The Ti-Force Titanium Anchor offers strong, biocompatible bone fixation for orthopedic surgeries, ensuring reliable performance in ligament and fracture repairs.

The Ti-Force Titanium Anchor, also called “Rotator cuff suture anchor Ti-Force”, “Titane Suture Anchor” or “The Ti-Force Titanium Anchor”, is an important medical tool made from high-purity titanium alloy. It’s designed to be lightweight yet strong, commonly used in orthopedic surgeries like fixing ligaments and fractures. The anchor has a broad-threaded structure, providing strong attachment to bones and securely fixing connective tissues. Manufactured by Manners Technology, the Ti-Force Titanium Anchor follows international standards in its production process, using materials that work well with the body, ensuring high quality and performance in the medical field.

Ti-Force Titanium Anchors are a type of medical device used in orthopedic surgeries, widely applied in various joint areas such as the shoulder, elbow, and knee. Its main purpose is to repair diseases caused by joint ligament injuries by securely fixing ruptured connective tissues to the bone, providing patients with stable and reliable surgical treatment.

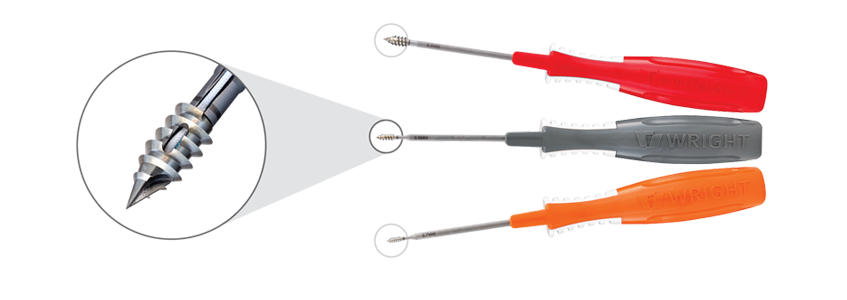

Different models of Ti-Force Titanium Anchors are designed to meet the diverse needs of surgeries, including 2.0mm, 3.5mm, and 5.0mm models, suitable for hand surgeries, Bankart and SLAP procedures, as well as rotator cuff repair surgeries, offering surgeons greater flexibility. Specifically, the anchor’s intuitive color choices and optional needle device make it easier for doctors to perform surgeries in different joint areas.

Ti-Force Titanium Anchors have a wide range of applications, including ligament surgeries such as anterior cruciate ligament (ACL) or posterior cruciate ligament (PCL) repairs, shoulder cuff repairs, or other shoulder joint surgeries, spinal surgeries requiring pedicle screw fixation or other bone fixation procedures, fracture repairs, arthroscopic surgeries, and limb ligament repairs. In these procedures, the anchor fixtures provide highly reliable bone fixation, creating a more precise operating space for surgeons, reducing surgical risks, and achieving excellent therapeutic outcomes.

Manners Technology uses precise manufacturing processes to professionally produce Ti-Force Titanium Anchors. This anchor’s intuitive design and outstanding performance make it an indispensable tool for surgeons during surgeries, ensuring excellent treatment outcomes for patients.

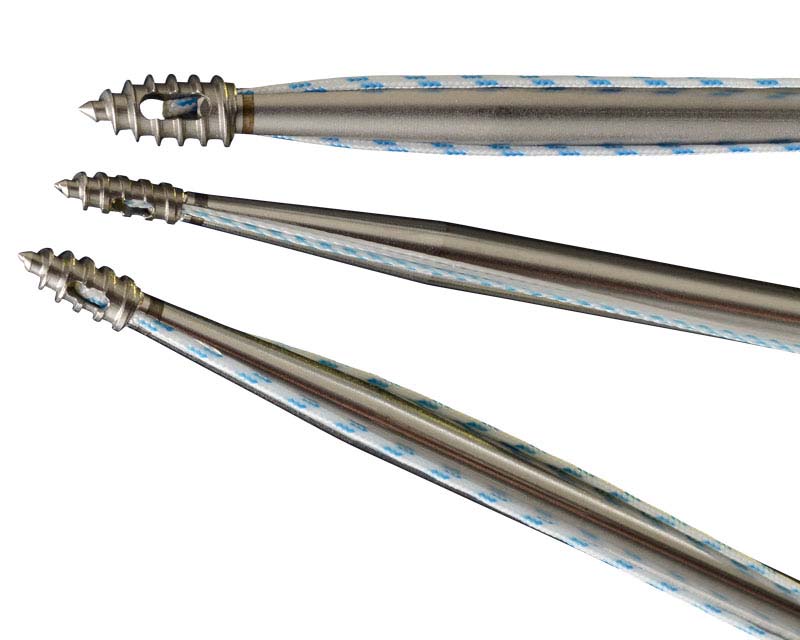

In the manufacturing process of Ti-Force Titanium Anchors, the thread design is a crucial step. The uniqueness of this thread design lies in providing excellent bone fixation and stability for orthopedic surgeries. Specifically, these threads, through their reasonable shape, depth, and spacing, effectively embed into bone tissues, offering outstanding resistance to pullout and rotation. Therefore, during the digital design and simulation phases, engineers use Computer-Aided Design (CAD) software to precisely define the shape, depth, and spacing of the threads. Through digital simulation, they optimize the geometric characteristics of the threads to ensure optimal performance.

Subsequently, Computer Numerical Control (CNC) machining plays a crucial role by cutting according to CAD specifications, ensuring that the threads of each anchor have consistent shape and precision. Thread-forming processes such as rolling or cutting may be required to further refine and strengthen the thread structure. Manners Technology typically takes the anchors to special heat treatment, significantly increasing overall hardness as HRC 58-65, enhancing wear resistance, and enabling the anchors to withstand higher stress and pressure during surgery.

At the same time, Manners employs processes such as anodization, sanding, polishing, and coating treatments, particularly in the threaded sections, to enhance Ti-Force Titanium Anchors. This not only reinforces the anchors’ resistance to corrosion and extends their lifespan but also improves biocompatibility, ensuring the safety of these anchors within the patient’s body. In addition, there is also the use of laser marking to indicate the insertion depth and direction of sutures for Ti-Force Titanium Anchors. The organic combination of these processes ensures that the Ti-Force Titanium Anchor meets high standards in terms of its easy-insertion shape, quality performance, and durability in the medical industry.

Crafted with care by Manners Technology, Ti-Force Titanium Anchors show our outstanding manufacturing capabilities. Using medical-grade titanium alloy and employing highly precise manufacturing processes, we ensure that the product meets the highest standards in terms of wear resistance, hardness, and biocompatibility in the medical industry. We pay attention to every detail, and through special heat and surface treatments, Ti-Force Titanium Anchors become a reliable tool in surgical procedures.