| Product Name | Radiofrequency Transseptal Needle |

|---|---|

| Application | Transseptal Puncture (TSP) |

| Tip | Rounded atraumatic |

| Materials | Stainless Steel 304, 305 |

| Hardness | HRC 22-25 |

| Diameter | 0.6mm, 0.7 mm |

| Length | 6.5 mm |

| Tolerance | +/-0.01mm |

| Manufacturing | Sliding Headstock Lathe |

| Certification | ISO 9001:2015, ISO 13485 |

| Facilities | Citizen Cincom R04 |

| Packing | PP bag or tailor-made packing on request |

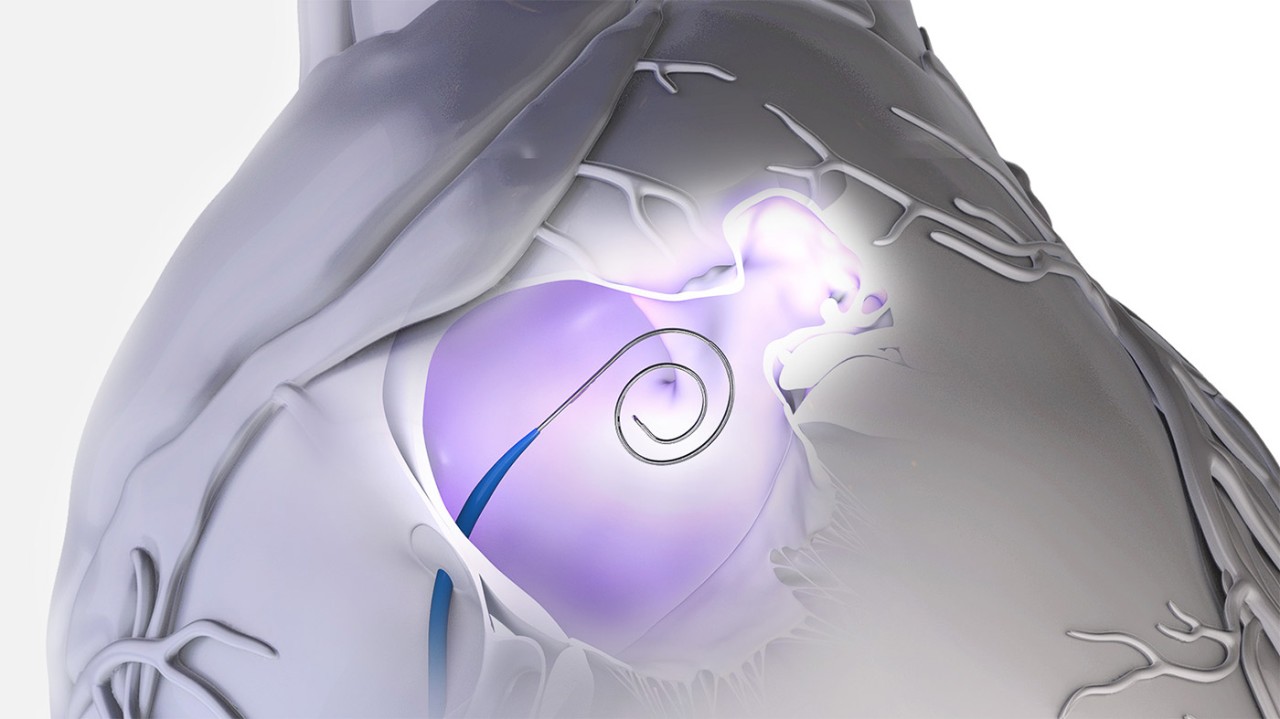

Standard approaches to transseptal puncture (TSP) for left atrial (LA) procedures involve mechanical or radiofrequency (RF) energy-assisted methods. Mechanical needles pose risks like tissue perforation and cardiac tamponade, often ineffective for challenging septal anatomies (i.e., fibrotic, aneurysmal, prior transseptal cannulation). In contrast, RF TSP platforms like the NRG transseptal needle and VersaCross RF solution (by Baylis Medical/Boston Scientific), improve efficacy, safety, and efficiency.

Unlike sharp-tipped mechanical needles, which can create plastic particles as they advance through a sheath and dilator, the blunt-tip RF needle eliminates this risk and prevents potential embolic complications. By delivering a short, highly focused pulse of radiofrequency energy, the RF needle ensures precise and controlled punctures. It improves crossing success rates and reduces procedure time by effectively crossing aneurysmal and fibrotic septa with minimal force. The rounded, atraumatic tip allows for fine-tuned positioning and reduces the risk of serious complications. In addition, the RF needle's radiopaque marker makes it easy to visualize on mapping systems, further enhancing procedural accuracy and safety.

Manners Technology, a partner of Baylis Medical/Boston Scientific, is currently producing the RF transseptal needle, advancing procedural outcomes. Our Radiofrequency Transseptal Needle is made of 304 and 305 stainless steel with a hardness of HRC 22-25. Featuring a rounded atraumatic tip, it is available in diameters of 0.6mm and 0.7mm, and a length of 6.5mm. This needle is manufactured with precision on our Sliding Headstock Lathe (Japan Citizen Cincom R04).

The compact R04VI by Citizen is designed for high-speed, high-precision machining of tiny precision parts, including our Radiofrequency Transseptal Needle. With a rotary guide bushing unit, it achieves metal cutting at speeds up to 80,000 rpm, ensuring an accuracy of 0.01mm and angular tolerance of 0.1°. Specializing in producing small-sized products with smooth surfaces and low roughness (Ra<0.4μm), it meets the high-quality finish required for medical applications.

Next, the needle undergoes electropolishing per ASTM B912 standards. This electrochemical process enhances corrosion resistance and removes surface defects like burrs and microcracks. Electropolishing precisely removes a microscopically thin layer of surface material, with removal controlled to within +/- .0001 inches, depending on the alloy. The result is a smooth bevel surface finish of 0.25 microns Ra.

Following electropolishing, the needle is subjected to ultrasonic cleaning. Ultrasonic cleaners emit up to 40 thousand sound pulses per second, each pulse providing cleaning action as it impacts the needle surface. This high-frequency wave action ensures the efficient removal of contaminants, surpassing the effectiveness of other cleaning methods.

Finally, the needle undergoes rigorous quality testing to ensure its dimensional accuracy, structural integrity, and adherence to specifications. Each step in the manufacturing process contributes to the Radiofrequency Transseptal Needle's exceptional quality, durability, and performance, making it a reliable tool for medical practitioners in various procedures.