Learn about IO needles, essential for emergency bone marrow aspiration and infusion procedures, with insights on their applications and precise manufacturing process.

An IO needle, or intraosseous needle, comprises an outer needle tube and an inner needle core. It is an essential medical device designed for bone marrow aspiration and sample retrieval, particularly in emergency situations like cardiac arrest, trauma, and shock. With its sharp tip, the IO needle can quickly and efficiently enter the bone marrow cavity to obtain bone marrow samples or facilitate procedures such as fluid infusion and blood transfusion. The sharpness of the needle tip is crucial for a fast and accurate puncture. Manners Technology focuses on medical device manufacturing and is committed to producing IO needles that meet the highest precision standards, ensuring the sharpness of the needle tip and the reliability of surgical procedures.

▲ IO needles structure schematic

▲ IO needle

IO needles are typically used in first aid and emergency situations. Their primary application is to puncture the bone marrow cavity to obtain bone marrow samples or perform therapeutic operations such as infusion and blood transfusion. The sharp needle tip design ensures that the puncture operation is quick and accurate.

IO needles are mainly used in emergency medical situations, such as cardiopulmonary resuscitation, trauma, and shock, to ensure rapid access for required treatments. In pediatric emergencies, where traditional intravenous access may be more challenging to establish due to the smaller blood vessels of infants and young children, the IO needle can provide treatment quickly and effectively. Additionally, the IO needle can be used for bone marrow puncture to obtain samples for pathological examination. For instance, leukemia patients undergoing chemotherapy can receive chemotherapy drugs through an IO needle. In special cases, such as severe edema or hemangioma, where traditional intravenous access is difficult, the IO needle offers a way to quickly obtain treatment access in these complex situations.

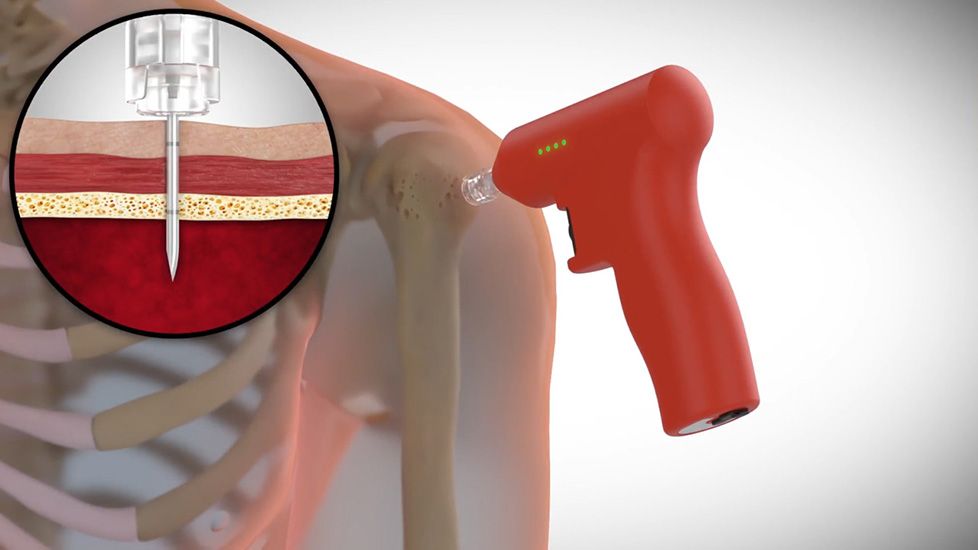

▲ IO needles application diagram

Given the critical role of IO needles in first aid, their manufacturing needs to meet highly precise standards to ensure the sharpness of the needle tip and operational reliability. Manners Technology is dedicated to manufacturing medical devices that are high-quality, safe, and reliable. We use advanced processing technology and quality control processes to ensure that each IO needle meets the strict standards of the medical industry to support emergency medical care needs.

The IO needle is a highly precise puncture device widely used in medical practice. Its manufacturing process involves multiple critical steps to ensure the product's accuracy, durability, and safety. First, medical-grade stainless steel is selected as the main material, ensuring that the IO needles have sufficient hardness and corrosion resistance when penetrating bones. Using computer-aided design (CAD) software, engineers develop the detailed geometry of the IO needles, including key parameters such as length, diameter, and angle. This is followed by a high-precision cutting process, often using laser cutting technology, to ensure the accuracy of the IO needle’s tip and overall shape.

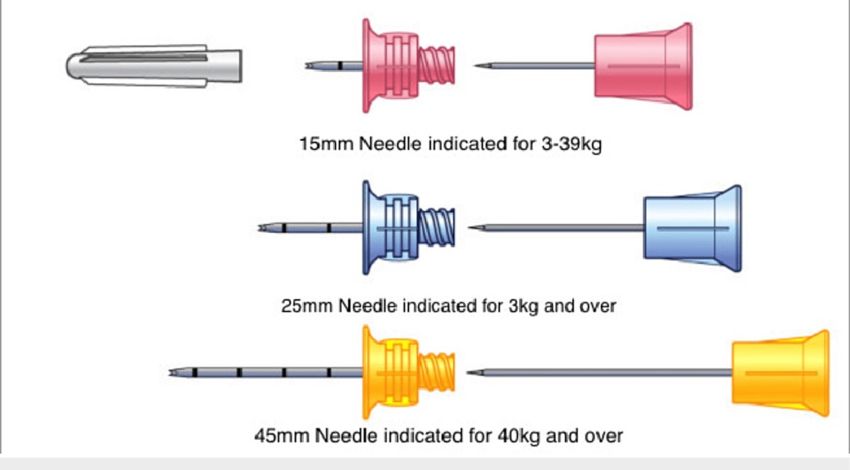

▲ IO needles size schematic

A crucial step is special processing, which includes improving sharpness and enhancing corrosion resistance. Through a professional grinding process, the tip of the IO needle is optimized for sharpness to penetrate hard tissue more easily. Mechanical or chemical polishing ensures that the surface of the IO needle is smoother, reducing friction on the tissue.

Additionally, based on customer needs, Manners Technology uses advanced laser marking technology during the manufacturing process to create clearly visible scale marks on the surface of the product. This special calibration design helps doctors accurately judge the depth of puncture during actual operations, providing reliable guidance to ensure the safety and accuracy of the procedure. Finally, assembly is a critical part of the entire manufacturing process, involving the proper fitting of the inner and outer tubes and other components to ensure the integrity and functionality of the IO needles.

▲ Laser marking on IO needles

Manners Technology is committed to producing high-quality, high-precision IO needles through its precise manufacturing process and professional team. These precise and reliable products play a key role in the medical field, providing doctors with safe and efficient puncture tools.