High-quality titanium bases for dental implants ensure strength, biocompatibility, and durability. Explore Manners Technology's customizable solutions.

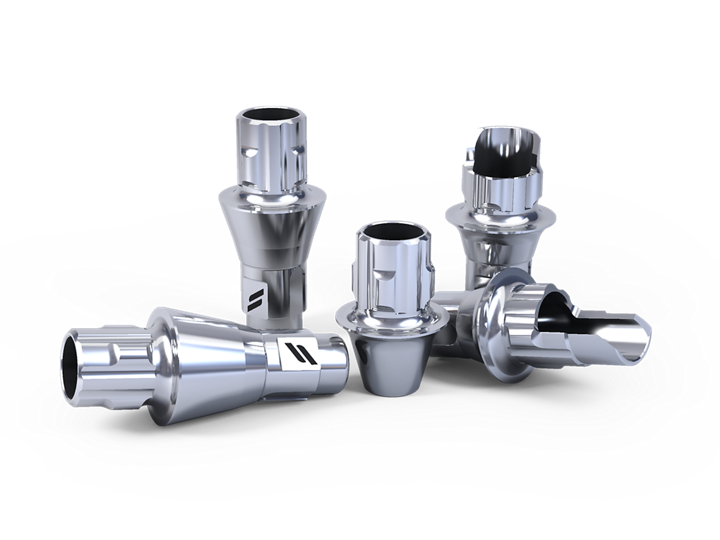

Titanium bases are an essential component in dental implant systems, serving as the foundation for various prosthetic restorations. Made from high-quality titanium, these bases are known for their strength, durability, and biocompatibility, making them ideal for use in dental implants that require long-lasting performance. Manners Technology provides both temporary and permanent dental implant Titanium bases, ensuring consistent quality for both types of applications. Our manufacturing process guarantees that the Titanium implant bases are durable and reliable throughout the entire treatment process.

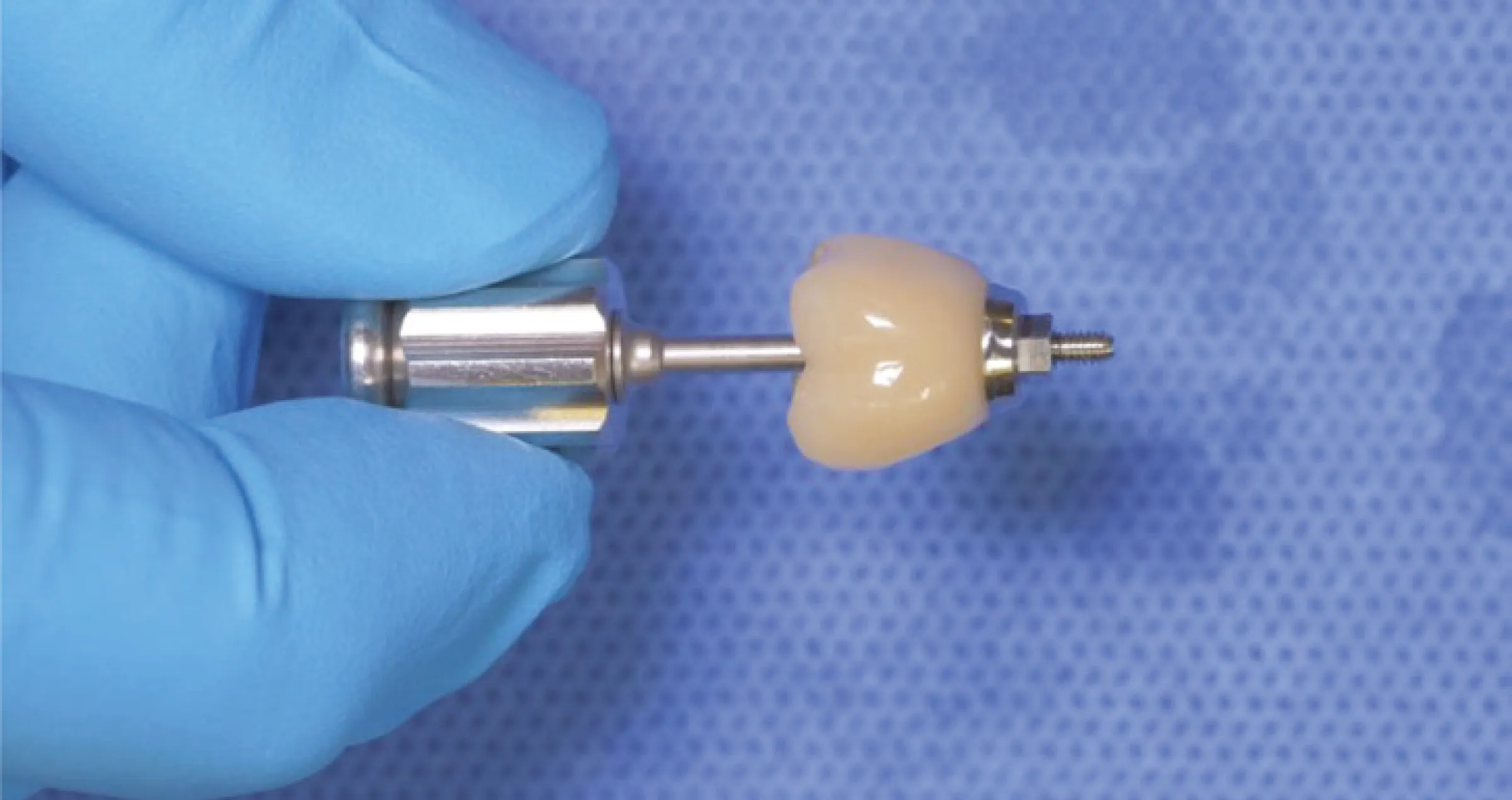

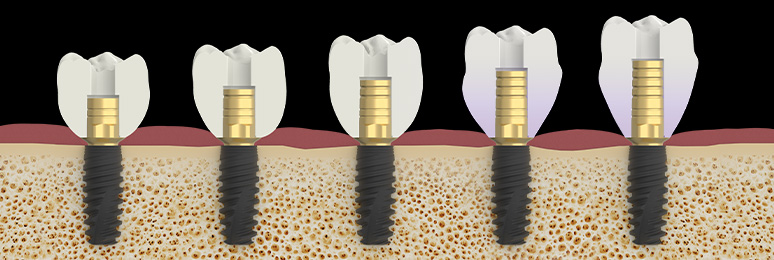

Titanium bases are commonly used as the underlying support for a variety of dental restorations, including crowns, bridges, and dentures. They provide a secure and stable platform that ensures the prosthetic components stay firmly in place. This is particularly important in cases where high occlusal forces are at play, such as in molar restorations. Titanium’s high strength and biocompatibility make it an ideal material for these applications, allowing for long-term functionality.

Titanium bases for implant restoration are versatile and can be customized to fit various implant systems, offering flexibility in treatment options. Depending on the patient's needs, implant Titanium bases can be designed with different interface geometries, including conical, hexagonal, or multi-hex designs. This customization ensures that the titanium base integrates seamlessly with the implant, providing a stable connection for the prosthetic component.

Titanium bases can be used both as temporary solutions during the healing phase of implant surgery and as permanent components in the final restoration. During the healing phase, they allow for the creation of provisional restorations that help maintain the integrity of the gum tissue. For permanent restorations, biocompatible Titanium implant bases provide a solid foundation for attaching crowns or bridges that will function over the long term.

While titanium bases are primarily functional, they also contribute to the aesthetic outcomes of dental restorations. In cases where a more aesthetic solution is needed, titanium bases can be designed with an emergence profile that enhances soft tissue integration and improves the appearance of the final restoration. This is particularly important for anterior restorations, where the esthetics of the gum line are critical.

At Manners Technology, we work closely with dental professionals to ensure that customizable Titanium base for implantss are customized to meet both functional and aesthetic needs. Our advanced manufacturing capabilities allow us to produce bases that promote excellent tissue integration and aesthetic results.

The first step in manufacturing titanium bases is selecting the appropriate grade of titanium. Titanium Grade 5 (Ti-6Al-4V ELI) is the most commonly used material for these bases due to its excellent strength-to-weight ratio, corrosion resistance, and ability to bond with bone. The material undergoes strict quality control to ensure its biocompatibility and mechanical properties meet industry standards.

The heart of titanium base manufacturing lies in precision machining. At Manners Technology, we utilize advanced multi-axis lathes to shape the Titanium dental base plate with micron-level accuracy. Their manufacturing process involves advanced automated production systems, which increase both precision and efficiency. Fully automated feeding systems are used in the manufacturing process, ensuring a consistent and uninterrupted production flow. This allows for high-volume production without compromising the quality of each individual base. The automation of the process also reduces human error, ensuring that each precision Titanium base produced adheres to the exacting standards required for successful clinical outcomes.

These machines allow for the creation of highly intricate and complex geometries that are essential for ensuring a perfect fit with the implant system. The bases are machined to the exact specifications required, including the interface geometry and screw holes for secure fixation.

Our Swiss type 5-axis longitudinal lathes provide unmatched precision in turning and milling operations, allowing us to produce dental Titanium bases that meet stringent tolerances and quality standards. With these advanced technologies, we can create custom bases that meet the exact requirements of each clinical case.

After the base is shaped, surface treatments are applied to enhance its performance and longevity. For titanium, common treatments include anodization and sandblasting, which improve the base’s osseointegration properties and reduce bacterial adhesion. These treatments help the titanium base bond more effectively with the bone and promote long-term stability.

Once the titanium base has been manufactured, it undergoes rigorous quality control to ensure it meets the required specifications. Coordinate measuring machines (CMM) are used to verify the precision of the dimensions and the alignment of the internal connections. Fit testing is also conducted to ensure compatibility with the implant system and to verify that the base for implant prosthetics will provide the necessary stability and retention for the prosthetic components. Our commitment to precision ensures that every base we produce is ready for seamless integration into dental implant systems.

Manners Technology employs cutting-edge automated manufacturing systems that enable us to produce high-quality titanium bases at scale while maintaining consistent precision and reliability. These systems ensure that our clients receive the highest-quality titanium bases, delivered on time and meeting all necessary specifications for clinical success.