Discover the precision and comfort of Lancet Point Needles, essential for blood sample collection and minimally invasive procedures, manufactured by Manners Technology.

The Lancet Point Needle is a commonly used puncture tool in medicine. Its design focuses on puncture accuracy and patient comfort. The distinctive feature of this needle is its sharp and fine tip, resembling the shape of a scalpel. Its primary function is to perform quick and accurate punctures through the surface of the human body, usually for collecting blood samples, injecting drugs, or performing other minimally invasive medical procedures. Manners Technology has become one of the key suppliers of puncture tools in the medical industry, thanks to its fine manufacturing and sharp cutting capabilities.

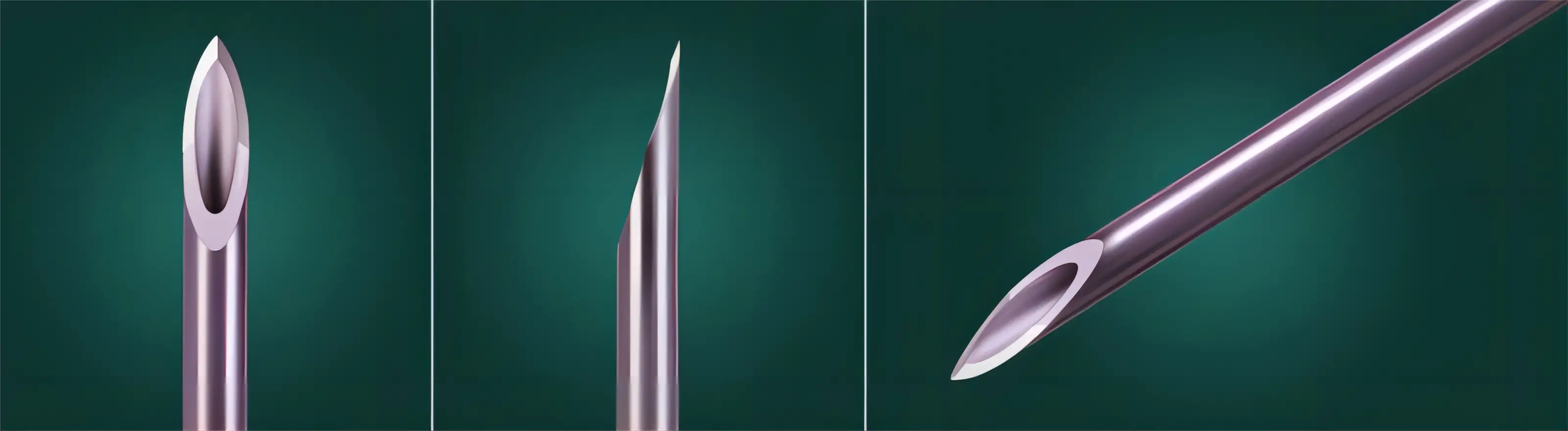

Lancet Point Needle

As a medical device, the Lancet Point Needle’s design is inspired by the traditional "dagger point" shape. Primarily used in minimally invasive medical procedures, this needle plays a key role in biological sample collection and microinjection due to its sharpness and precision. The needle tip of the Lancet Point Needle is tapered and extremely sharp, making the puncture process faster and causing minimal pain to the patient. Its slender body is particularly suitable for scenarios requiring highly precise operations, such as blood collection, minimally invasive surgery, and medical research.

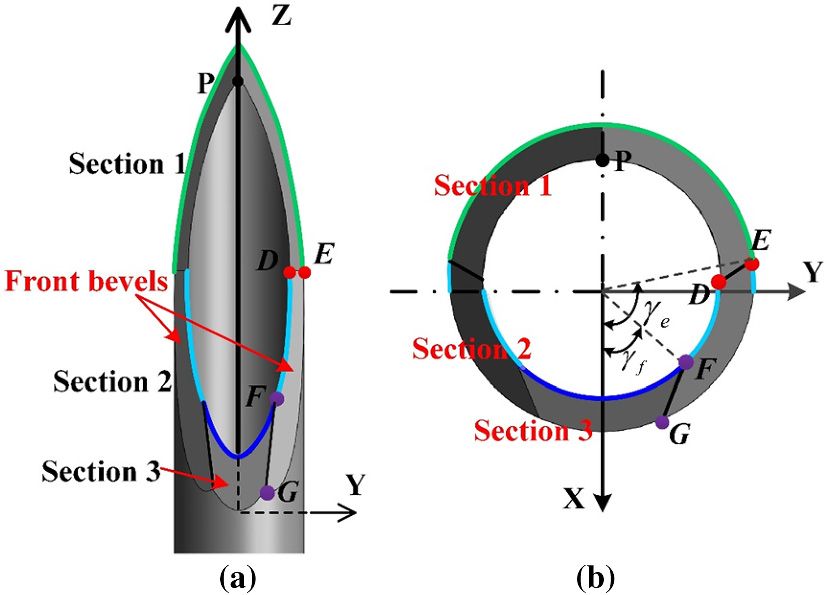

Lancet Point Needle Structure Schematic

In terms of biological sample collection, the Lancet Point Needle reduces patients’ pain with its small size, while its sharpness ensures rapid and effective puncture, providing laboratories with high-quality blood samples. In minimally invasive surgery, doctors can use this needle to perform operations more accurately, reducing surgical injuries and speeding up the recovery process. Additionally, in terms of microinjection, its sharp needle tip and slender body allow minute amounts of drugs or liquids to be injected accurately and quickly into target tissues or blood vessels, providing patients with more precise treatment.

In medical research, researchers often use the Lancet Point Needle to collect cell or tissue samples. Its ultra-sharp tip helps ensure sample integrity and quality, providing researchers with high-quality experimental data. Manners Technology is committed to providing customers with specialized Lancet Point Needles to meet different medical scenarios and individual needs.

Lancet Point Needles have performed well in the medical field, and Manners Technology’s professional medical device manufacturing capabilities provide reliable support for the wide range of applications of these excellent products. To ensure the hardness and corrosion resistance of the needle, high-quality stainless steel material, usually medical-grade stainless steel, is chosen.

Based on the Lancet Point Needle’s design requirements, a team of engineers uses computer-aided design (CAD) software to create an accurate three-dimensional model. Given the sharpness of the needle tip and slender body, the CAD model requires fine adjustments to ensure every detail is fully considered. Next, laser cutting or other high-precision cutting processes are used to cut the stainless steel material into the required shape according to the CAD model design. This step ensures the accuracy of the needle tip geometry and lays a solid foundation for subsequent processing.

Lancet Point Needle 3D view

The Lancet Point Needle is designed to minimize pain and trauma, making it easier to perform fast and efficient blood sampling on patients. Professional technicians use precision machine tools to grind the needle tips, ensuring ultimate sharpness, greater precision, and tighter dimensional control. This step is directly related to the efficiency of the puncture operation and the patient’s comfort.

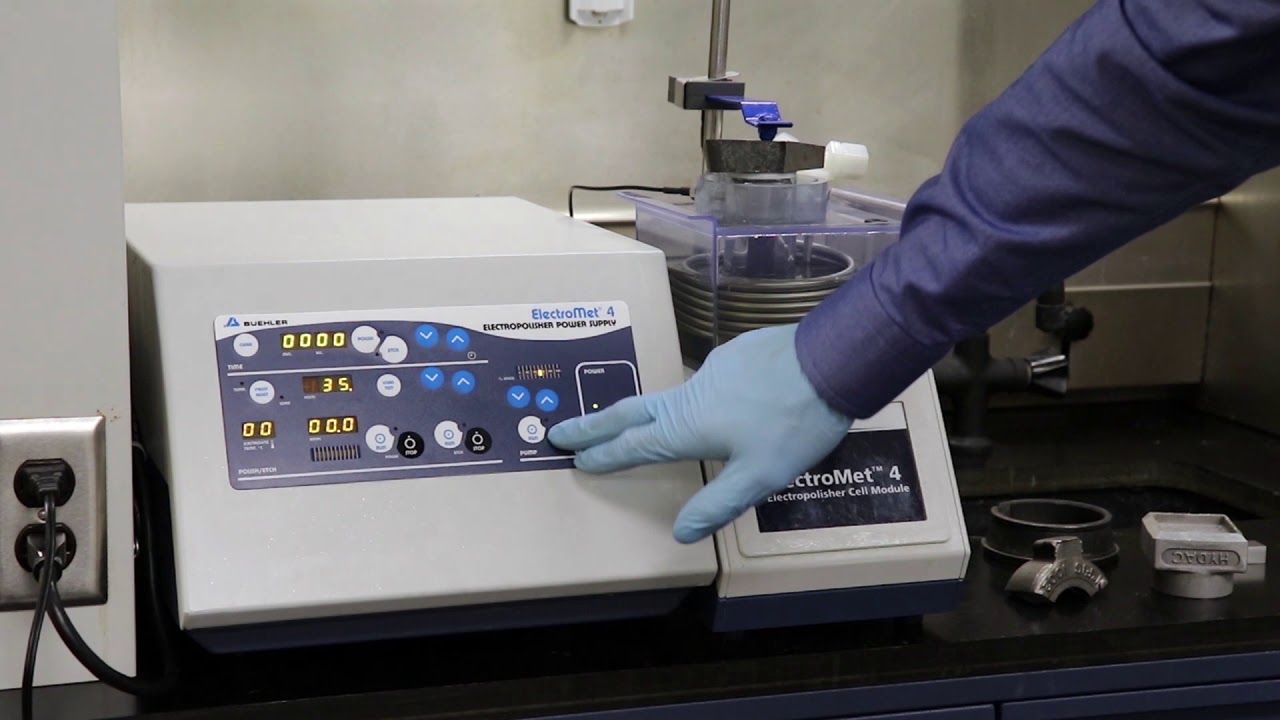

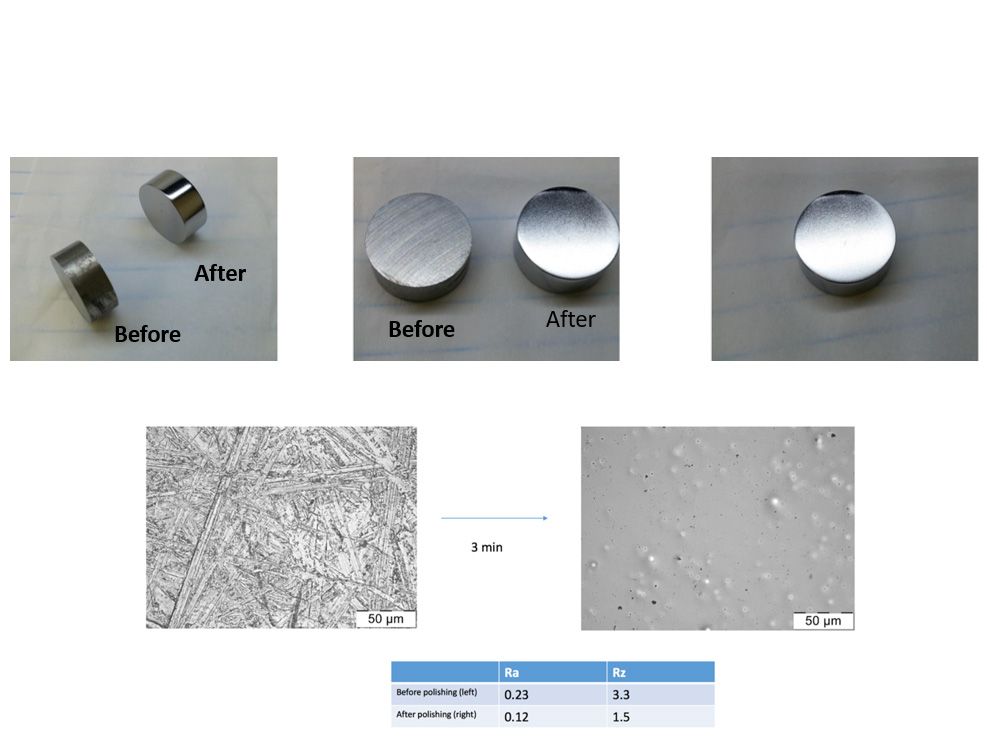

After machining, parts may be stained with oil, lubricants, cutting fluids, etc., and need to be cleaned. The cleaning process removes these impurities and prepares the surface for treatment. Additionally, to improve the surface smoothness and cleanliness of the needle, Manners uses surface treatments such as acid etching and electrolytic polishing. This prepares the surface for subsequent coating or other treatments, reducing tissue damage and improving the smoothness of the puncture, thus providing a better experience for minimally invasive medical treatments. In the final stage of surface treatment, various coatings or penetration treatments may be applied according to customer requirements to enhance the performance of the parts, such as increasing corrosion resistance and hardness.

acid etching

electrolytic polishing

After these steps, a final strict inspection is conducted. This includes inspections of the quality of needle sharpness, appearance, strength, and other functional tests to ensure the high-quality manufacturing of the products. Through this series of precise processing steps, Lancet Point Needles maintain excellent quality and provide reliable tools for minimally invasive medical treatments. This commitment to excellence defines Manners Technology in the field of medical device manufacturing.