Understand the significance of healing abutments in dental implants. These elements aid in the healing of soft tissue and guarantee the best aesthetic outcomes for final restorations.

Healing abutments, or transgingival abutments, connect the implant fixture to the oral environment, guiding soft tissue healing and shaping before final restoration. Made from biocompatible materials like titanium or zirconia, they prevent debris entry and protect the implant site. With precise design and various sizes, they ensure optimal soft tissue management. At Manners, our advanced manufacturing ensures high-quality, customized healing abutments tailored to clinical needs, supporting seamless integration and long-term success.

▲ Healing Abutments in Clinical Use

Healing abutments, or transgingival abutments, are essential components in dental implant procedures, serving as temporary fixtures placed on the implant after its insertion. Their primary function is to guide soft tissue healing and shape the gingiva to prepare it for the final prosthetic restoration. Made from biocompatible materials like titanium or zirconia, healing abutments not only ensure a stable and aesthetic soft tissue contour but also protect the implant site from debris and bacterial contamination.

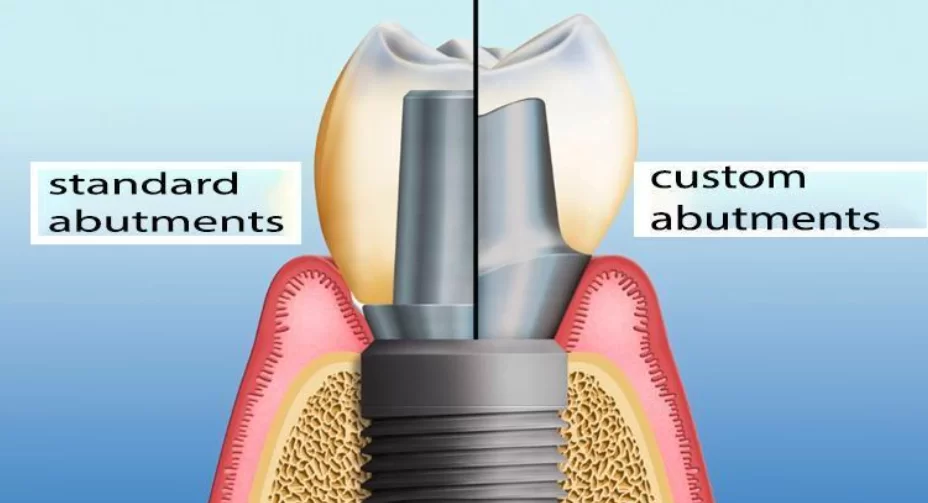

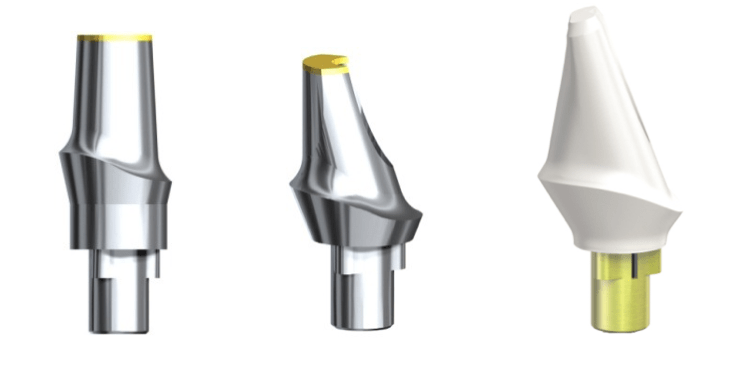

Healing abutments can be classified by various criteria. By shape, they may be cylindrical or contoured to accommodate different gingival profiles and promote natural aesthetics. By size, they come in diverse diameters and heights to fit specific implant systems and patient anatomies. Additionally, they can be standard or customized to address unique anatomical or prosthetic needs.

▲ Standard and Customized Healing Abutments

During the osseointegration period, healing abutments fulfill several crucial roles. They shape soft tissue to create a natural emergence profile for the final prosthetic crown or bridge. Acting as a protective barrier, they prevent foreign materials like food particles or plaque from entering the implant site, reducing the risk of infection. By maintaining the tissue contour, they simplify the process of prosthetic placement, ensuring a precise and secure fit.

At Manners, we excel in manufacturing high-precision healing abutments tailored to diverse clinical requirements. Our customizable designs, materials, and dimensions empower dental professionals to achieve predictable, aesthetic outcomes, supporting long-term success in implant procedures.

▲ Healing Abutments Tailored by Manners Technology

The precision manufacturing of healing abutments is an intricate process designed to ensure that these components meet the dual demands of functionality and aesthetics in dental implantology. Healing abutments play a critical role in guiding gingival healing and shaping the soft tissue profile around implants. To achieve their purpose, their design and production require advanced engineering techniques and strict quality controls.

▲ Advanced Manufacturing Equipment

The process begins with the selection of high-performance materials. Titanium, known for its superior strength and biocompatibility, is the primary choice for most healing abutments. Its strength makes it ideal for ensuring the longevity and stability of the abutment. Zirconia, on the other hand, is preferred in anterior applications for its aesthetic tooth-like appearance, while PEEK serves as an excellent material for temporary healing abutments due to its lightweight and corrosion-resistant properties.

▲ Healing Abutment Materials

The manufacturing process then moves to the shaping of the healing abutment. Using advanced multi-axis longitudinal lathes, including five-axis systems, the abutments are precision-machined to micrometer tolerances. This process allows for the creation of highly detailed geometries, such as the contoured designs that facilitate natural gingival shaping. Lathe machining ensures consistency in abutment dimensions, which is vital for compatibility with a wide range of implant systems.

Healing abutments often feature specific design elements, such as varying diameters and heights, to accommodate diverse patient anatomies. These dimensions are meticulously crafted during the machining phase to meet clinical requirements. At Manners, our expertise in precision engineering allows us to manufacture healing abutments that meet diverse clinical needs while ensuring superior performance and reliability.

To maintain the highest standards, quality control is integrated at every stage of production. High-precision instruments, such as coordinate measuring machines (CMMs) and laser scanners, verify the dimensions and tolerances of each abutment. These inspections ensure compatibility with implant systems and confirm the integrity of the design. At Manners, rigorous quality assurance protocols guarantee that each healing abutment not only meets but exceeds industry standards, delivering optimal performance and reliability in clinical applications. Through meticulous craftsmanship and rigorous quality control, we deliver components that set the benchmark for excellence in dental implant manufacturing.