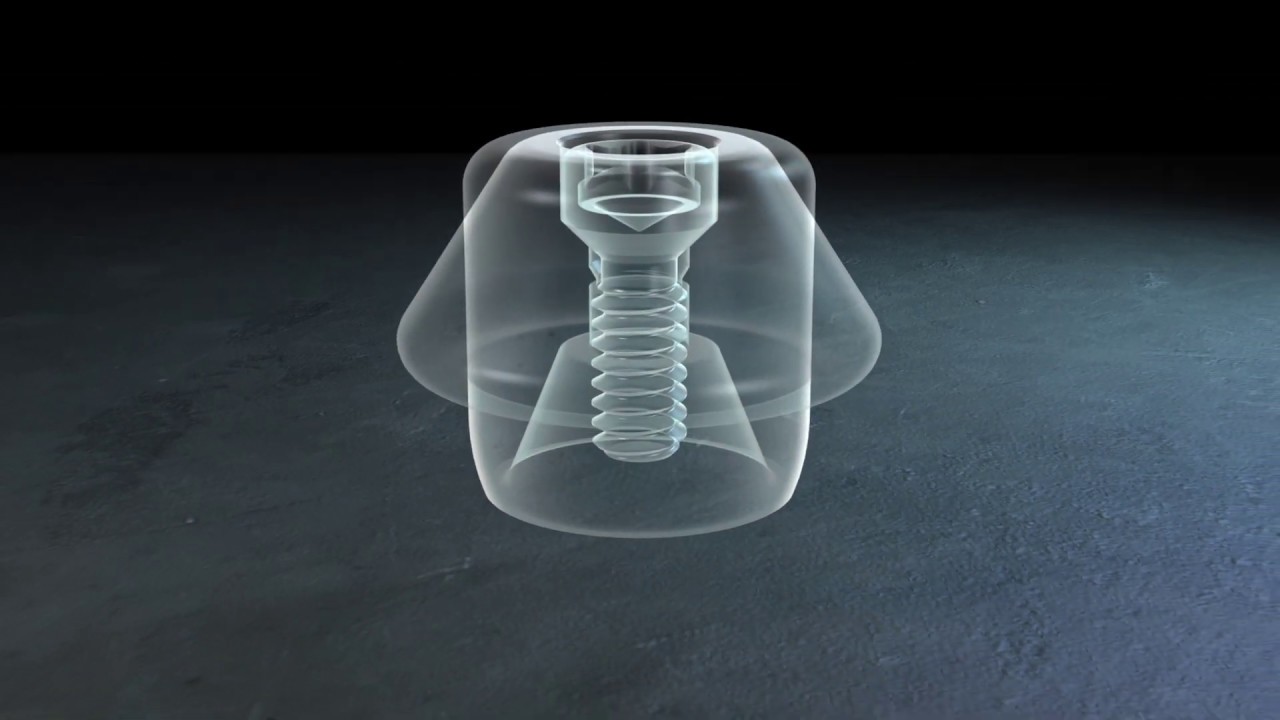

A screw-retained abutment protective cap is a crucial component in dental implant systems, serving to protect the screw-retained abutment during the healing phase and while the final restoration is being fabricated. It is designed to safeguard the abutment from contamination, external debris, and mechanical stresses that could compromise its fit, function, and overall success. The dental abutment protective cover fits securely over the abutment, ensuring it stays in place during the implant healing period while maintaining an optimal environment for osseointegration. By acting as a barrier, this component helps preserve the integrity of the dental system, ensuring a seamless transition to the final prosthetic.

Manners Technology is known for producing high-quality screw caps with meticulous attention to detail and precision. Our state-of-the-art manufacturing process ensures that every protective implant abutment protective cap fits perfectly and meets stringent medical industry standards.

One of the primary applications of the protective cap for screw-retained abutment is during the post-surgery healing period. After implant placement, the screw-retained abutment can be exposed to various environmental factors, including saliva, bacteria, and food particles. The abutment cap provides a barrier that prevents contaminants from entering the abutment connection, ensuring a clean environment conducive to proper healing and osseointegration.

In cases where a temporary restoration is necessary, the protection cap is also essential in preventing mechanical stress on the abutment. By covering the screw-retained abutment, the cap helps distribute forces evenly and protects the abutment from potential damage or dislodgement during the interim period. This ensures that the implant system remains intact and fully functional while awaiting the final prosthetic.

The biocompatible protective cap also plays a role in maintaining the stability of the implant system. By preventing foreign objects or debris from entering the implant site, it reduces the risk of complications such as infections, loosening of the abutment, or damage to the implant itself. The tight fit of the cover ensures that the abutment remains undisturbed during the healing phase, promoting better long-term stability and functionality.

In some cases, the caps for protecting abutment connection are used in conjunction with immediate implant placement. During the healing period, when the permanent restoration is not yet placed, these screw-retained implant abutment caps ensure that the implant and abutment are protected from potential damage, allowing for better aesthetic results once the permanent restoration is attached.

Manners Technology manufactures protective caps that are precision-engineered to fit a variety of implant systems. Our implant screw cover caps for abutment are designed to be durable and reliable, ensuring they meet the high standards expected by dental professionals for optimal patient care.

The manufacturing of screw-retained abutment caps requires precision and attention to detail, given the critical role these components play in securing dental implants. These caps must exhibit not only mechanical strength but also excellent biocompatibility, corrosion resistance, and precise fit. The production process involves several key stages, each requiring specialized techniques to achieve the desired product specifications.

The first step in the manufacturing process is selecting the right materials. Titanium is the most commonly used material due to its excellent strength-to-weight ratio, biocompatibility, and resistance to corrosion. For non-metal caps, medical-grade plastics such as PEEK or POM are used for their durability and ease of molding, as well as their excellent resistance to wear.

The core of manufacturing protection cap for abutment screw hole involves computer numerical control machining, particularly turning and milling. The precise geometry required to match implant systems demands multi-axis machining capabilities. The bulk of the material is removed to form the cylindrical or conical shape of the cap. During this process, the exact diameter and height are carefully controlled.

Once the basic shape is established, milling operations are performed to refine critical details such as internal threads, anti-rotational features, and the engagement point for the abutment screw. High-precision multi-axis machines with capabilities to perform multiple cuts in one setup ensure that features like hexagonal or conical interfaces are precisely formed. These interfaces must fit perfectly with both the implant and the abutment screw, ensuring stability and preventing rotation under load.

Internal threading is a crucial step in the process, as it provides the mechanism by which the abutment cap secures onto the implant. Thread dimensions, including the pitch, depth, and diameter, must be executed with micron-level precision. The CNC threading tools used for this purpose are calibrated to produce consistent, high-quality threads with minimal variation.

Manners Technology employ Sliding Headstock Type Automatic CNC Lathe - Citizen, which can complete all operations on one machine and come out the product at one time, which ensures high efficiency and reduces the possibility of error.

Screw-retained abutment protective caps are essential components in maintaining the integrity of dental implant systems during the healing process and temporary restoration phases. Their role in protecting the abutment from external debris, contamination, and mechanical stress is vital for ensuring the success of the implant procedure. Through advanced manufacturing technologies, rigorous quality control, and precise testing, Manners Technology ensures the production of reliable, high-quality protective caps that contribute to better patient outcomes and the longevity of dental implants.