Explore how endoscopic biopsy needles, trocar needles, laparoscopic cannulas, arthroscopy shaver blades, meniscal repair needles, and laser cut hypotubes are shaping the future of minimally invasive surgery with precision engineering.

Minimally invasive surgery (MIS)has revolutionized patient care by reducing recovery times, lowering complication risks, and improving overall outcomes. Instead of large incisions, MIS relies on advanced instruments and visualization systems to navigate inside the human body with precision.

One of the biggest drivers behind this transformation is endoscopic device engineering. With improved flexibility, sharper visualization, and smaller profiles, today’s devices allow surgeons to perform complex procedures with unprecedented control.

Modern endoscopic tools enable:

Smaller incisions, minimizing blood loss.

Faster patient recovery compared to traditional open surgery.

High-definition visualization for accurate diagnostics.

Greater precision during tissue manipulation or resection.

At the core of many endoscopic devices are hypotubes—small-diameter, high-strength tubes engineered for flexibility and durability. By using advanced processes such as laser cut hypotube technology, manufacturers can design devices that bend in multiple directions while maintaining torque response and structural integrity.

These precision-engineered components support endoscopes, catheters, and surgical navigation systems, making them critical to MIS innovation.

Numerous tools made for tissue sampling, access, and navigation are used in endoscopic surgery. Every gadget helps to increase procedure efficiency and safety.

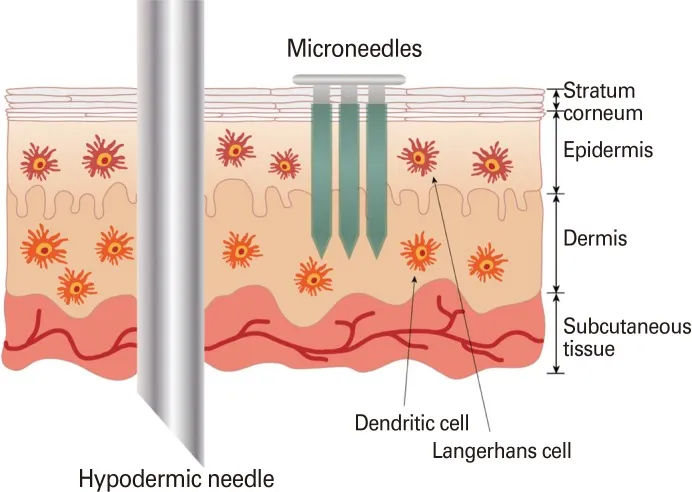

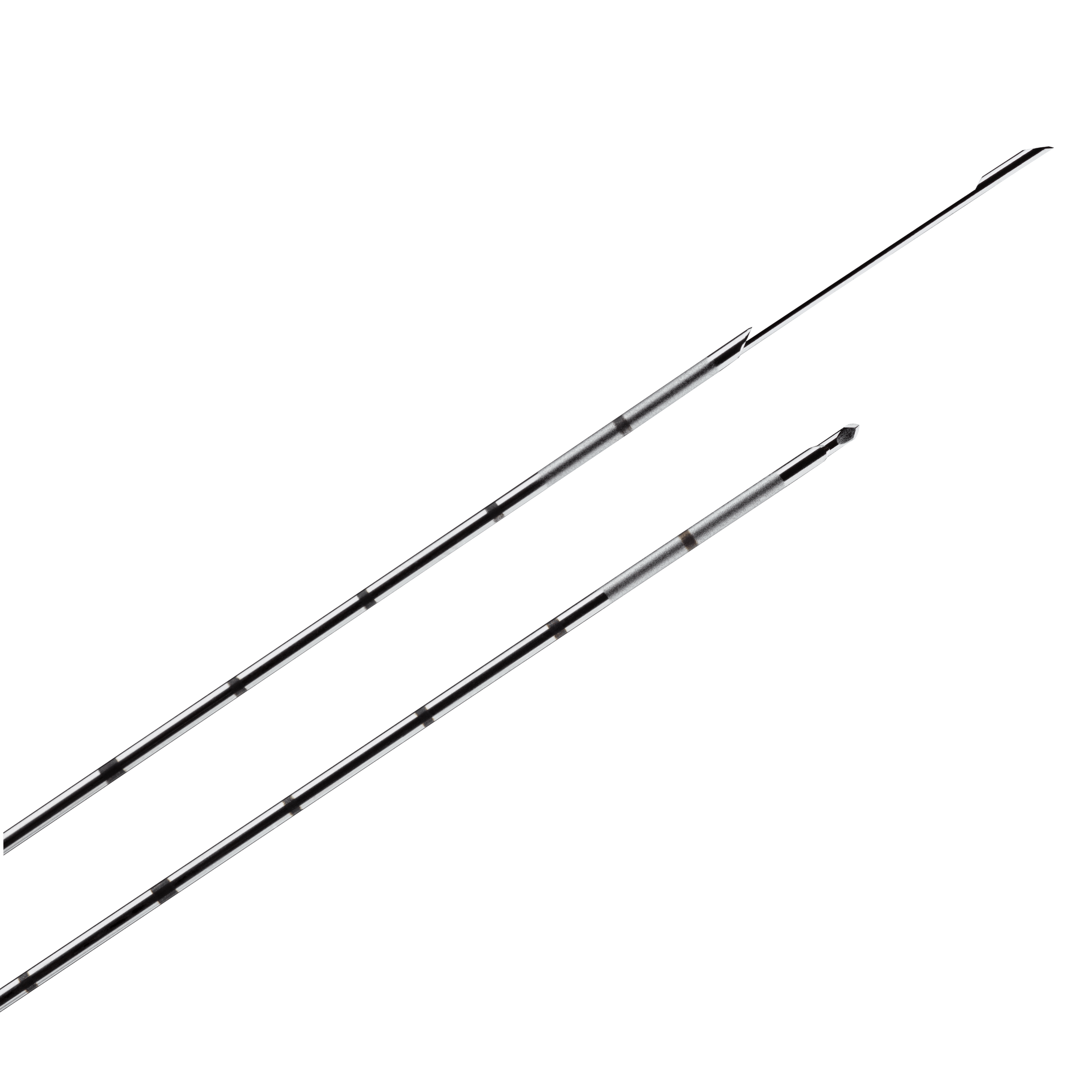

Biopsy needles are fundamental tools for tissue sampling. Endoscopic biopsy needles are available in different gauges (19G, 22G, 25G) depending on tissue density. They are used in gastrointestinal endoscopy, pulmonary diagnostics, and oncology for accurate histological evaluation.

High-precision 22G biopsy needles decreased sampling error rates by 18%, according to a recent clinical case at a tertiary hospital, guaranteeing more trustworthy pathology results.

Meanwhile, trocar needles are used to create safe entry points for laparoscopic surgery. With sharp tips and safety valves, trocar needles prevent unintended tissue damage while establishing pneumoperitoneum.

For abdominal access, surgeons rely on disposable entry systems.

Veress needles: Designed with spring-loaded tips for controlled peritoneal entry.

Laparoscopic cannula: Provides a stable port for instrument insertion, available in diameters from 5mm to 12mm.

Disposable trocars: Integrated with obturators to reduce trocar-site hernia risks.

Manufacturers often validate these products with ISO 13485 certification and perform 100% air-leak testing to ensure safety under pressure.

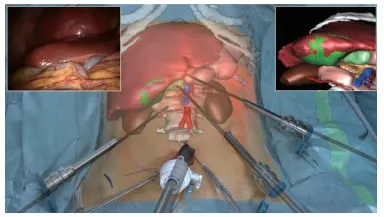

Surgeons can see every layer of tissue as it enters thanks to visual obturator systems, which combine access tubes and optical fibers. The chance of organ damage during abdominal access is reduced by this real-time feedback.、

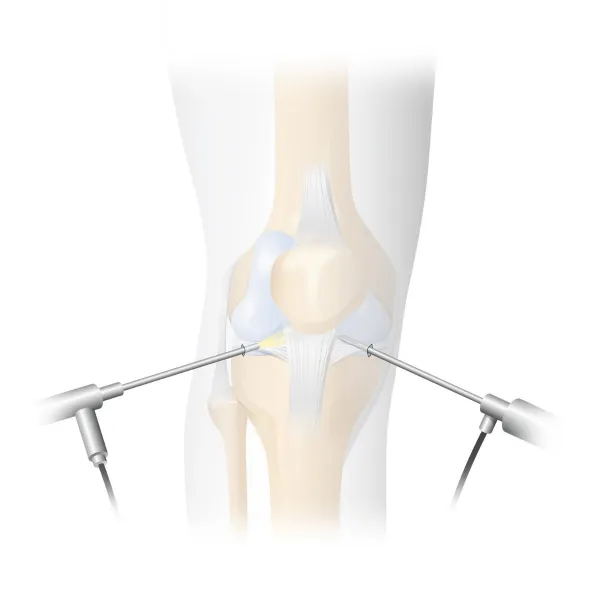

Orthopedic surgery has also benefited from MIS devices, particularly in joint procedures such as knee and shoulder arthroscopy.

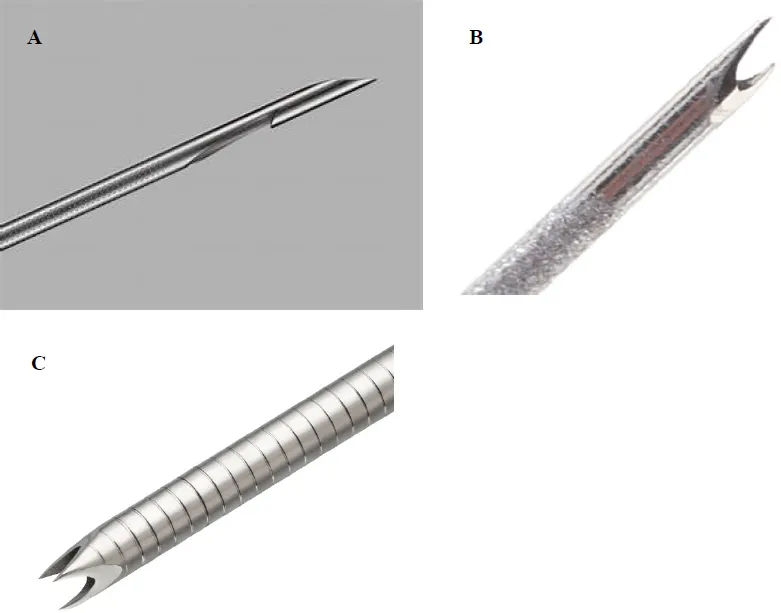

Arthroscopy shaver blades are engineered for precise removal of soft tissue, cartilage, and bone.

Tapered shaver blades: Ideal for accessing narrow joint spaces.

Sharp-toothed shaver blades: Provide aggressive resection capability for dense tissue.

Typical specifications:

Sizes: 2.9mm, 3.5mm, 4.5mm diameters.

Material: Hardened stainless steel with electropolished finish.

Testing: >200,000 rotations fatigue-tested for durability.

Knee injuries often require meniscus repair. Meniscal repair needles are designed for minimally invasive suturing within the joint space. Their ergonomic handles and smooth needle passage improve surgeon control.

When used in conjunction with arthroscopy tubes, these instruments enable accurate suture placement without requiring extensive incisions. According to clinical research, meniscus repair using contemporary MIS needles preserves more native tissue than open surgery.

Orthopedic shaver blades with hardened cutting edges are ideal for extensive resection. Surgeons can remove bone fragments and cartilage while keeping a clear surgical field thanks to blades with dual-window designs that maximize suction efficiency.

The future of MIS is robotic surgery, which allows for incredibly precise, tremor-free movements. Advanced device engineering is essential to the success of robotic systems.

Robotic surgical systems often feature miniaturized forceps jaws capable of rotating 360°. Made from high-strength alloys, these jaws provide stable gripping without tissue trauma. Surgeons can scale their hand movements into microscopic precision during delicate procedures such as urology or gynecology.

At the heart of many robotic systems are laser cut hypotubes, which enable flexible navigation while maintaining pushability. By creating specific cut patterns—such as helical or serpentine—the hypotube achieves multidirectional bending without kinking.

l Material options: Nitinol or stainless steel.

l Wall thickness: 0.1–0.3mm, customized per device.

l Testing: Fatigue life validated for >1 million cycles.

These hypotubes are essential in robotic-assisted endoscopy, electrophysiology, and neurovascular interventions.

From biopsy needles to arthroscopy shaver blades, and from laparoscopic cannulas to laser cut hypotubes, every device contributes to safer, more efficient minimally invasive surgery.

Precision-engineered tools will continue to be the foundation of innovation as surgical techniques progress toward robotic integration and AI support. The future of medicine will be shaped by producers with sophisticated production capabilities, stringent quality control procedures, and clinical validation.