Learn about pump impellers for continuous blood flow, essential in medical devices like VADs, designed to ensure smooth blood circulation in heart support systems.

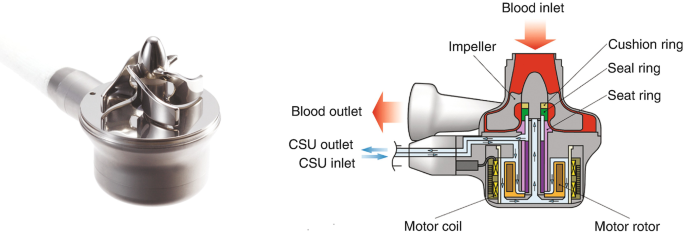

The pump impeller for continuous blood flow, also known as “continuous flow rotary blood pumps”, is a crucial component in medical devices, specifically designed to assist in pumping blood in the heart or as a part of an artificial heart. It is a rotating component, typically made of metal, with unique blade or vane structures. This unique design allows it to rotate within the pump, propelling the blood to flow smoothly. In medical devices like Ventricular Assist Devices (VADs) or artificial hearts, the pump impeller plays a critical role in ensuring a continuous flow of blood, maintaining heart function.

Initially, during the early stages of blood pump development, researchers contemplated creating displacement pumps to deliver pulsatile flow. However, studies have shown that pulsatile flow is not a “must-have” requirement. Compared to pulsatile flow, continuous flow can effectively supply blood to all parts of the body for many years. As a new and efficient technology, continuous flow, being valveless, results in a gentler hemolysis process compared to pulsatile pumps.

Continuous flow pumps come in two main types: centrifugal and axial pumps. Centrifugal pumps provide higher pressure at lower flow rates, while axial pumps offer a higher flow rate with lower pressure increases. In an axial flow pump, the inlet and outlet blood paths align parallel to the axis of rotation or the impeller’s centerline. The rotating component functions akin to a propeller in a pipe, propelling the fluid forward. Axial pumps, rotating faster and being smaller and lighter than centrifugal pumps, consume less power. Consequently, axial pumps are more appealing for easier implantation and are well-suited for pediatric use. Therefore, continuous flow pumps are preferred and a superior choice over pulsatile pumps.

The pump impeller for continuous blood flow is primarily used in medical devices to aid or replace the pumping action of the heart. It’s an integral part of Ventricular Assist Devices (VADs) and artificial hearts, contributing to maintain sufficient blood circulation while awaiting a heart transplant or supporting individuals with severe heart failure. The impeller’s precise rotation facilitates the continuous circulation of blood, which is vital for patients relying on these devices for their cardiac health.

The applications of this type of impeller are diverse. Apart from providing circulatory support to patients with heart failure or other cardiac conditions and assisting the cardiac function of Ventricular Assist Devices (VADs), it is also used to assist surgeries during cardiopulmonary bypass, support research and development in fluid dynamics, and drive innovation in medical device technology. The design and performance of the impeller are continuously improved to enhance the overall efficiency and safety of blood pumps, contributing to advancements in medical technology. In summary, the impeller in an axial flow blood pump is a vital component with applications ranging from circulatory support to medical device innovation.

The choice of material for the impeller is crucial to ensure biocompatibility and durability. High-quality materials are selected to minimize damage to blood components and ensure the impeller’s long-term safe and effective use within the human body. The size of the impeller is designed to fit the specific medical device requirements, allowing for optimal blood flow dynamics.

The pump impeller is commonly constructed from high-quality materials such as biocompatible metals or alloys, ensuring compatibility with the human body. Stainless steel, titanium, or specialized polymers are often used due to their durability and biocompatibility. In terms of size, impellers vary depending on the specific medical device and patient requirements. In Manners Technology, they are meticulously designed and manufactured to suit various device sizes and patient needs.

Efforts are underway in academic institutions and industry to increase their usage life, make them more biocompatible, improve their performance and reliability to the level of using them as a permanent implant. At the meantime, the manufacturing of the pump impeller involves precise engineering and high-quality materials. The process includes careful material selection, machining, and assembly to meet stringent medical standards.

Manners Technology utilizes advanced manufacturing techniques to create impellers that are efficient, durable, and safe for medical applications, which is at the forefront of manufacturing high-quality pump impellers for continuous blood flow. Using Swiss-made 7-axis longitudinal lathes, our impellers are engineered with precision, using top-tier materials to ensure optimal performance, biocompatibility, and durability. With a long history of deep involvement in the medical field, our products meet the exacting standards of the medical industry, supporting advances in healthcare and improving the lives of patients.