Find the right meniscal repair needle by focusing on shape, material, and surgical technique—practical insights for sports medicine teams and device buyers.

Meniscal injuries are among the most common orthopedic problems, especially among athletes and active individuals. Proper surgical repair requires not only skill but also precise tools—most notably, meniscal repair needles. These specialized devices play a vital role in minimally invasive techniques that aim to preserve joint function and reduce long-term complications. Choosing the right needle for meniscus repair comes down to a few key things—design, structure, material, and clinical adaptability.

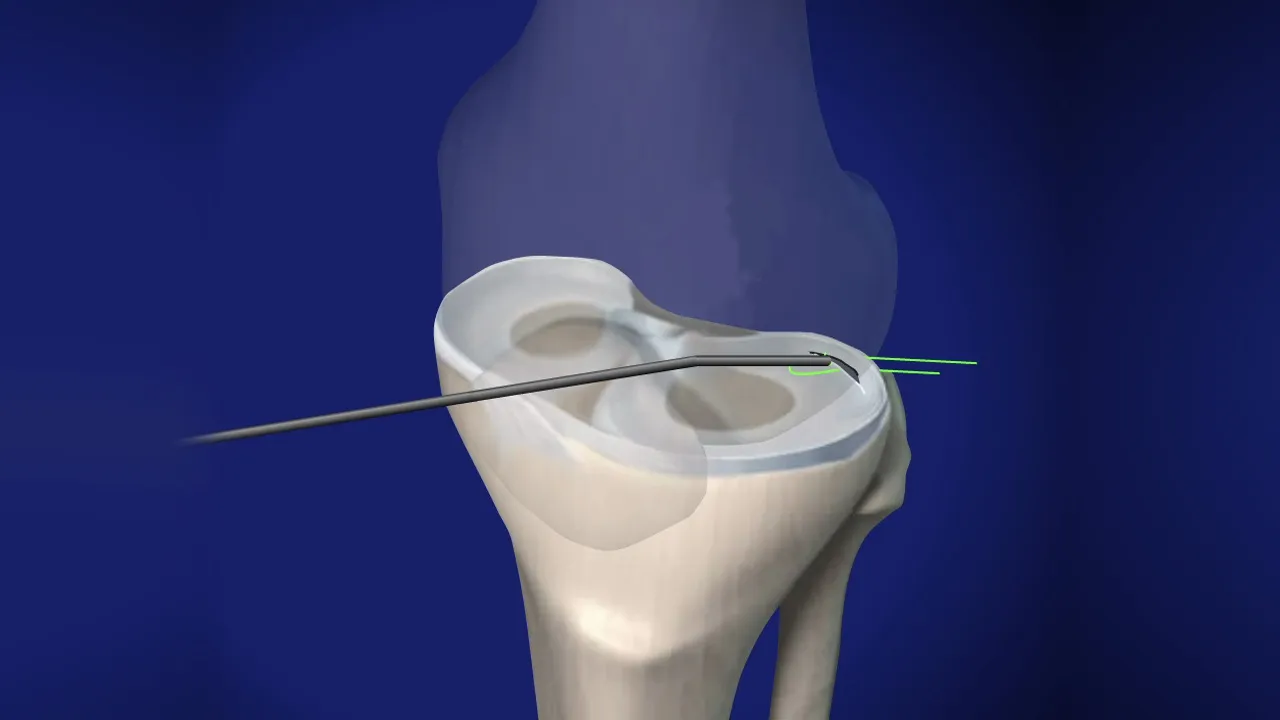

A meniscal repair needle is a fine, often curved or angled surgical needle used to pass sutures through the torn meniscal tissue inside the knee joint. It is a core component in inside-out, outside-in, and all-inside meniscal repair systems.

These needles must navigate tight joint spaces, maintain suture integrity, and ensure strong fixation to promote healing.

Curved vs. Straight

Curved meniscal needles allow for greater maneuverability around posterior horn tears or tight joint areas.

Straight needles provide more force during insertion and are often used in outside-in techniques.

Tip Design

Needles may feature sharp or blunt tips depending on whether they are designed to pierce tough cartilage or pass through soft tissue. The choice affects both safety and handling.

Most meniscal repair needles are manufactured using medical-grade stainless steel or high-performance alloys. The material impacts:

Rigidity: A stiffer needle allows for greater control during insertion.

Flexibility: Some procedures demand a needle that bends without breaking.

Corrosion Resistance: Especially important in reusable systems.

Some manufacturers also offer disposable meniscal repair needles, ideal for sterile, single-use environments.

Different surgical setups require specific needle compatibility:

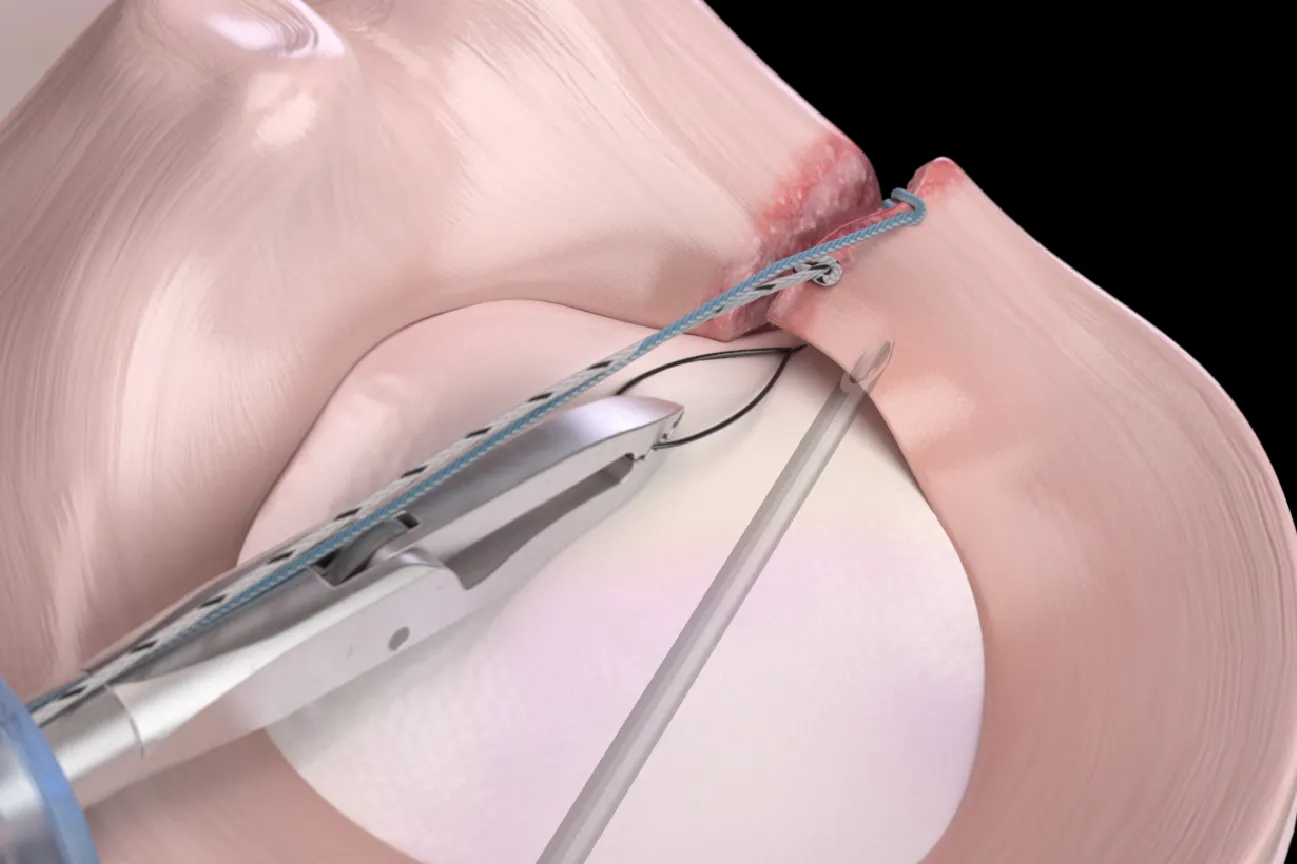

All-inside systems: Often use preloaded, integrated devices with specialized short needles.

Inside-out repairs: Require longer needles that can pass sutures through the joint capsule.

Outside-in techniques: Use cannulas and finer needle gauges for anterior tears.

Selecting a needle that fits seamlessly with your surgical system ensures procedural efficiency.

Different tear types—longitudinal, radial, or complex—demand different tools:

Posterior horn tears: Prefer longer, curved needles with flexible shafts.

Mid-body tears: Often accessible with straight or semi-curved designs.

Complex tears: Require adaptable needle and suture systems to achieve strong fixation.

Athletes and younger patients benefit from meniscal-preserving techniques, making needle precision more critical. In contrast, older patients with degenerative tears may require less aggressive approaches.

A high-quality meniscus repair needle should:

Fit well in the surgical handle or delivery device

Provide tactile feedback during penetration

Minimize wrist strain during arthroscopy

Surgeon fatigue or misalignment during insertion can compromise suture placement.

Needles with dull or overly sharp tips may damage cartilage or surrounding soft tissues. A properly designed needle optimizes control without sacrificing penetration efficiency.

Ensure the needle accommodates the intended suture material (e.g., 2-0 or 0 absorbable sutures). Some are preloaded; others require manual threading.

If you're a medical device company or hospital, consider OEM meniscal needle customization:

Tip geometry

Shaft length

Surface treatment

Handle compatibility

OEM options can reduce cost while meeting precise clinical requirements.

Criteria | Recommendation |

Needle Shape | Curved for posterior; straight for anterior |

Material | Stainless steel or high-performance alloy |

Technique Compatibility | All-inside, inside-out, or outside-in |

Suture Type | Check suture diameter and compatibility |

Sterility | Choose between reusable and disposable |

OEM Potential | Consider bulk customization for cost savings |

Selecting the right meniscal repair needle is crucial for successful sports medicine outcomes. Engineers and procurement professionals must weighneedle design, performance, and system compatibility to meet the growing demand for arthroscopic meniscal preservation.

Whether your priority is reduced cartilage trauma, strong suture placement, or system adaptability, the right needle design can directly impact healing success and patient recovery.