Multifunction abutments are versatile dental components used for provisional restorations, definitive prosthetics, and impression-taking, offering precision and flexibility.

Multifunction abutments are a versatile component in dental implantology, designed to serve multiple roles in the restoration process. These abutments streamline clinical procedures by offering adaptability for various prosthetic solutions, making them invaluable in cases requiring efficiency and customization. Their unique design integrates features that enable their use in provisional restorations, impression-taking, and definitive prostheses. By leveraging cutting-edge manufacturing technologies and extensive customization options, Manners empower dental professionals to address the most complex restorative challenges with confidence.

Multifunction abutments are indispensable components in modern dental implantology, offering versatility and precision in a wide range of clinical scenarios. Their adaptable design makes them suitable for various applications, from provisional restorations to definitive prosthetics and impression-taking procedures, enabling clinicians to achieve optimal outcomes in complex cases.

During the healing and osseointegration phase, these abutments provide temporary support for crowns or bridges, allowing patients to maintain aesthetics and functionality while the implant integrates with the bone. Provisional abutments often feature a design that facilitates easy adjustments to accommodate soft tissue healing and alignment with adjacent teeth. In definitive restorations, multifunction abutments serve as the foundation for crowns, bridges, or overdentures, ensuring long-term stability and precise prosthetic alignment. Their compatibility with different implant systems and the availability of various gingival heights and emergence profiles make them ideal for both anterior and posterior restorations.

Another crucial application is their role in impression-taking procedures. Multifunction abutments are often used to transfer the position, angle, and depth of the implant to a working model, ensuring the accurate fabrication of final restorations. Their precision-engineered interfaces, such as hexagonal or conical connections, guarantee a secure fit with the implant and provide an accurate reference for the laboratory process.

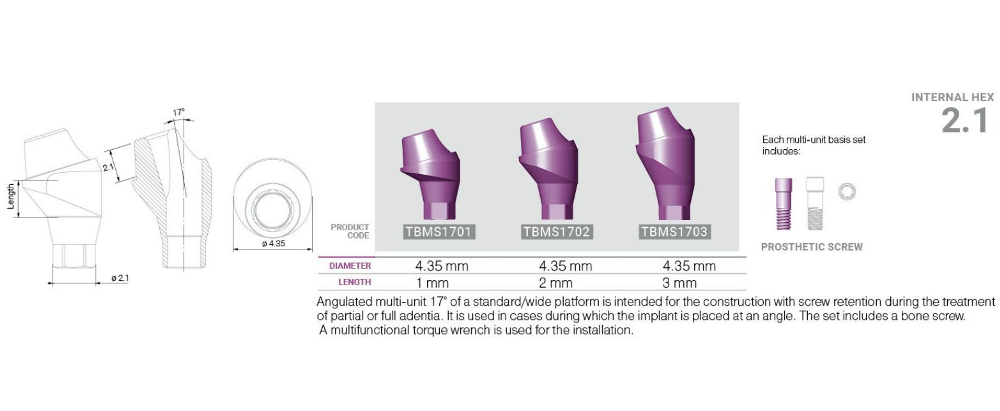

Multifunction abutments are also instrumental in managing challenging anatomical conditions. In cases of angled implants or limited interocclusal space, these abutments provide the flexibility to create functional and aesthetic restorations. For example, customized abutments with specific angulations or extended heights can address unique patient anatomy, enhancing the overall treatment success. The versatility of multifunction abutments extends to full-arch restorations and overdentures. For these cases, abutments act as anchors for bar attachments or locator systems, providing stability and retention for removable prosthetics.

At Manners Technology, we understand the diverse applications of multifunction abutments and are committed to providing high-quality solutions tailored to clinical demands. Our abutments are crafted with precision to ensure reliable performance across all applications, whether supporting temporary restorations, definitive prosthetics, or advanced full-arch solutions.

The production of multifunction abutments demands an exceptional level of precision and expertise to meet their versatile roles in dental restorations. These abutments, utilized for provisional, definitive, and impression-taking applications, require advanced manufacturing techniques to address their complex geometries and stringent functional requirements.

Material selection is a critical first step, as multifunction abutments must balance biocompatibility, strength, and machinability. Titanium and its alloys, such as Titanium Grade 5 (TI-6AL-4V ELI), are widely used for their excellent strength-to-weight ratio, corrosion resistance, and ability to integrate with bone. Zirconia, valued for its superior aesthetics and strength, is employed for anterior restorations, while PEEK (Polyether Ether Ketone) is chosen for lightweight, temporary applications. Each material undergoes rigorous pre-machining treatments by Manners, including annealing and surface conditioning, to enhance performance during manufacturing.

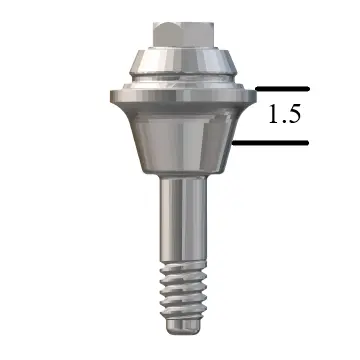

In Manners, Multi-axis Swiss-type lathes, such as Citizen Cincom machines, are utilized to create intricate internal connections, including hexagonal and conical interfaces, ensuring a stable fit with implant fixtures. External contours are shaped to precise dimensions, creating emergence profiles that support soft tissue integration and prosthetic alignment. Retention features, such as grooves or anti-rotational elements, are meticulously carved to enhance stability. Additionally, screw channels with threaded interiors are machined with exceptional precision to ensure proper fixation and alignment during clinical use.

Surface treatments play a vital role in enhancing the performance and longevity of multifunction abutments. Titanium abutments undergo anodization to improve corrosion resistance and osseointegration, while zirconia abutments are polished to achieve a smooth, aesthetic finish that minimizes wear on adjacent teeth. Sandblasting and acid etching are commonly applied to create micro-textured surfaces, promoting soft tissue attachment and reducing bacterial adhesion. After treatment, each abutment is carefully inspected to ensure uniformity and clinical compliance.

Quality assurance is an integral part of the manufacturing process. Dimensional inspections using Coordinate Measuring Machines (CMM) verify internal and external geometries, maintaining tolerances within ±2 microns. Interface testing ensures that abutments securely connect with implants, while optical and tactile inspections confirm surface smoothness and uniformity. These rigorous processes guarantee the reliability and performance of each abutment in diverse clinical applications.

At Manners Technology, we specialize in the precision manufacturing of multifunction abutments, leveraging advanced five-axis lathe machining, state-of-the-art surface treatments, and comprehensive quality control systems. By delivering reliable, versatile solutions, we empower dental professionals to address the complex demands of modern implantology with confidence.