Discover high-precision CNC machining for custom dental implant abutments. Manners Technology ensures ±0.001mm accuracy with advanced Swiss-type CNC machines.

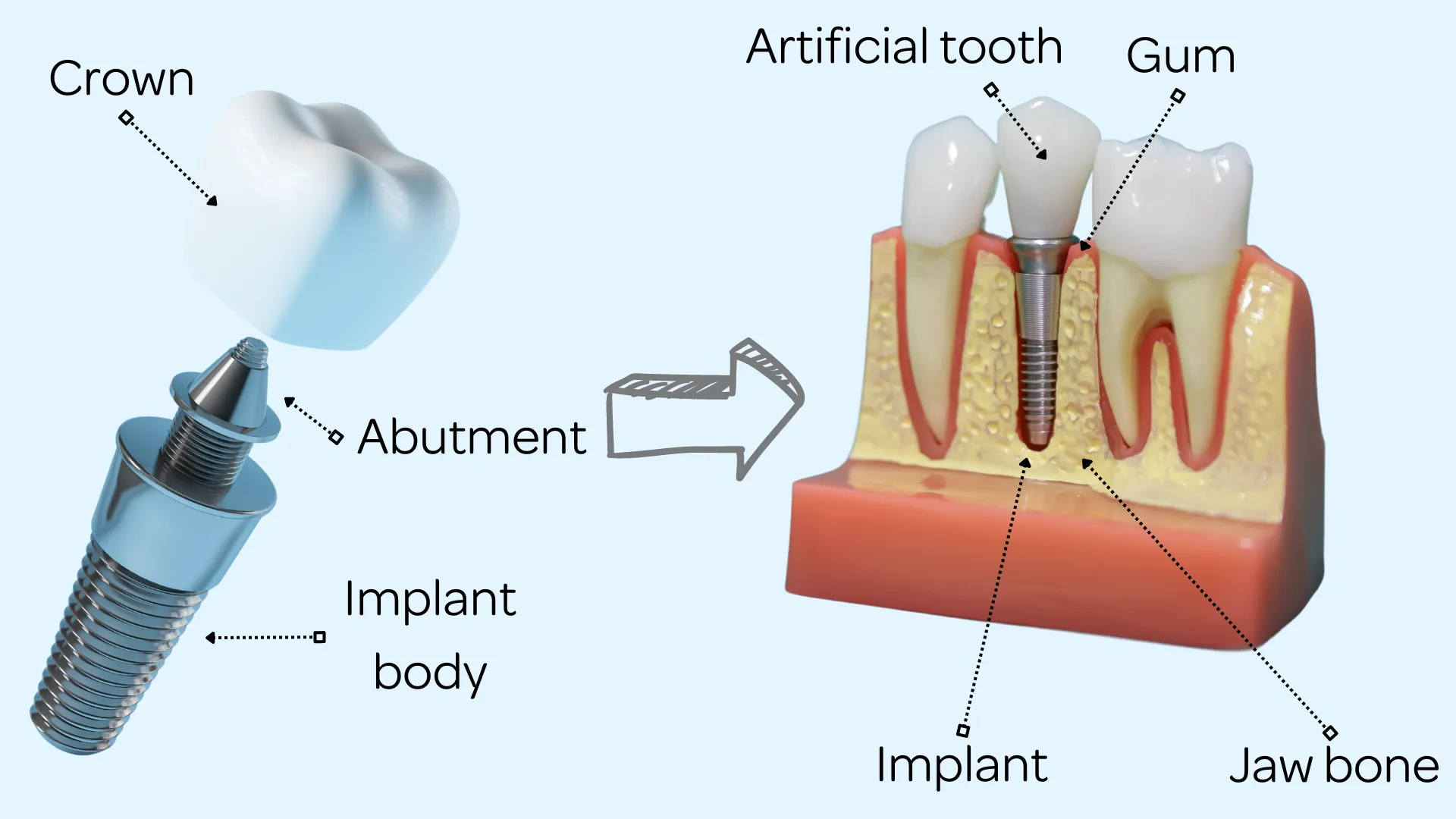

An implant abutment is a key component of a dental implant system, connecting the implant in the jawbone to the prosthetic tooth (crown, bridge, or denture). It provides support, retention, and stability while also aiding in positioning and preventing rotation. The abutment plays a crucial role in shaping the surrounding soft and hard tissues, impacting both the implant’s longevity and the final restoration’s aesthetics. Choosing the right abutment enhances implant success and improves overall treatment outcomes.

The dental implant abutment acts as the foundation for the artificial tooth, ensuring stability and proper alignment. It plays a crucial role in transferring the chewing force from the prosthetic to the implant and ultimately to the bone, promoting long-term durability.

Implant abutments require high precision and durability to ensure a perfect fit, preventing issues like misalignment, loosening, or implant failure. However, standard abutments may not always meet individual patient needs, leading to a growing demand for custom abutments.

Custom implant abutments are tailored to a patient’s unique implant position, gum shape, and missing tooth space, designed collaboratively by dentists and technicians. Common materials include titanium alloys and zirconia, making them a preferred choice for aesthetic restorations. Using advanced computer imaging and CNC precision machining, these abutments on dental are crafted with exceptional accuracy, biocompatibility, and mechanical strength.

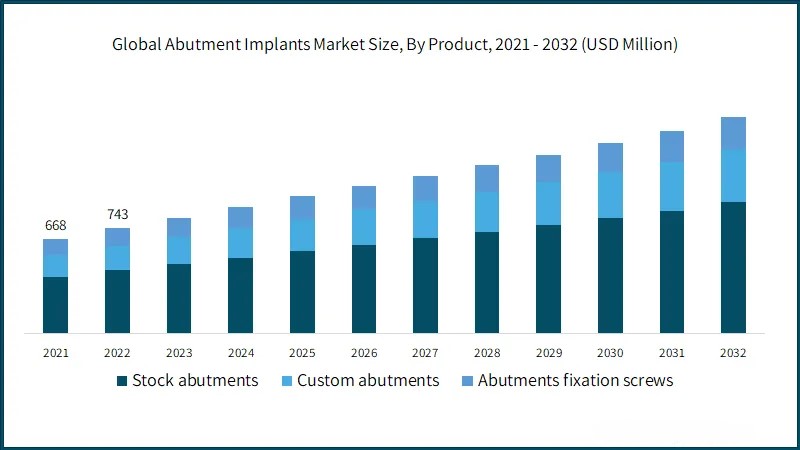

The demand for implant abutments is rising globally, driven by an aging population, increased awareness of dental health and aesthetics, and advancements in implant technology that make procedures more accessible and affordable. For instance, the broader dental implants market—which includes abutments for implant—was valued at approximately USD 4.42 billion in 2023 and is expected to reach USD 5.88 billion by 2029, growing at a CAGR of 4.85%。

Furthermore, the United Nations projects that the global population aged 65 and older will hit around 1.5 billion by 2050, a demographic shift that is significantly increasing the need for dental prosthetics, including implant abutments.

Recent data also shows that about 12.9% of dental implant procedures are performed on patients aged 65–74, highlighting the impact of an aging demographic on the field.

Additionally, technological advances—such as the adoption of 3D imaging and CAD/CAM systems—have streamlined implant procedures, reducing costs and increasing accessibility for a broader patient base, as evidenced by strong growth in key markets like Asia-Pacific.

Precision standards for implant abutments vary by region. In the USA and Germany, the required tolerance is as tight as ±0.001mm, while Japan and South Korea typically allow ±0.002mm. In contrast, China currently operates at a tolerance of ±0.005mm, though advancements in CNC technology are steadily enhancing its precision.

Moreover, the CNC machines employed in these regions differ significantly. In the USA, manufacturers often use high-precision machining centers such as the Haas VF series and DMG Mori DMU series, which are renowned for their reliability and ability to maintain ultra-tight tolerances. Germany similarly relies on advanced systems from DMG Mori and Hermle, both of which are celebrated for their exceptional precision and consistent performance.

In Japan, the emphasis on precision is reflected in the widespread use of Citizen Cincom Swiss-type CNC machines and Yamazaki Mazak centers, which typically achieve tolerances around ±0.002mm. South Korea employs sophisticated systems from Doosan and Hyundai Wia to meet its precision requirements.

Why high-precision CNC machining is crucial for international markets goes beyond meeting regulatory standards—it directly influences clinical outcomes. Ultra-precise machining, achieving tolerances as tight as ±0.001mm, minimizes micro-gaps between the abutment and the implant, which is critical for load distribution and reducing micro-movement.

For example, studies have shown that even a deviation of 0.002mm can significantly increase the risk of micro-motion, potentially leading to bone resorption and a reduction in implant survival rates. In fact, clinical data indicate that implants produced with tolerances around ±0.001mm can maintain survival rates above 98% over a 10-year period, whereas those with tolerances exceeding ±0.002mm may see survival rates drop below 95%.

This precision not only enhances product quality and implant longevity but also reduces the risk of misalignment and related complications—making it essential for manufacturers targeting high-standard international markets.

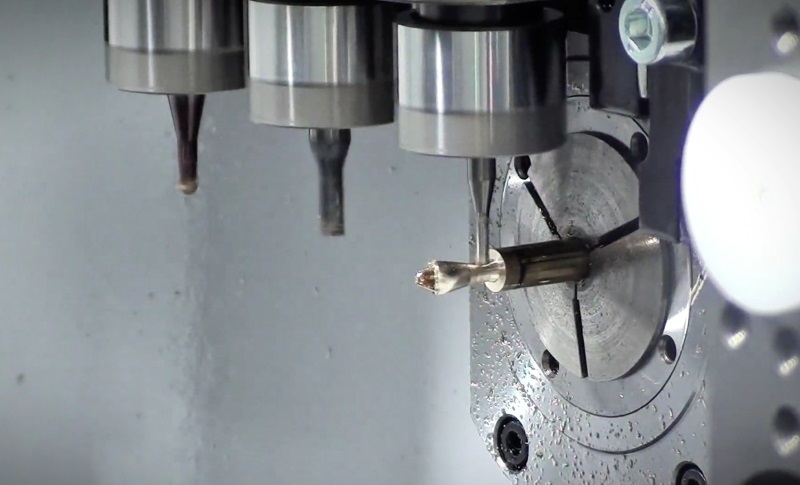

Our process begins with selecting high-performance materials—medical-grade Titanium (Ti-6Al-4V) and Stainless Steel 316L—to ensure excellent biocompatibility and mechanical strength.

For demonstration purposes, the video uses copper material.

We then use advanced Citizen Cincom Swiss-Type CNC Machines (CITIZEN L20 IX) for turning and milling, which deliver unmatched precision in small, complex parts while minimizing material waste. Our multi-axis machining further refines accuracy to a tolerance of ±0.001mm, eliminating secondary operations and boosting efficiency. Precision micro-drilling and advanced threading techniques are employed to secure an optimal fit with implant screws, thereby enhancing long-term stability and reducing the risk of loosening.

Our cutting-edge CNC technology uses Citizen Cincom Swiss-Type machines to deliver ultra-precision machining that eliminates secondary operations through advanced multi-axis capabilities, adeptly handling micro-scale features for intricate implant designs. With a tolerance of ±0.001mm—well beyond industry standards—our process is rigorously controlled by automated optical and CMM inspections and adheres to ISO 13485-certified manufacturing practices.

Additionally, our 24/7 automated machining ensures high production efficiency and cost-effectiveness by reducing material waste and offering flexible customization for various implant systems, meeting diverse dental application needs.

Feature | CNC Machining | Traditional Machining |

Precision | ±0.001mm | ±0.01mm |

Efficiency | High-speed, automated | Manual & slow |

Customization | Easy design modifications | Limited flexibility |

Cost | Lower in large-scale production | Higher labor costs |

Choosing a trusted manufacturer for custom implant abutments is critical to ensuring high-quality, precision-engineered products. Manners Technology’s use of Citizen Cincom Swiss-Type CNC Machines, adherence to ISO 13485 standards, and commitment to ±0.001mm precision make us the ideal partner for your implant abutment needs. Contact us today to learn how our advanced CNC machining services can support your business.