Abutment-level scan bodies capture precise 3D data for prosthetic restorations, ensuring accurate and efficient dental workflows. Learn more about Manners Technology.

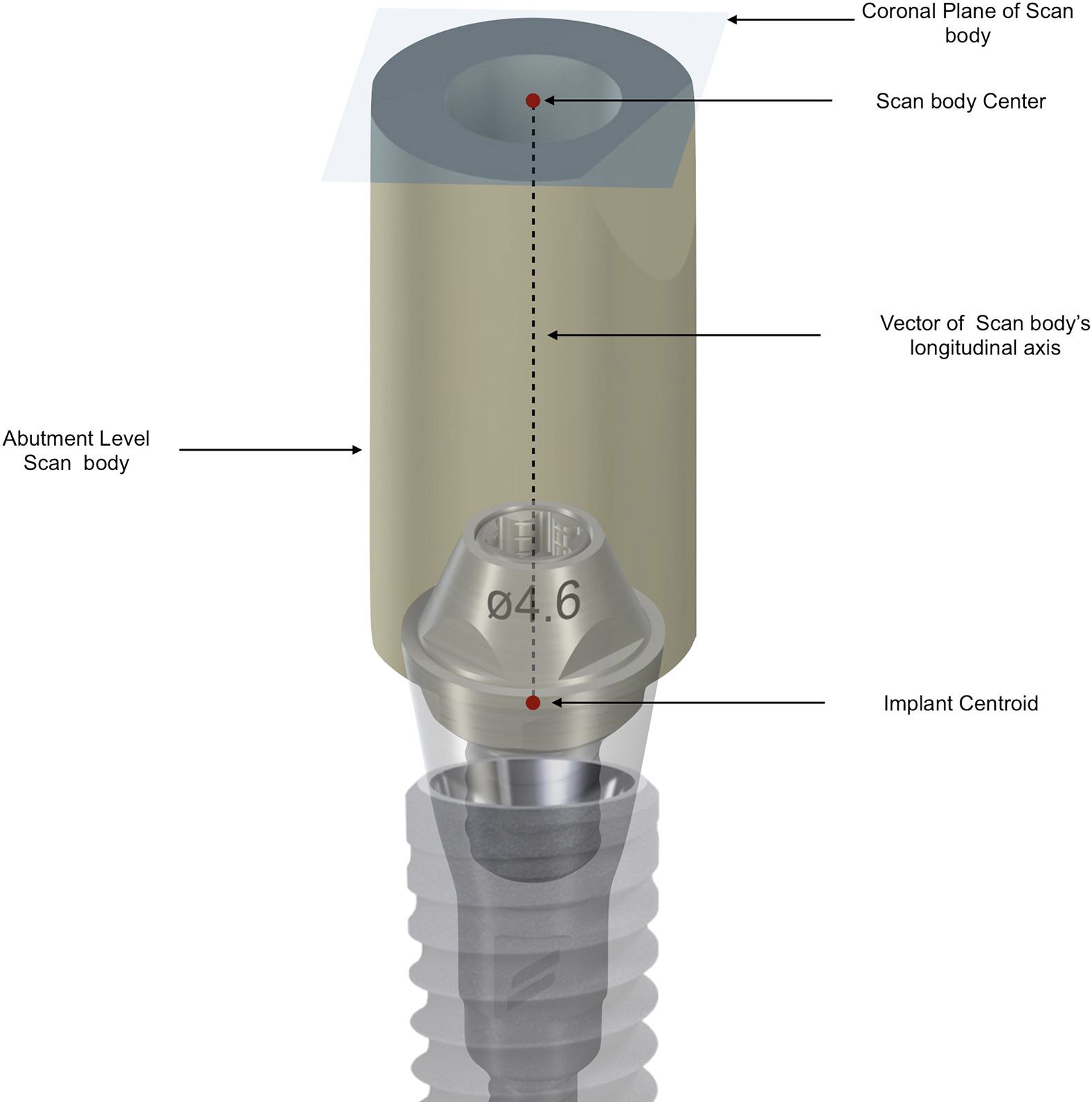

An abutment-level scan body is a key component in the digital workflow of modern implantology. It is designed to capture precise three-dimensional data from the abutment rather than directly from the implant fixture. Abutment scan bodies are placed on the abutment, allowing for accurate digital impressions that are essential for creating prosthetics such as crowns, bridges, and dentures. By replicating the exact position of the abutment, these dental scan bodies provide a reliable guide for prosthetic restoration, helping ensure a precise and functional fit. At Manners Technology, our state-of-the-art CNC machines and multi-axis capabilities ensure that every abutment level scan body meets the highest standards of accuracy and quality.

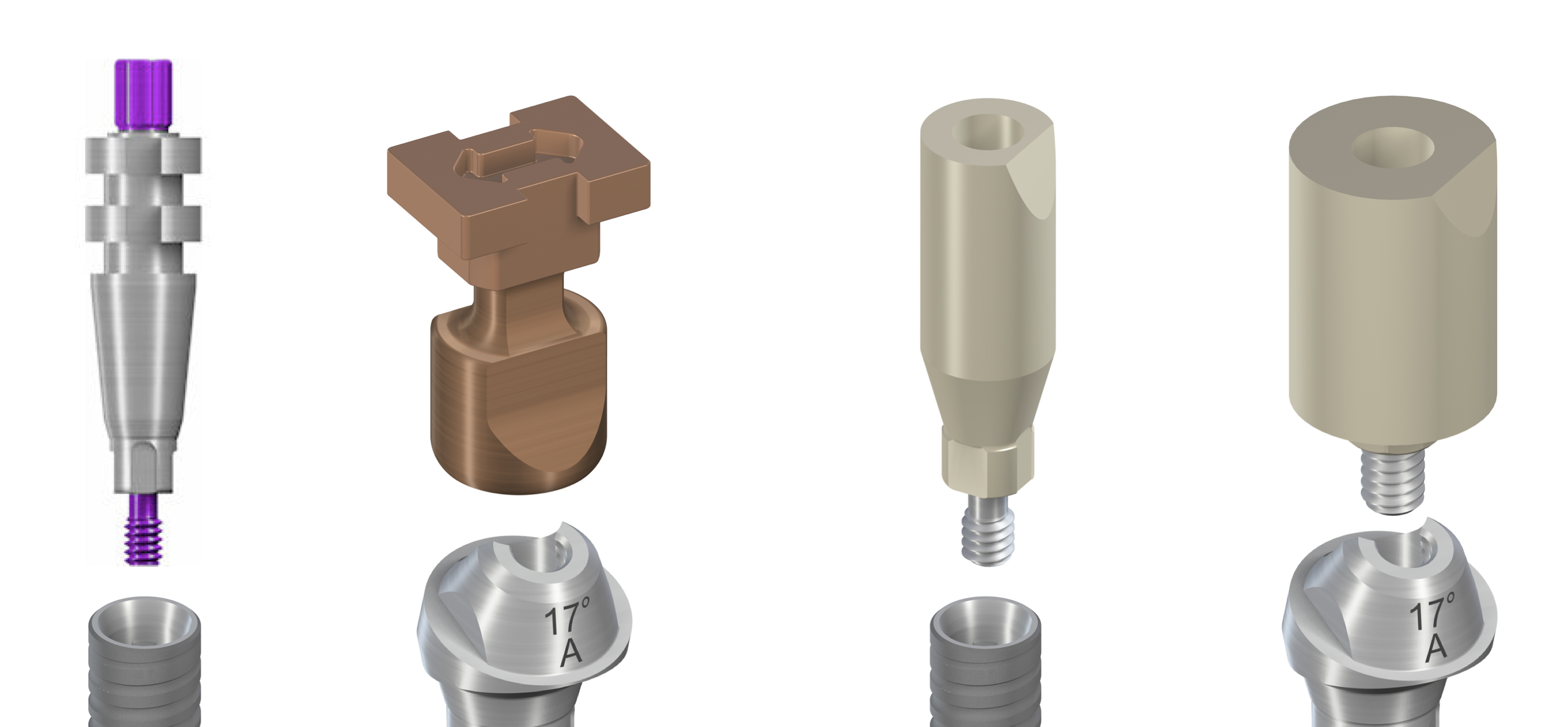

The abutment horizontal scan body for restorations serves several critical functions in the dental restoration process, providing benefits across various aspects of implantology. Below are some of the key applications:

In single-tooth restorations, the abutment horizontal scan body plays a vital role by capturing the exact position and orientation of the abutment. This data is then used to design and manufacture a custom crown that fits precisely on the abutment, ensuring a seamless aesthetic and functional result. The abutment scan body's compatibility with the abutment ensures a smooth digital workflow, eliminating the need for traditional physical impressions and reducing the risk of inaccuracies.

For multiple implant restorations, such as bridges or full-arch restorations, digital abutment horizontal scan bodies enable the precise alignment of the abutments in relation to one another. By capturing detailed information about each abutment's position, the scan body helps ensure that the multi-unit prosthetic fits securely and comfortably, achieving the necessary stability and functionality for long-term use. This is particularly important for patients requiring extensive dental work, where even minor discrepancies in abutment positioning could affect the outcome.

By providing an accurate digital representation of the abutment, abutment scan bodies streamline the overall restoration process. The use of digital scanning reduces the time spent on traditional impressions and the risk of errors associated with manual impression techniques. With these scan bodies, the dental laboratory can produce CAD/CAM-designed restorations faster, resulting in quicker turnaround times for patients and more efficient workflow for dental professionals.

Abutment level scan bodies facilitate the creation of prosthetics that fit seamlessly with the patient's natural dentition and gum line. By capturing the gingival contours and abutment position with high precision, the scan body helps ensure that the final restoration integrates smoothly with the surrounding tissue. This not only improves the appearance of the restoration but also enhances the patient's comfort and confidence.

At Manners Technology, we specialize in manufacturing high-quality customized abutment horizontal scan bodies designed to meet the most stringent standards. Our advanced manufacturing capabilities allow us to produce scan bodies that provide exceptional accuracy, compatibility, and ease of use, ensuring reliable results for dental professionals.

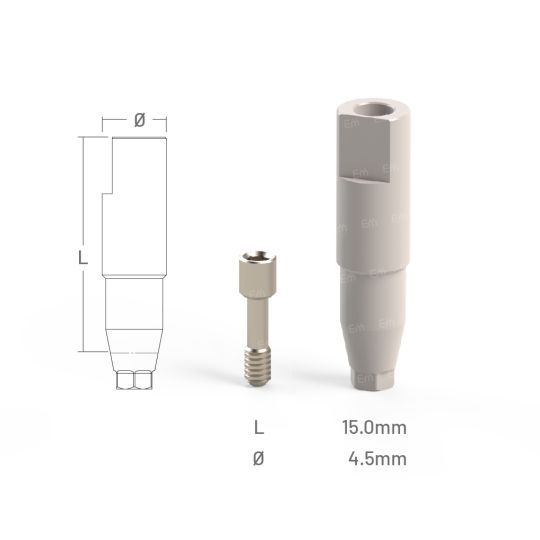

The manufacturing of abutment-level scan bodies involves several precise steps to ensure optimal fit, durability, and performance. Firstly, the materials selected must offer high durability and biocompatibility, as well as the ability to withstand the forces of the scanning process and the long-term use of the prosthetic. Horizontal scan bodies for implant abutment are often made from stronger, more rigid materials such as titanium or zirconia, as they must withstand the higher forces generated during the initial fitting and scanning process. The material needs to ensure long-term stability and precision, as the implant fixture is a more permanent part of the patient's anatomy.

The next step involves high-precision CNC machining to shape the scan body to the required specifications. At Manners Technology, we rely on advanced Citizen Cincom R04VI Swiss-type sliding headstock lathes and Swiss 5-axis lathes for the machining of these components. These machines are designed to handle the intricate and complex geometries often required for scanning bodies, offering unparalleled precision and versatility. This level of precision is critical for the compatibility of the implant with the scanning body, which must ensure a perfect fit with the implant fixture for accurate scanning. Our state-of-art lathes in these applications allows for the simultaneous machining of complex angles and geometric features without the need for multiple setups, which reduces machining errors and enhances production efficiency.

For abutment scanning bodies, these must not only fit the implant but also have to accommodate a prosthetic restoration. The high-precision longitudinal lathes are used to accurately machine features like the internal threads or grooves that allow the abutment and scanning body to lock securely together. Furthermore, the fine surface finishes required for these scanning bodies are achieved through precision machining, with all dimensions and surface textures meeting stringent specifications to maintain the integrity of the final restoration.

Manners Technology’s high-precision machines excel at maintaining micron-level accuracy, ensuring that all the features of the scanning body align perfectly with the necessary components, whether the purpose is to provide a physical model for scanning or to directly contribute to the final prosthetic. At Manners Technology, we specialize in producing high-precision scan bodies that meet the exacting requirements of modern digital dentistry, ensuring the most accurate and reliable results for dental professionals and their patients.