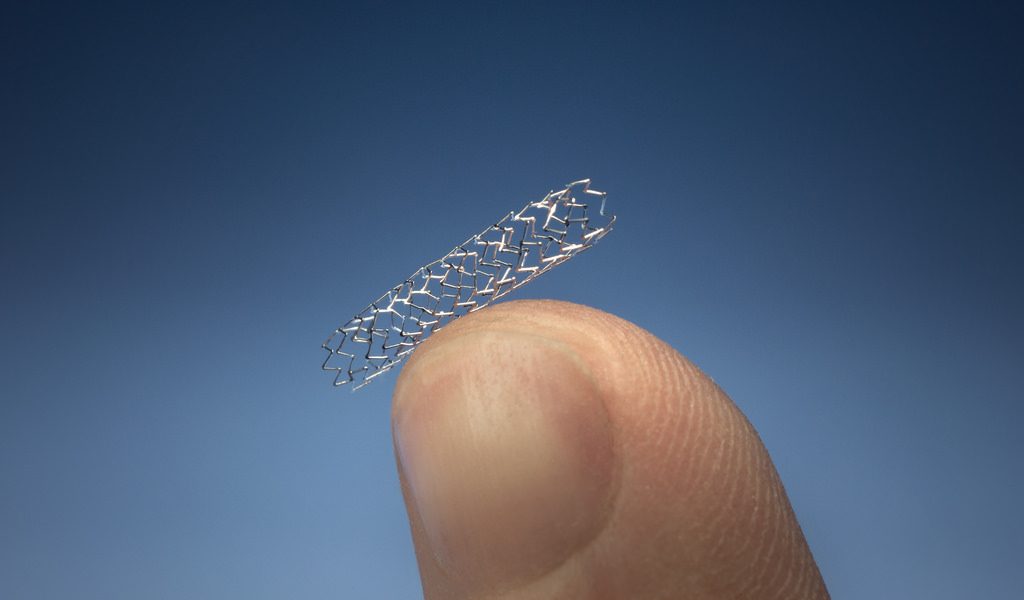

1. What are Trocars?

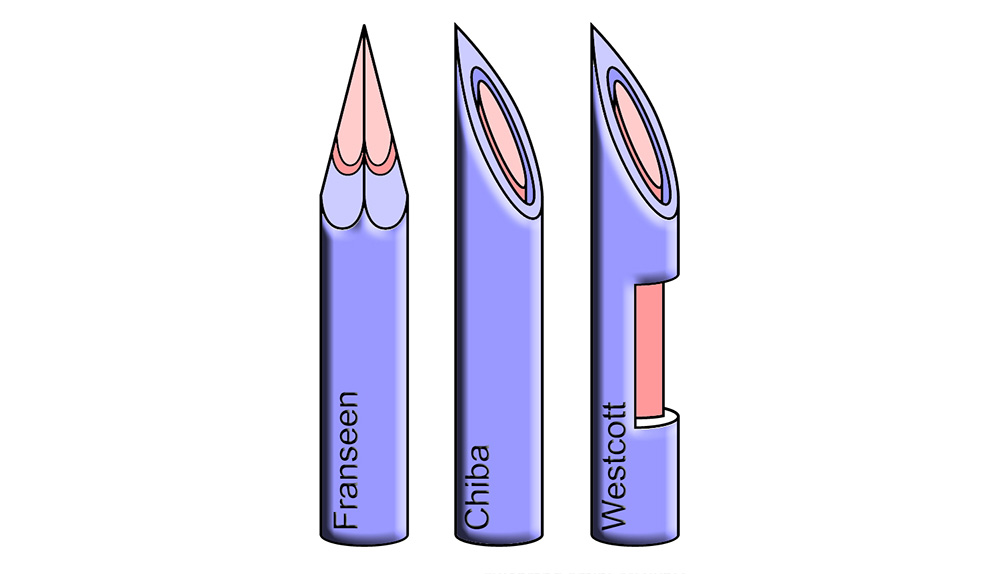

The Trocar, a surgical instrument also known as “disposable trocar”, “laparoscopic trocar” or “trocar and cannula”, consists of three parts: an awl with a sharp-pointed tip to make small skin incisions, a hollow cannula to reach the body cavity and a seal at the top of the cannula. Manners Technology is proficient in producing this versatile, specialized surgical device that proves useful in a variety of procedures. Its application in laparoscopic procedures and other minimally invasive surgery (MIS) can improve successful catheter insertion, minimal pain and discomfort of patients, faster recovery times, and better security.

2. Applications

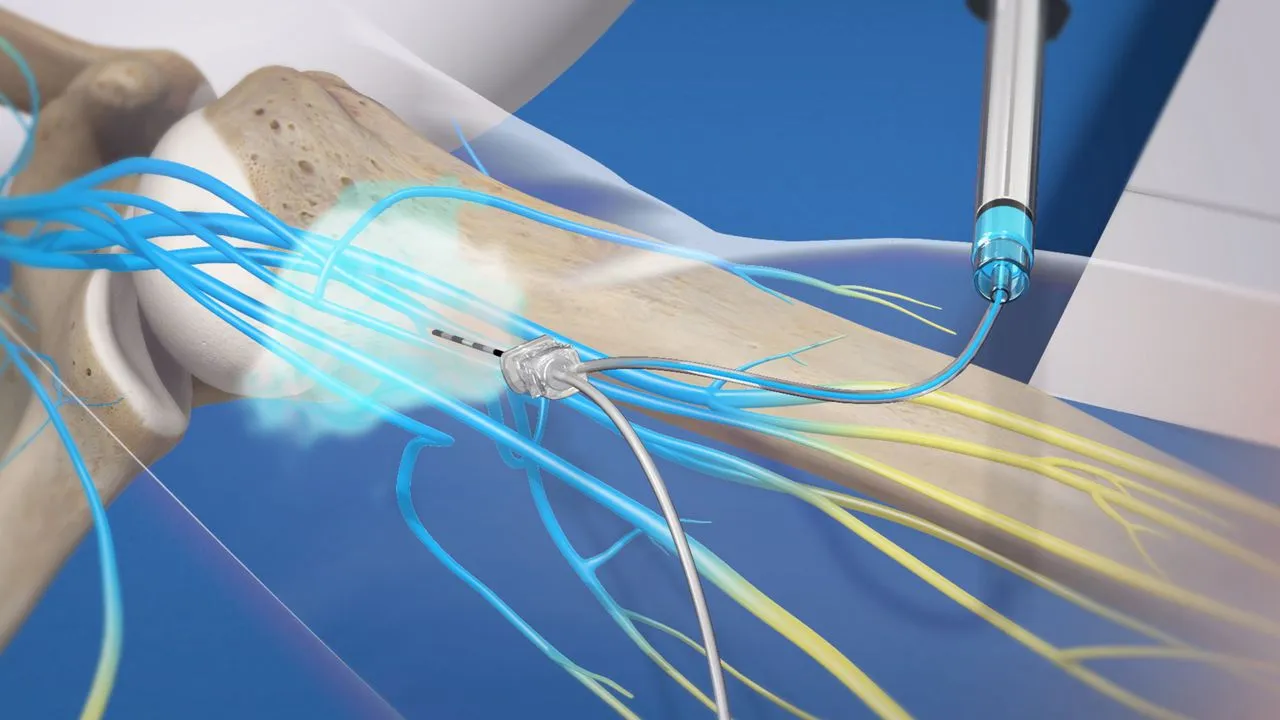

Generally, a comprehensive range of ergonomically designed trocars can serve as endoscopic approaches to gynecologic disease, and can also be applied in laparoscopic gastric bypass, laparoscopic inguinal hernia repair, right and left colectomy with open and laparoscopic ways, wrist arthroscopy, laparoscopic duodenal switch and sleeve gastrectomy procedures, robotic versus standard laparoscopic prostatectomy, and other laparoscopic surgeries or robotic surgeries.

Thereinto, as a tool of diagnosis to assess the progress of treatment and the staging of diseases, abdominal laparoscopic surgery has become the iconic application of the trocar. The laparoscopic trocar is able to be utilized to examine appendix, bowel (both small intestine and large intestine), gallbladder, liver, pancreas, pelvic cavity, female reproductive organs, and etc. When removing gallstones, fibromas, and benign and cancerous tumors of most kinds, laparoscopy also allows for a small incision, minimal time under anesthesia, fast recovery.

Another popular application of the trocar is the insertion of slow-release hormone pellets for treatment of male and female endocrine disorders. Use of a modern trocar allows insertion of the hormone through the smallest possible incision which reduces trauma to the skin.

Without needing to stitch the fascia binding tissue beneath the skin, Manners Technology’s puncture device allows incision widths of no more than 5 mm to allow for insertion of pellets and reduce the already-small risk of hernia even further.

3. Material Options

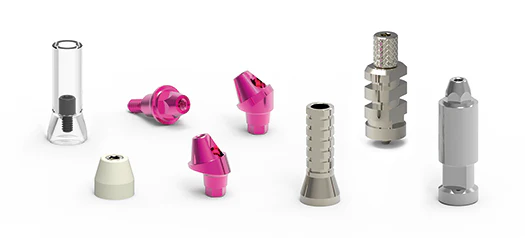

The disposable trocar is made of stainless steel material for cannula and plastic material for awl and seal. According to different surgery needs, there are several materials for choice: 304, 316 L, L 605, Ni-Ti and other alloys for stainless steel part, as well as resin ABS, silicone, nylon and polycarbonate (PC) and others for plastic part.

When it comes to why these materials were chosen to make this medical-grade device, we have to mention the quality properties of these materials. Take the plastic one as an example, such as ABS: it has very good mechanical properties, dimensional stability, processing ability, chemical resistance, and a high-quality appearance. For silicone, it has electrical-insulating properties, chemical stability, and the wide temperature range over which they retain resiliency. Nylon has high wear and abrasion resistance, high tensile and compressive strength and low coefficient of friction. And polycarbonate (PC) has optical clarity, outstanding strength, stiffness, and impact resistance.

4. Manufacturing

In MIS surgery, it is necessary to switch camera angles, points of view and a variety of other tools as the operation proceeds. The distinctively engineered visual tip greatly reduces wound defect size as well as insertion force into the abdominal cavity. With direct visualization of the various tissue layers when accompanied by a laparoscope during insertion, injuries due to blind entry and a sharp blade are virtually eliminated. With bladeless optical tip and a stable platform for instrument visualization and abdominal wall retention, trocars serve as the gateways that allow minimally invasive instruments to pass.

Manners Technology uses 5-axis precision CNC machining services to process these complex metal and plastic parts. The two different material parts (stainless steel part and plastic part) are combined into a complete finished product through two plastic injection molding processes. All sterilization process will be done before assembly. Besides, packaging and each completed process needs to be cleaned before moving on to the next process.

In Manners Technology, our products are inspected for burrs, cracks, pits, machining marks and dirt. With electro polished for hygienic surfaces and packaged in segregated environment and over 6 quality inspections, Manners Technology is committed to meet exact specifications in cutting edge, point, handle, smoothness, dimension, and raw materials.