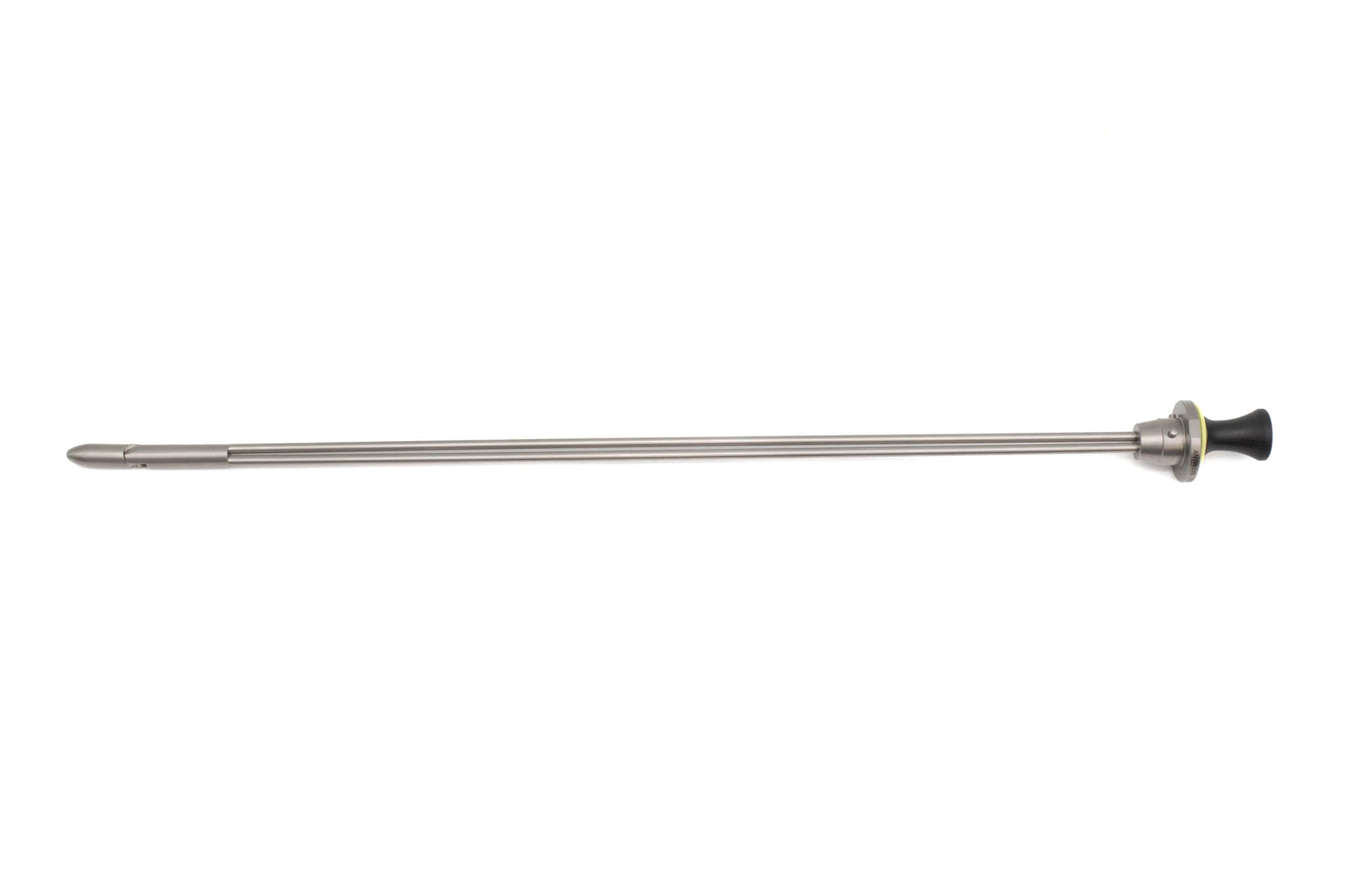

Discover the Visual Obturator Tube, a medical instrument enhancing precision and visibility in minimally invasive surgeries, reducing tissue damage and recovery time.

The Visual Obturator Tube, also known as “Visual Obturator Shaft”, is a cutting-edge medical instrument engineered to provide unparalleled visibility and precision in minimally invasive surgical procedures. In the realm of minimally invasive surgery, technological advancements continue to redefine the boundaries of what's possible. One such innovation that has significantly impacted the field is the Visual Obturator Tube. This remarkable tool functions as a conduit for accessing surgical sites while offering real-time visual feedback, significantly enhancing surgical accuracy.

The versatility of the Visual Obturator Tube spans various medical disciplines. In laparoscopic surgery, surgeons use it for procedures like organ biopsies, tumor resections, and gallbladder removals. In endoscopy, gastroenterologists and pulmonologists rely on its articulation and clear vision for remote examinations. In orthopedic Surgery, even in limited spaces, it aids in navigating joints and performing intricate repairs. In Urology, enhances visualization during prostatectomies and nephrectomies. In gynecology, precise visualization in procedures like hysterectomies and ovarian cystectomies.

In minimally invasive surgery, the Visual Obturator Shaft offers significant advantages. First, it provides precise viewing and navigation capabilities, allowing surgeons to perform complex tasks with confidence. Second, it reduces incisions and tissue damage, helping to speed up the patient's recovery process and minimize scarring. At the same time, improved visibility usually means shorter surgery times and reduced anesthetic exposure and risk of complications for patients. Most importantly, the use of this device enhances patient safety by reducing the risk of accidental tissue damage or injury.

Manners Technology’s manufacturing process of the Visual Obturator Tube / Visual Obturator Tube Shaft seamlessly blends advanced technology, precision engineering, and an unwavering commitment to patient safety and surgical precision. State-of-the-art equipment produces components to exacting specifications, ensuring consistent quality and performance. Rigorous quality control measures meet regulatory standards to ensure maximum patient safety.

It all begins with the careful selection of materials. Advanced metal stainless steel and other medical grade alloys are chosen for their durability, biocompatibility, and resistance to sterilization procedures. These materials are tailored to meet the specific requirements of the Visual Obturator Tube, ensuring optimal performance and safety.

Engineers then employ state-of-the-art CAD software to craft a detailed digital blueprint of the instrument. This includes the design of the tube, articulation mechanism and any disposable components. The CAD design serves as the foundation for the physical instrument, guaranteeing precision and consistency in every detail.

The heart of the manufacturing process is precision machining. Computer Numerical Control (CNC) machines are used to carve out the various components from the selected materials. The entire tubing is loaded into an automatic feeder, which then precisely feeds it into a five-axis machining center. Within this center, the material undergoes a series of automated processes, including cutting it to size, drilling holes, and chamfering all holes to remove burrs.

Once this machining phase is completed, the product undergoes two stages of centerless grinding: a rough grinding pass followed by a precision grinding pass. These grinding steps ensure a smooth and polished surface, free from imperfections like pinches or dents. Subsequently, the tube undergoes ultrasonic cleaning, guaranteeing both the interior and exterior surfaces are smooth and glossy. The interior roughness can achieve levels as low as Ra0.4. This meticulously organized manufacturing process ensures the high-quality production of the Visual Obturator Tube, meeting stringent standards for precision and surface finish.

Manners demands exceptional precision, as each part must conform precisely to the CAD specifications. The end result is a set of components that fit together seamlessly and perform with remarkable accuracy. In these steps, from material selection to precision machining, the Visual Obturator Tube takes shape, embodying the fusion of cutting-edge technology and precise craftsmanship in Manners Technology.