Find out why titanium is the preferred material for medical devices and surgical implants. Discover how its strength, corrosion resistance, and biocompatibility enhance patient outcomes and spur innovation in contemporary healthcare.

In addition to their durability, titanium products are chosen for their ability to promote healing, guarantee safety, and enhance quality of life.

The word "strength" frequently comes to mind when medical professionals and device designers think of titanium. However, titanium's benefits in surgical applications go well beyond its mechanical strength. One of the most valuable materials in contemporary medicine is its remarkable biocompatiblity, especially for surgical instruments and implants that need to interact with the human body in a safe, long-term manner. Understanding titanium's special properties and how to use them to improve treatment outcomes, reduce complications, and expedite the process from concept to clinical success is essential for medical design and manufacturing.

Titanium More Than a Tough Metal

The rise of titanium in medical applications is not solely due to its high strength and light weight, although it is renowned for these qualities. What has truly driven its use in surgery is its interaction with the human body. Today, titanium products are widely used across various fields, from orthopedic implants and spinal fixation systems to dental implants and surgical instruments.

Why? Titanium metal possesses the rare combination of biocompatibility and the ability to actively support the healing process. It not only does not damage tissues but also helps the body heal and integrate more effectively. Titanium metal continues to lead the way in the design of biocompatible medical devices for the following reasons:

1. Lightweight and durable

2. Highly corrosion-resistant

3. Promotes bone integration

4. MRI and imaging safe

5. Non-toxic and hypoallergenic

6. Long service life with minimal performance degradation

What Makes Titanium Highly Biocompatible

In addition to being robust and long-lasting, titanium interacts with the human body in a unique way that no other material can. Titanium has a special set of qualities that make it a great material for long-term surgery because of its biocompatibility. The following are the causes:

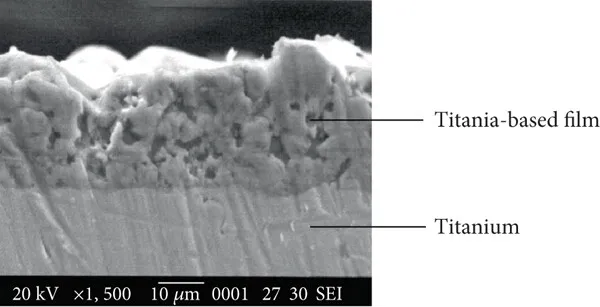

Oxidation Barrier in Nature

A thin layer of titanium dioxide is instantly formed when titanium and oxygen come into contact. This passive barrier shields the surrounding tissues from irritation and inflammation, inhibits ion release, and resists corrosion.

Inadequate Immune Reaction

The metal titanium is bioinert. Titanium integrates easily with the biological environment and causes little disturbance, in contrast to certain metals that can cause allergic or immunological reactions. This lowers the possibility of rejection and increases patient tolerance in a large population.

Encourages Cell Adhesion

Bone and soft tissue cells adhere to and proliferate on titanium surfaces, particularly those that are treated or textured. Tight biointegration is essential for implants because it stops migration, infection, and gradual loosening.

Cuts Down on Inflammation

Because titanium doesn't readily corrode or break down in the body, it doesn't introduce reactive substances that can lead to long-term inflammation. This speeds up recovery and lowers postoperative complications.

Extended Compatibility

Implants made of titanium are guaranteed to be safe and effective for many years due to its chemical stability and durability. For everything from orthopedic devices to dental implants, this dependability is essential.

Titanium performs exceptionally well in surgical applications because of a combination of biological advantages that make it particularly well-suited for long-term interaction with the human body, in addition to its strength and durability. These benefits serve as the cornerstone of its exceptional biocompatibility, which allows surgical instruments and implants to blend in perfectly, withstand biological deterioration, and continue to be safe for decades of use. Three of these advantages—its exceptional resistance to corrosion in demanding biological environments, its capacity to establish a strong bond with bone through osseointegration, and its hypoallergenic nature, which guarantees safety for a broad spectrum of patients—stand out as being especially important for medical design and patient outcomes.

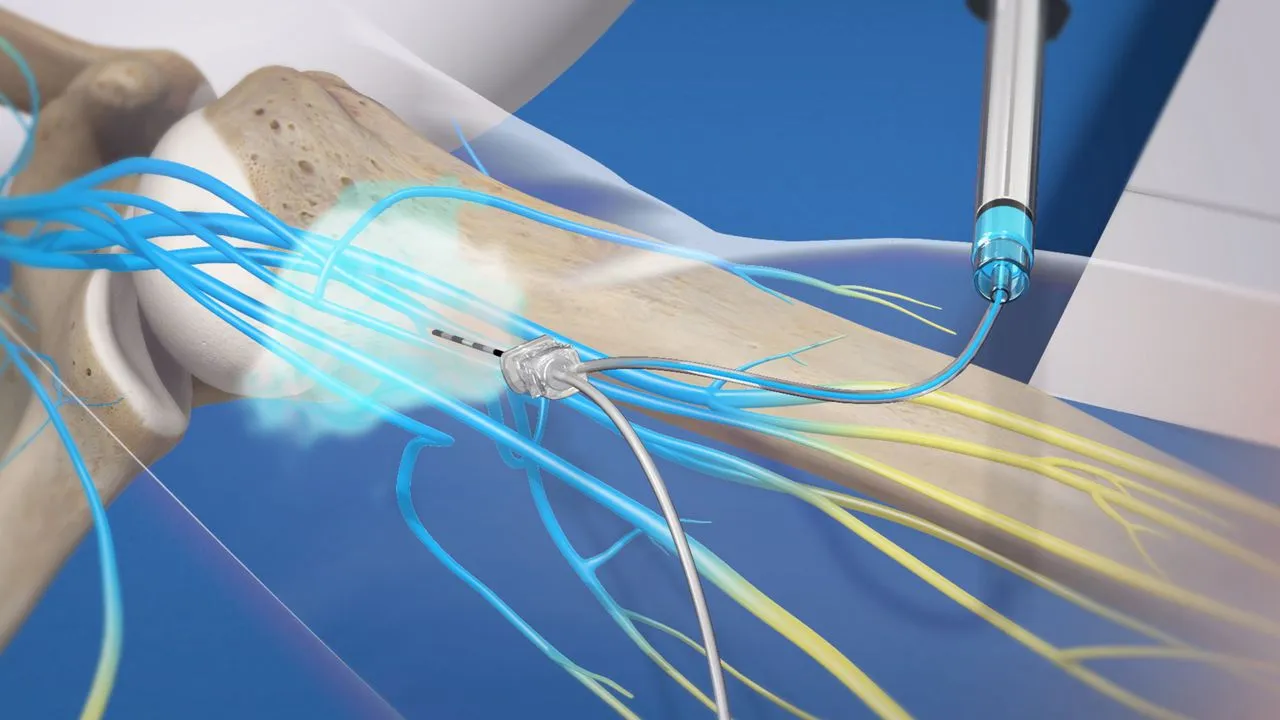

Osseointegration for Strong Bone Connection

The degree to which the implant blends in with the surrounding bone is a critical component of long-term surgical success in orthopedic and dental procedures. This is where titanium shines.

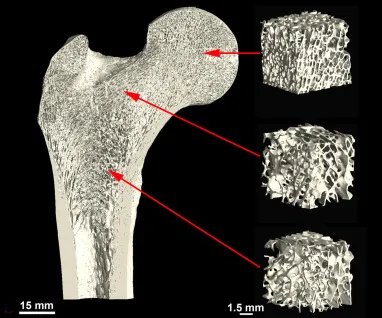

Osteointegration, the biological process by which bone tissue develops and adheres directly to the implant surface, is supported by titanium. This is not merely a passive exchange. Bone cells (osteoblasts) are actively encouraged to anchor and proliferate on titanium surfaces, particularly those that have been treated or textured. As the implant integrates with the skeletal system over time, stability, load transfer, and long-term viability are all enhanced.

Because of this characteristic, titanium is used extensively in dental fixtures, spinal implants, and joint replacements, as well as in precision tools such as bone marrow biopsy needles and soft tissue biopsy needles for diagnostic purposes.

Resistance to Corrosion in Biological Environments

Fluids, enzymes, and electrolytes abound in the surgical environment and internal anatomical structures, which are chemically aggressive. Under these circumstances, a lot of metals deteriorate over time, causing structural damage or the body to absorb toxic byproducts.

But titanium's oxide layer keeps it structurally sound. Even in places with high salinity or varying pH levels, like wound environments or close to bone, it is extremely resistant to corrosion from bodily fluids. Because of their durability, titanium products can continue to function dependably for many years to come.

Manufacturers of devices benefit from this corrosion resistance since it prolongs implant life and lowers the possibility of late complications, which are important factors for regulators and end users.

Hypoallergenic Properties for Long-Term Safety

The fact that titanium is hypoallergenic is yet another important benefit. Materials like nickel and cobalt-chromium alloys, which are still frequently used in medical manufacturing, can cause allergic reactions in certain patients. Titanium avoids this issue entirely.

Because of this, titanium is a great material for joints, dental implants, cardiovascular devices, and other implants that need to be used for a long time or for patients who have known sensitivities. This indicates to medical design teams that titanium is a more adaptable and safe material that presents fewer risks to a range of patient populations.

Developments in Titanium Customization and Processing

Applications for titanium are growing more complicated as manufacturing technologies develop further. For instance, patient-specific titanium implants with intricate geometries catered to unique anatomical needs can now be produced thanks to additive manufacturing (3D printing).

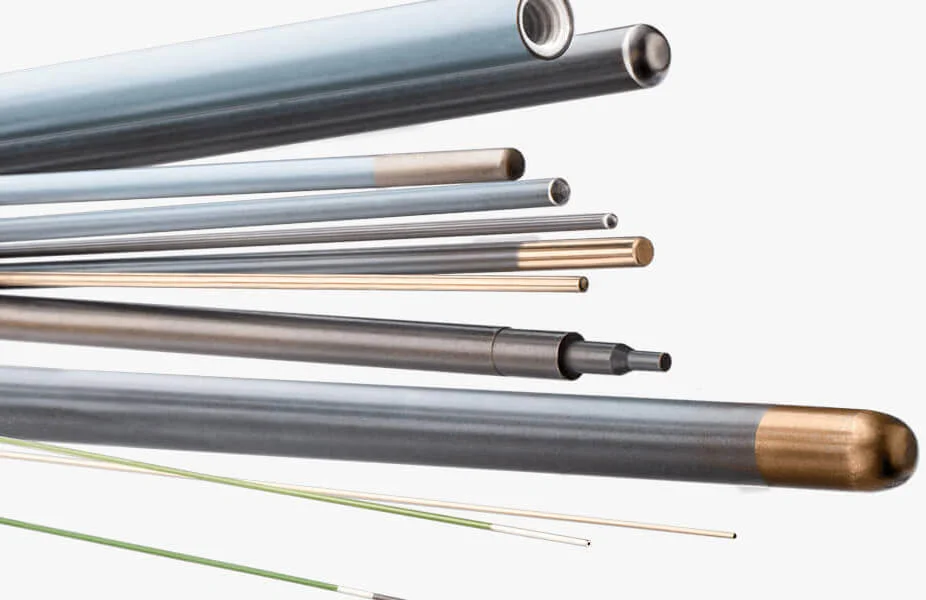

Engineers can also fine-tune the mechanical and biological properties of titanium alloy components—such as endoscopic biopsy needles or devices made with laser cut hypotube—using technologies like surface treatment, laser sintering, and CNC machining.

These tools are facilitating innovation for designers and manufacturers, allowing for the creation of specialized implants and tools to satisfy the changing needs of contemporary medicine.

Titanium's remarkable strength, durability, and compatibility with contemporary medical imaging make it an essential component in the development of minimally invasive surgery, including micro needles and hypodermic needles.

1. Its high strength-to-weight ratio makes it possible to produce ergonomic, small instruments.

2. It improves maneuverability in tight spaces and lessens surgeon fatigue.

3. It is safe for postoperative MRI imaging due to its non-ferromagnetic nature.

Titanium has benefits for supply chain performance and sustainability, despite being frequently disregarded. Titanium can be recycled without compromising performance and is more plentiful than most people think. Titanium can assist producers who are looking for eco-friendly methods in reaching their long-term sustainability objectives.

Furthermore, titanium is now more widely available and reasonably priced than it was previously due to advancements in sourcing and processing technologies, making it a good choice for mid-range medical devices rather than just high-end implants.

This makes titanium a cost-effective option not only for high-end implants but also for widely used devices such as veress needles and disposable trocars.

Titanium's role is anticipated to expand as materials science and surgical efficacy research continue to progress. It is one of the most promising materials for the future because of its remarkable strength, versatility, and biocompatibility. Titanium is the foundation of innumerable advancements in contemporary healthcare, ranging from nanostructured implant surfaces and bioactive coatings to next-generation joint replacements.

To stay ahead of the curve, medical design and manufacturing professionals need to be aware of titanium's biological effects in addition to its mechanical characteristics. Selecting titanium improves quality of life, promotes healing, and ensures safety in addition to durability.