Discover the versatility of suction tubes, essential medical devices for fluid extraction, airway clearance, and surgical site maintenance, crafted with precision for reliability.

The Suction Tube, also known as “suction tubing”, “suction catheter” or “aspirators”, is well-designed tube-like medical device typically made of medical-grade materials such as medical plastic, silicone, or stainless steel. These tubes allow healthcare professionals to insert them into a patient’s mouth, nose, trachea, etc., and extract excess fluids using negative pressure, ensuring unobstructed airways and promoting recovery. Manners Technology is state-of-art in the field of medical device manufacturing, specializing in the production of high-quality suction tubes parts.

Suction tubes, also known as aspirators, serve critical roles in medical settings, addressing various healthcare needs. Firstly, they are instrumental in maintaining airway patency during respiratory emergencies, surgeries, or instances where patients have excessive secretions. By effectively clearing the respiratory tract of secretions, suction tubes ensure smooth and unobstructed breathing for the patients.

During surgical procedures, these catheters play a vital role in ensuring surgical site cleanliness. By efficiently removing blood, tissue fragments, and other fluids from the surgical site, they aid in maintaining a clear surgical field. This clarity is crucial for surgeons to operate with precision and accuracy.

In gastrointestinal surgeries or examinations, suction tubes are used to extract gastric fluids or excess liquid, facilitating the procedure and providing a clearer view for medical professionals.

Furthermore, suction tubes are employed in oral and dental care, particularly during surgical interventions. They effectively clear blood or saliva produced during oral and dental surgeries, ensuring that the surgical area remains dry and well-maintained.

In summary, suction tubes are versatile medical tools, essential for maintaining airway patency, preserving surgical site cleanliness, aiding gastrointestinal procedures, and ensuring a dry surgical environment in oral and dental care. Their multifaceted applications make them indispensable in various medical scenarios.

There are several types of suction tubes used in medical settings, each designed for specific purposes and applications. These tubes are categorized based on their intended use and design features, catering to different medical scenarios.

In the realm of gastrointestinal suction tubes, the Gastric Suction Tube plays a crucial role in suctioning the contents of the stomach, aiding in various medical procedures. On the other hand, the Nasogastric Suction Tube is designed to be inserted through the nose into the stomach, providing a route for suctioning and drainage, particularly useful in cases where gastric drainage is required.

For addressing respiratory tract needs, Tracheal Suction Tube is essential for efficiently clearing secretions and maintains a patent airway in the trachea, contributing to effective breathing and pulmonary hygiene. Similarly, the Thoracic Suction Tube serves its purpose in the chest cavity, allowing for suctioning and drainage in thoracic surgeries and related medical interventions.

In the domain of excretory fluids, the Urinary Suction Tube is tailored to effectively suction urine from the urinary tract, ensuring the proper management of urinary systems in healthcare contexts.

Multi-functional suction tubes like the Poole Suction Tube, with their design featuring multiple channels, can be utilized for various suction needs across diverse medical procedures. The Sump Suction Tube is another type with a dual-channel design, commonly used in abdominal surgeries, maintaining consistent suction and preventing blockages.

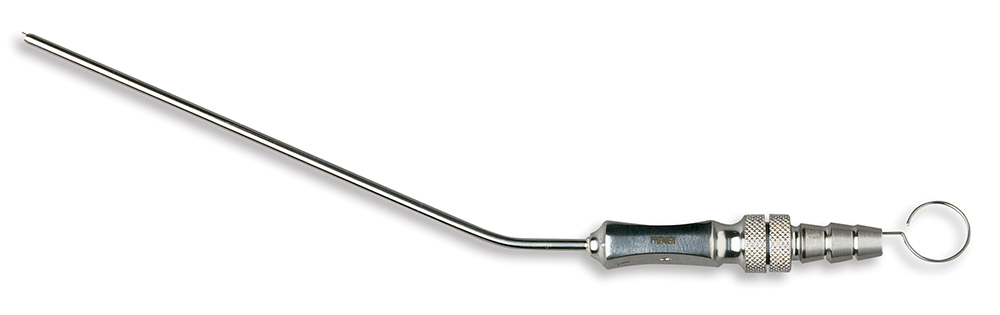

For specific surgical or trauma-related applications, specialized suction tubes come into use. The Trauma Suction Tube is specifically designed to handle trauma scenarios, aiding in the swift removal of excess fluids and materials. On the other hand, the Frazier Suction Tube is characterized by its slender tip, offering precise suction in delicate surgeries, often found in neurosurgical and ophthalmic procedures.

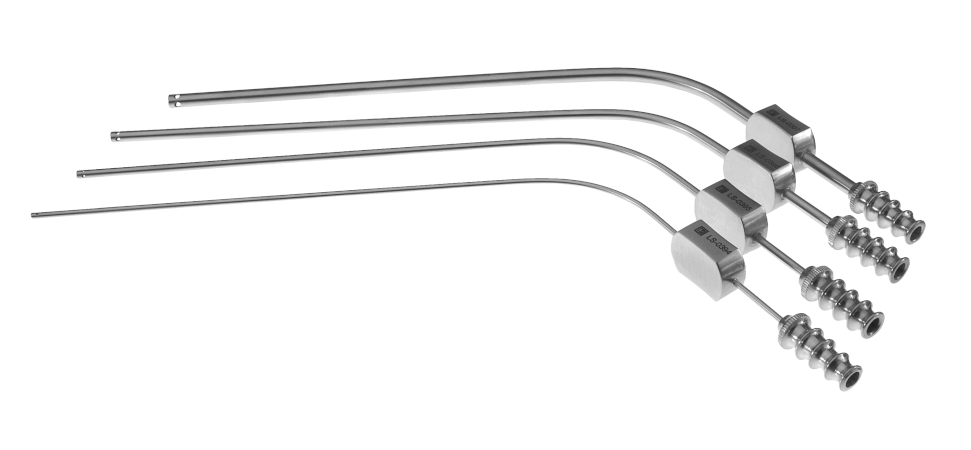

In summary, each suction tube with its designated medical purpose, optimizes patient care and enhances surgical and medical outcomes. Manners can produce metal parts of Yankauer, Poppen Suction Tube, and various types of suction tubes. Our commitment to innovation and precision has positioned us as a trusted provider of the parts of suction tubes that meet the highest industry standards and customized requirements.

The main part of the suction tube is mainly made of medical-grade plastic, while metal materials may be used in specific parts to provide necessary support and strength. The suction tube tip, a critical component of the suction tube, is positioned at the tube’s end, making direct contact with bodily fluids or foreign matter. This part is pivotal in aspirating and removing unwanted substances.

In certain cases, the suction tube tip may utilize metal, particularly stainless steel, to reinforce its structural integrity and longevity, while ensuring a smooth surface to minimize friction and resistance. Because stainless steel suction tube tips can withstand high-temperature sterilization processes, ensuring thorough cleaning and disinfection and reducing the risk of infection. It allows for the design of a robust structure for the suction tube tip or nozzle, enabling it to withstand significant negative pressure while maintaining its shape and functionality. Manners Technology machines stainless steel, Ni-Ti or other medical-grade metals for the suction tube (replacement) tip which can ensure its structural stability and durability while maintaining biocompatibility and ease of cleaning.

Manufacturing of suction tubes involves precision engineering and adheres to stringent quality standards. Before processing begins, an adequate amount of materials are carefully prepared based on the intended use and functionality of the suction tubes and cut to the required dimensions and shapes based on design specifications. Cutting is achieved through laser cutting in Manners Technology.

The next step involves rough machining, commonly using methods such as milling, turning, drilling, etc,. These processes aim to roughly shape the raw material into the desired form and remove excess material while maintaining its flexibility and strength. After the initial shaping, more precise machining takes place, such as grinding, turning, milling, etc. The objective during this stage is to further refine the machining, ensuring the dimensions and surface quality of the components meet design requirements. It is worth noting that these operations are automatically processed by one-time disposable core walking machines in Manners, demanding excellent equipment and cutting edge technology.

Some parts may require welding to connect pipes or assemble individual components to ensure the structural integrity and proper function of the device. Welding techniques need to be precise to ensure the strength and aesthetics of the welding points. Subsequently, assembly and checks are carried out to ensure the correct connection of components. Then, the semi-finished components undergo surface treatments like polishing, pickling, electroplating, etc., to enhance their appearance and corrosion resistance.

Finally, rigorous quality checks will be taken to ensure the suction tube parts meet the required standards for safety, functionality, and hygiene. Dedicated to high precision and advanced technology, Manners Technology will continue to contribute significantly to the medical field by ensuring the availability of reliable and efficient suction tubes.