Explore Punch and Cannula Needles for egg vaccination, designed for precision and contamination prevention, improving bird health and production efficiency.

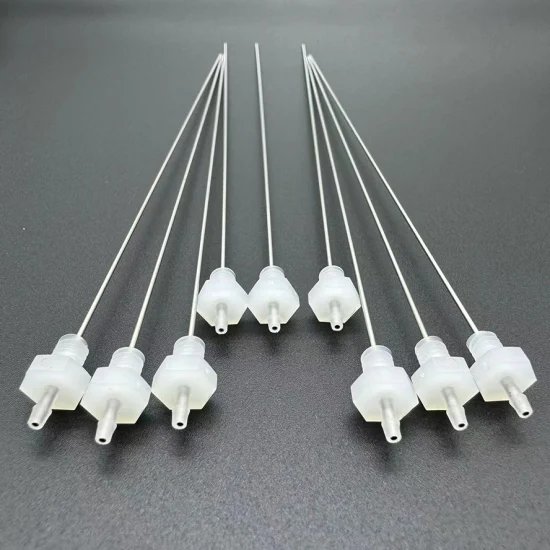

The Punch Needle and Cannula Needle, also referred to simply as “punch” and “needle”, or “punch needle” and “long needle”, are typically crafted from stainless steel AISI 304, 316L, Ni-Ti, L605, and other alloy materials, often complemented by engineering plastics. These specialized needles are designed for egg vaccination purposes. At Manners Technology, we utilize these materials to manufacture Punch Needles and Cannula Needles, employing automated precision equipment.

These needles, along with other peripheral products, play a vital role in egg identification, removal, vaccination, and transfer processes. Our solutions find applications in hatcheries, laboratories, and various other settings, aiding in efficient and precise operations.

The Punch Needle and Long Needle significantly enhance birds’ immune response to vaccinated diseases and contribute to improved weight gain from their food consumption. This, in turn, helps in reducing mortality and condemnations during the slaughterhouse process. These needles play a crucial role in preventing commercial losses at all stages of the production cycle, promoting optimal bird development.

The Punch Needle is designed to be installed in a specialized tooling injector to create a hole in the eggshell, while the Long Needle is inserted into this tooling injector to reach inside the egg for vaccine injection. During this process, the Long Needle, which remains clean, passes through the punch cannula and then enters the egg, ensuring that it does not come into contact with the potentially contaminated eggshell. The double needle penetration technology further prevents contamination from one egg to another.

At Manners Technology, our punch needles are engineered to withstand the force required to break the eggshell. Moreover, both needles exhibit resilience to various chemical liquids, including alcohol, sodium hypochlorite, cleaners, and more.

When selecting materials, our priority is to choose the most suitable, safer, and efficient options. For the needle part, we predominantly use stainless steel 304 or 316. It’s noteworthy that 316 is often a superior choice due to the presence of molybdenum and a higher nickel content (12%) compared to 304 (8%). This composition makes 316 more resistant to corrosion, especially chloride corrosion.

On the other hand, for the plastic base, we have a range of material options to choose from, including nylon, ABS, PVDF, KYNAR, and more. Let’s take ABS as an example, known for its exceptional mechanical properties, dimensional stability, processing ability, chemical resistance, and an appealing, high-quality appearance.

Both the punch needle and long needle are meticulously assembled through injection molding, involving a needle and a plastic base. Long needles undergo a precise manufacturing process using CNC grinding machines to process the tube with a bias grind. Conversely, short needles are crafted using a 5-axis CNC centering machine, performing all partial grinding and small hole operations in a single process. The product accuracy is finely controlled at ±0.01mm.

Furthermore, all long and short needles undergo a meticulous post-processing phase to ensure superior quality. This includes the removal of any cloak to eliminate residue, followed by ultrasonic cleaning, passivation, and electrolytic polishing. These processes guarantee the cleanliness of the needles, meeting or even exceeding customer requirements.

Our strength lies in our ability to customize special punch and needle designs, providing a wide array of processing possibilities. Coupled with a reliable supply chain and stable materials, Manners Technology ensures that every product is completed to your exacting standards, offering peace of mind to all our customers.