Explore the benefits of Ti-Force Titanium Anchors for orthopedic surgeries, including superior fixation and stability. Learn about their versatile applications and manufacturing process.

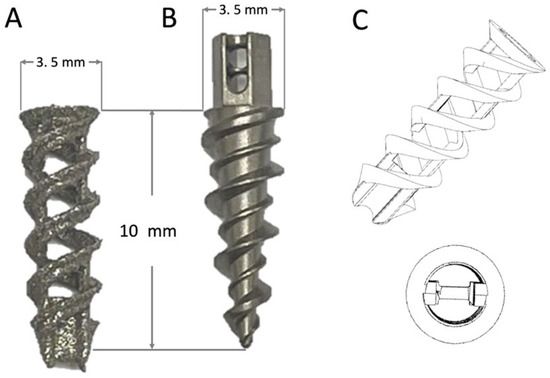

The Ti-Force Full Thread Anchor, also known as “Rotator cuff suture anchor (Ti-Force Full Thread)”, is a surgical implant made of high-purity titanium alloy. Its distinguishing feature is the fully threaded design, including an integral thread covering the implant surface.

▲ Ti-Force Full Thread Anchor

This design is designed to provide stronger fixation and better implant stability and is commonly used in surgical procedures such as thread-reinforced fracture treatment, intraosseous fixation, and bone cutting. Manners Technology offers a total solution in sports medicine, with titanium anchors being one of the flagship products. These anchors boast excellent biocompatibility and high strength. When paired with 2# or 2-0# UHMWPE ultra-high-molecular-weight polyethylene sutures, they become a safer and more effective treatment option in orthopedic surgeries.

▲ Titanium Anchors with Polyethylene Sutures

Ti-Force Full Thread Anchors are surgically designed, fully threaded bone fixation devices that play a critical role in multiple surgical and orthopedic applications. Through the unique combination of an internal drive mechanism and the FiberWire suture eyelet, the anchor achieves continuous threads along its entire length. This design allows the implant to be inserted into the cortical bone surface during surgery, providing excellent fixation strength and stability while avoiding the potential “pull-back” effect that may occur with traditional anchors.

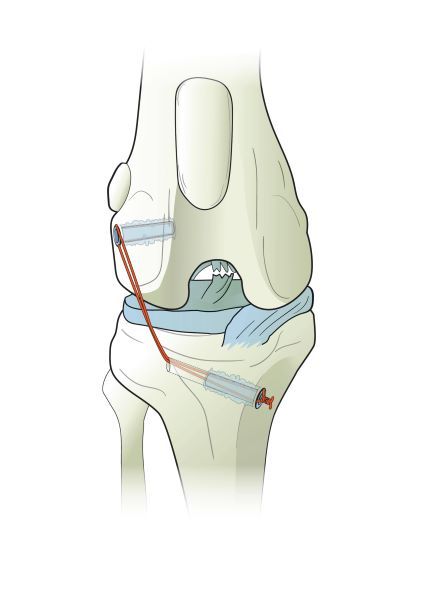

Specifically, Ti-Force Full Thread Anchors can be used to repair the anterior cruciate ligament (ACL) or posterior cruciate ligament (PCL) in joint ligament repair, providing strong bone fixation through a fully threaded design, helping to restore joint stability. During shoulder surgery, especially rotator cuff repair or other shoulder surgeries, this anchor provides solid bony fixation, ensuring successful surgery and supporting the stability of the shoulder structure.

▲ Ti-Force Full Thread Anchors used in joint ligament repair

Ti-Force Full Thread Anchors also play a key role in spinal surgery, where they are used for pedicle screws or other situations where bone fixation is required, ensuring the success of spinal surgery and maintaining the stability of the bone structure. In addition, anchors can be used to repair ligaments in other parts of the limbs, such as wrists, ankle joints, etc., to provide stable bone fixation.

In arthroscopic surgery, Ti-Force Full Thread Anchors can be used to fix and reconstruct joint structures, such as repairing damage to the meniscus or other joint tissues. In fracture repair, anchors hold the fracture fragments in place, providing additional support and promoting healing.

Overall, Ti-Force Full Thread Anchors provide doctors with reliable bone fixation and support through their fully threaded design, making them suitable for a variety of complex bone repair and reconstruction surgeries. Manners Technology will produce products of different specifications according to corresponding customer needs and specific surgical applications.

Ti-Force Full Thread Anchors are surgical implants that incorporate highly precise craftsmanship and advanced technology in their design and processing. They are typically made from a high-quality medical-grade titanium alloy (ASTM-F136 Grade 5 Eli). This titanium alloy, which is widely used in the medical field, has outstanding performance in the manufacture of implants. It has excellent mechanical properties, corrosion resistance and biocompatibility, and has become the first choice material for the production of artificial joints, implantable stents and other medical devices.

▲ Ti-Force Full Thread Anchors

The implant is designed with careful consideration for a diameter of 4.5-5.5 millimeters, a fully threaded structural design, and two circular holes on the anchor intended for more flexible suture manipulation. Before machining begins, Manners Technology performs computer-aided design (CAD). Through CAD, key parameters such as the geometry and full-thread structure of Ti-Force Full Thread Anchors are accurately designed based on surgical requirements and the characteristics of the implantation site. Computer numerical control (CNC) machines are then used for precision machining. According to the CAD drawings, the titanium alloy raw materials are precisely cut into the shape of the Ti-Force Full Thread Anchor that meets the design requirements through highly automated CNC processing. This process not only ensures the consistency and accuracy of each anchor, but also improves production efficiency and manufacturing controllability.

The hardness of titanium alloy is relatively low, typically ranging around 250~350 HV after processing. The density of titanium alloy is approximately 4.51 g/cm³, which is only 60% of that of steel. Despite its lower hardness, some high-strength titanium alloys surpass the strength of many alloy structural steels. Therefore, the strength-to-density ratio of titanium alloy is much higher than that of other metal structural materials, allowing for the production of components with high strength, good rigidity, and lightweight properties. In this process, by precisely controlling temperature and time, Manners performs heat treatment to adjust the hardness and toughness of the Ti-Force Full Thread Anchors, ensuring that it can withstand external stress after implantation while maintaining sufficient toughness to prevent fractures under stress.

▲ Anchors with Different Materials

Finally, the production of Ti-Force Full Thread Anchors involves a series of detailed steps, including grinding, swaging, drilling, marking, surface treatment, cleaning, and quality inspection. These steps ensure that each implant meets the highest standards and customer needs for a variety of surgical applications. It is worth mentioning that, as a professional manufacturer, Manners Technology strictly controls every processing step to produce the excellent quality of Ti-Force Full Thread Anchors and bring reliable repair solutions to surgical operations in the medical field.