Discover how Bio-Force Soft Anchors enhance orthopedic surgery with flexible, biocompatible design for superior bone repair and patient comfort. Explore their versatile applications.

The Bio-Force Soft Anchor is an orthopedic surgical instrument composed primarily of a metal anchor body and a main line made of ultra-high-molecular-weight polyethylene (UHMWPE). Its notable feature lies in its soft and flexible nature, making it particularly suitable for patients who require more comfort and biocompatibility. The role of this soft anchor point is to provide reliable bone repair and connection while reducing postoperative discomfort for patients. The Bio-Force Soft Anchor plays a crucial role in orthopedic repair and connection, offering physicians an innovative solution designed to facilitate a faster and more comfortable recovery process. As a specialized manufacturer of this product, Manners Technology is committed to providing high-quality medical instruments to meet the evolving needs of the medical industry for advanced and reliable solutions.

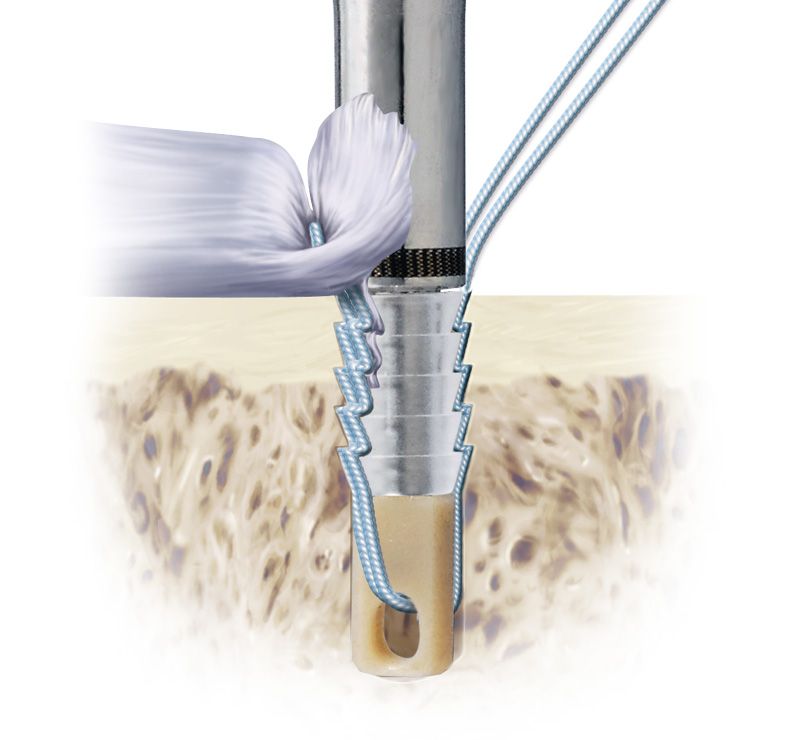

▲ Bio-Force Soft Anchor

The outstanding features of the Bio-Force Soft Anchor have led to its widespread application in various surgical scenarios, including Bankart lesion repairs, SLAP lesion repairs, and ligament repairs in the hand and other body parts, particularly excelling in areas like small joints, shoulders, and hips. In small joint surgeries, the flexible design of the Bio-Force Soft Anchor provides joints with more natural movement and greater flexibility, reducing the impact on surrounding soft tissues and creating more favorable conditions for patient recovery.

▲ Bio-Force Soft Anchor in surgical scenarios

In shoulder surgeries, especially in repairs for rotator cuff tears and shoulder joint stability, the superior performance of the Bio-Force Soft Anchor is fully realized. It offers reliable suture outcomes in rotator cuff repairs while providing optimal support for shoulder joint stability, resulting in improved treatment outcomes for patients. Additionally, for other shoulder issues such as glenoid labrum and biceps tendon repairs, the Bio-Force Soft Anchor plays a positive role.

In hip joint surgeries, the Bio-Force Soft Anchor demonstrates its superiority in acetabular labrum repairs. Its adjustability allows surgeons to fine-tune and customize solutions based on the specific conditions of each patient, providing a more personalized approach to hip joint surgeries and enhancing precision and success rates.

In summary, the widespread use of the Bio-Force Soft Anchor in various areas such as small joints, shoulders, and hips further highlights its unique position in the field of orthopedic implants. Manners Technology specializes in manufacturing these cutting-edge orthopedic products, offering healthcare professionals more choices and providing patients with better treatment experiences.

The Bio-Force Soft Anchor, representing a novel All-Soft Suture Anchor (ASA), aims to achieve optimal results in orthopedic surgery through precision manufacturing techniques. This innovative implant utilizes one or more sutures containing ultra-high-molecular-weight polyethylene (UHMWPE) and cleverly combines them with a metal anchor body, achieving a perfect blend of biocompatibility and robustness. This provides surgeons with a more flexible and adjustable option, ensuring the safety and success of the surgery.

▲ ultra-high-molecular-weight polyethylene combined with a metal anchor

The metal anchor body of the Bio-Force Soft Anchor is a crucial component that undergoes a highly precise manufacturing process. The CAD design is based on surgical requirements, determining the shape, size, and characteristics of the anchor body and main suture. High-quality metals, such as titanium alloy, are used to ensure the strength and corrosion resistance of the anchor body. During the processing, Manners Technology precisely shapes the metal anchor body and enhances its surface quality, ensuring smoothness and corrosion resistance for maximum safety and effectiveness during surgery. One unique aspect of the Bio-Force Soft Anchor’s design is that the sutures are woven through a sleeve or tape, distinguishing it from traditional anchors. In the precision manufacturing process, attention is given to the material and weaving method of the sleeve or tape to ensure the stability of the anchor’s formation and fixation.

▲ the surface of metal anchor body

The design of the metal anchor body allows the Bio-Force Soft Anchor to rapidly tighten the sleeve or tape against the overlying cortical bone when the main suture is pulled after insertion into the bone, forming a “ball” that acts as the anchor. This design allows the suture anchor to be placed in a smaller-diameter tunnel (1-3 millimeters), minimizing damage at the joint due to the softer anchor body. This unique and flexible mechanism requires CNC cutting through precision manufacturing techniques and instruments to ensure precise and reliable fixation during surgery. Additionally, considering the potential need for future revision surgery by surgeons after implant use, the manufacturing process needs to retain enough adjustability to accommodate different clinical situations.

▲ different types of metal anchor

Through precision manufacturing of the metal anchor body, a uniquely designed anchoring mechanism, and relentless exploration of biodegradability, Manners Technology has provided a solid foundation for the successful processing and application of the Bio-Force Soft Anchor, showcasing its innovative capabilities and high-quality control standards.