Discover the Peek-Force Plus Screw Type Suture Anchor, designed for secure soft tissue-to-bone fixation in orthopedic surgeries, offering strength and biocompatibility.

The Peek-Force Plus Screw-type Suture Anchor is an implant commonly used in orthopedic surgeries. It is made of high-strength polyetheretherketone (PEEK) material and has a threaded anchor body and adjustable absorbable sutures. Its strong PEEK construction and unique thread design allow it to play a key role in surgery, providing a strong connection between soft tissue and bone, and is suitable for joint stability repair and other orthopedic surgeries. Peek-Force Plus Screw-Type Suture Anchors are carefully manufactured by Manners Technology through professional machining processes and strict quality control to ensure that each product meets the highest standards.

As an innovative orthopedic implant, its reliability and biocompatibility make it the tool of choice for orthopedic surgeons performing complex surgeries. In different surgical scenarios, the Peek-Force Plus Screw Type Suture Anchor provides doctors with a powerful tool to help patients achieve the recovery and reconstruction of bone structure.

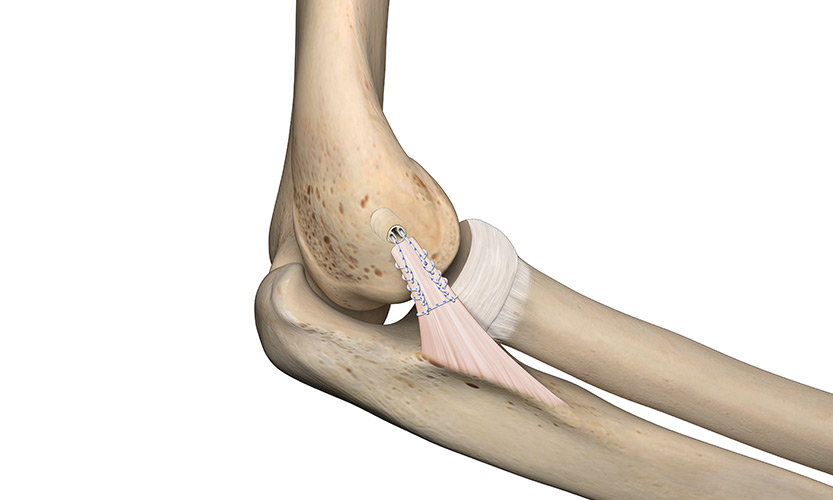

In shoulder surgery, Peek-Force Plus Screw Type Suture Anchors are widely used to repair rotator cuff tears. Their threaded anchors reliably secure soft tissue, while the adjustable absorbable sutures provide powerful suturing, providing patients with a durable and reliable repair. Ligament injuries are a common problem in joint injuries, and the Peek-Force Plus Screw Type Suture Anchor plays a key role in reconstructive surgeries for ligament injuries in the knee and other joints. Its design provides a stable bone-ligament connection and accelerates patient recovery. For joint stability repair, the Peek-Force Plus Screw Type Suture Anchor provides a reliable solution. During surgeries on joints such as elbows, shoulders, feet and ankles, the threaded anchors can be firmly fixed to ensure rapid recovery of joint stability.

The design of the Peek-Force Plus Screw Type Suture Anchor makes it an ideal choice in the treatment of some fractures, especially when it is necessary to repair the complex connections between bone and soft tissue. It provides adjustable suturing force and promotes healing at the fracture site. Doctors can choose the appropriate implant based on the patient’s specific conditions to provide consistent and excellent performance for different parts of the surgery.

Overall, the Peek-Force Plus Screw Type Suture Anchor has diverse applications in orthopedic surgery, providing physicians with a reliable tool to help patients achieve the restoration and stabilization of bone structure. Manners Technology provides reliable solutions for surgical procedures in the medical field, providing patients with safe and effective treatment options through advanced medical implants.

The unique design and characteristics of the Peek-Force Plus Screw Type Suture Anchor directly affect its processing steps. As a threaded suture anchor, it is made of high-strength materials such as polyetheretherketone (PEEK). This material has excellent mechanical properties, resulting in good biocompatibility, corrosion resistance and tensile strength of the anchor. The anchor’s shape is designed with biomechanics in mind to provide excellent implantation results. Therefore, in the manufacturing process, the selection of materials and the design and machining of shape and size are the first steps to be considered.

The design features of the product include a threaded anchor body, which securely embeds into the bone, while the fixation screw is used to stabilize soft tissues, making a reliable ligament or tendon connection. Achieving this function accurately requires highly precise thread processing. CNC machining technology plays a key role in ensuring thread consistency and accuracy for each product. The design of the thread also needs to consider its close integration with the bone structure to ensure the reliability of the implant.

In orthopedic applications, the hardness of implants is crucial. In the manufacturing process of the Peek-Force Plus Screw Type Suture Anchor, it is essential to ensure it reaches the appropriate hardness level, meeting the high standards for implant strength and durability in orthopedic surgeries. Heat treatment is a critical step to ensure that the Peek-Force Plus Screw Type Suture Anchor attains the desired hardness. Proper heat treatment can enhance the mechanical properties of PEEK, ensuring the product has sufficient strength and stability during use. It is worth noting that controlling heat treatment parameters is crucial to ensuring the consistency of hardness for each product. Since the implant is primarily made of polyetheretherketone (PEEK), the manufacturing process must consider the unique properties of this high-performance plastic. While PEEK is a suitable material for implantation in the human body, with excellent biocompatibility and strength, temperature control is necessary during processing to prevent overheating and material deformation. Manners Technology, through precise heat treatment and material control, will ensure that the product achieves the ideal hardness required for orthopedic surgeries.

Every step of the process requires attention to details to ensure that the final implants reach the exceptional level of performance during surgeries. Relying on advanced production equipment and rich experience, Manners Technology is committed to providing orthopedic surgeons with high-performance, reliable medical devices that meet clinical needs, helping the medical industry achieve better surgical results and improving patients’ treatment experience.