Discover the precision and versatility of Scorpion Needles in surgical procedures. Learn about their applications and meticulous manufacturing by Manners Technology.

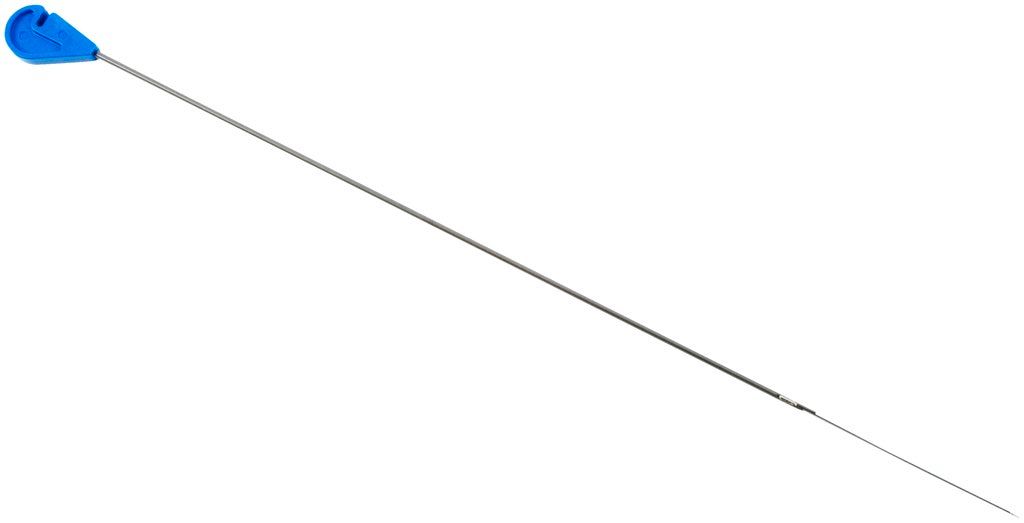

The Scorpion Needle stands as a pinnacle in surgical precision, indispensable in modern medical procedures. Comprising two primary components—the inner needle and the outer tube—it exemplifies meticulous engineering tailored for intricate suturing tasks, particularly in minimally invasive surgeries. Manners Technology, renowned for its precision engineering, has cemented its position as a leading supplier in the medical realm through the fabrication and processing of Scorpion Needles.

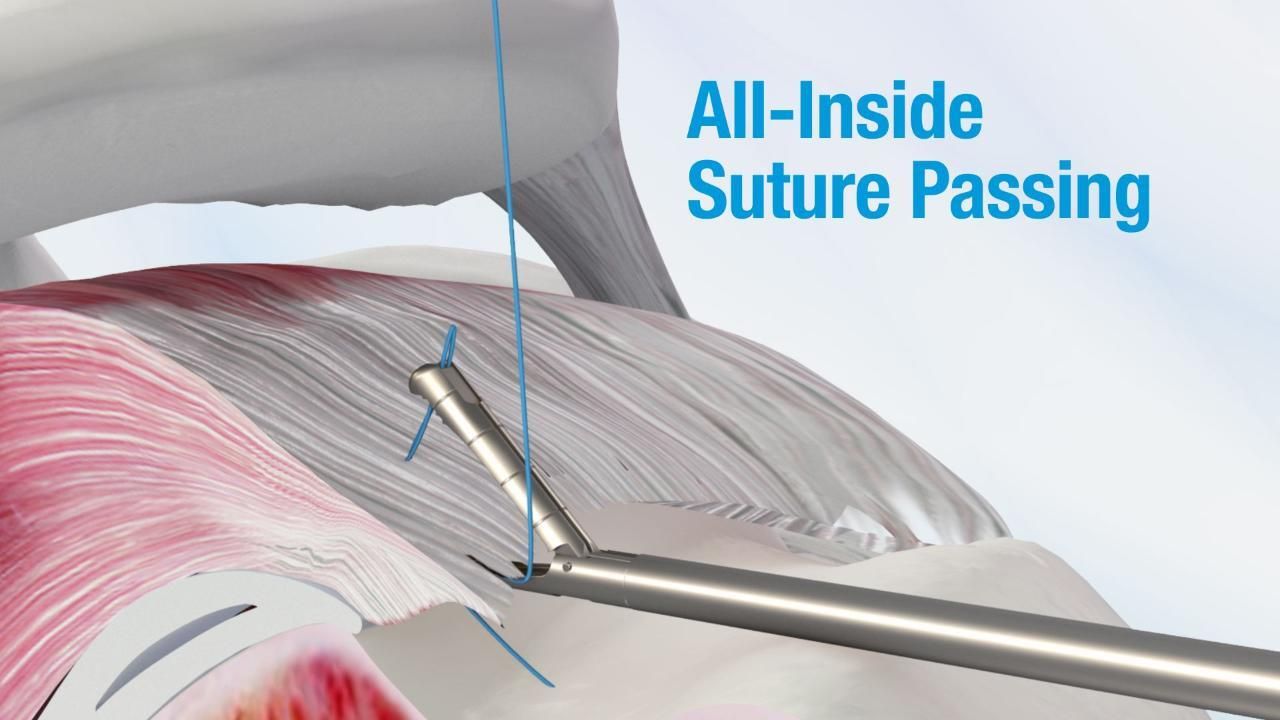

Scorpion Needles find extensive utility across a spectrum of surgical procedures, notably in disciplines demanding finesse such as neurosurgery, ophthalmology, pediatrics, and laparoscopy. Their design facilitates meticulous control and precise suturing, especially in navigating confined anatomical spaces. The synergy between the inner needle's curve and the outer tube's guidance enables unparalleled flexibility during operations.

The Scorpion Needle's precision is paramount in delicate eye surgeries like cataract procedures. Similarly, its finesse proves invaluable in intricate neurosurgical interventions. Moreover, owing to its compact size and curved design, it seamlessly integrates into minimally invasive surgeries, aiding in tissue manipulation and transection. In laparoscopy and endoscopy, the Scorpion Needle's flexibility empowers surgeons to execute precise maneuvers in constrained surgical domains, mitigating tissue interference.

Manners Technology upholds rigorous standards in material selection and manufacturing processes to ensure the excellence and longevity of its medical devices. Employing cutting-edge CNC machining, five-axis lathes, and laser cutting equipment, the company ensures adherence to exacting precision standards. This not only enhances production efficiency but also guarantees product uniformity and stability.

The manufacturing process commences with precision cutting to ensure consistency in shape, particularly focusing on the curvature between the needle tip and handle. Advanced processing techniques, including precision CNC machining and specialized needle tip treatments, are employed to refine the inner needle, ensuring optimal sharpness and smoothness crucial for tissue penetration.

Stringent quality management protocols oversee every stage, from material inspection to final product acceptance. With a dedicated technical team and adaptable manufacturing capabilities, Manners Technology delivers tailor-made Scorpion Needles, catering to diverse surgical exigencies with unwavering precision and reliability.