Explore top-notch Bevel Edge Cutter Dissector Blades, crafted with precision using advanced 5-axis machining, centerless grinding, and laser welding.

In surgical and clinical procedures in the medical field, precise tissue isolation and cutting is crucial. A Bevel Edge Cutter Dissector Blade usually has a smooth outer edge and a toothed or scored inner edge, giving it a bevel shape. This type of blade is commonly used in applications that require precise cutting and separation of tissue, such as surgery and anatomy. The Bevel Edge Cutter Dissector Blades allow medical professionals to perform precise tissue separation while reducing the risk of tissue damage. Medical Bevel Edge Cutter Dissector Blades, as part of Manners Technology’s medical blade series, have become the first choice of medical professionals due to their special design and exquisite manufacturing.

The design of the Bevel Edge Cutter Dissector Blades is very unique. The outer edge is usually smooth, while the inner edge is beveled. This design makes the Bevel Edge Cutter Dissector Blades very useful in medical applications where precise tissue separation is required. Their teeth or notches provide additional gripping and cutting capabilities, aiding medical professionals in delicate operations. The smooth outer edge helps prevent tissue tearing or damage, making it particularly useful when gentle cutting is required.

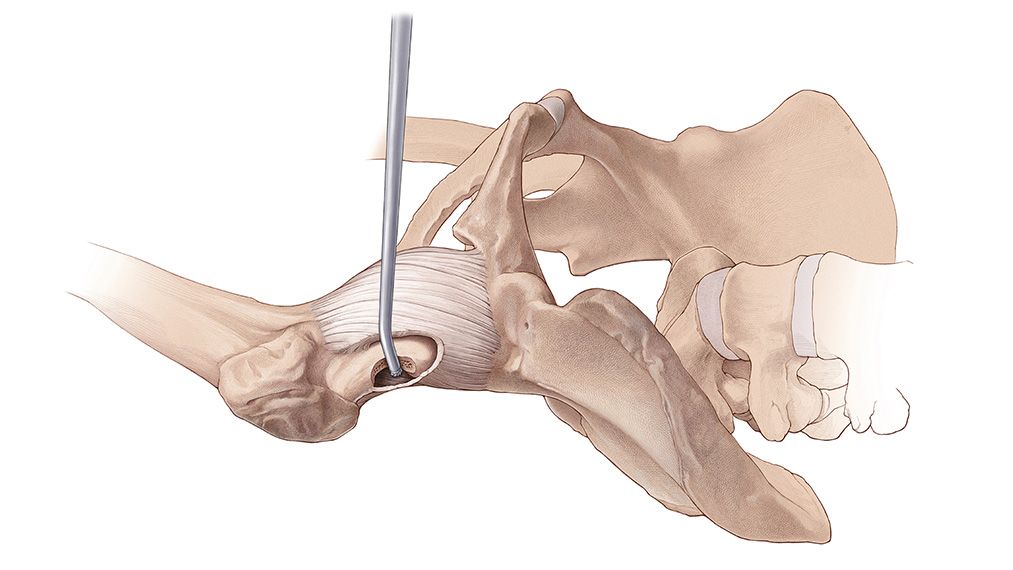

In surgical procedures, medical Bevel Edge Cutter Dissector Blades are used for tissue separation and cutting, particularly in operations that require high precision to minimize the risk of nerve damage. They play a crucial role in brain surgeries, spinal surgeries, and intraoperative tissue sampling.

In operations requiring exceptional precision, the finely designed inner blade and smooth outer blade of these Bevel Edge Cutter Dissector Blades make them an ideal choice for medical applications. Bevel Edge Cutter Dissector Blades are instrumental in ocular surgeries, lens surgeries, and other ophthalmic procedures. Ophthalmic surgeries require highly accurate manipulation of the visual system. They can be used for cutting ocular tissues, corneal surgeries, and iris operations, ensuring the accuracy of procedures and minimizing tissue damage.

Microsurgical procedures also require highly precise tools for operations at the level of tiny tissues and cells. Bevel Edge Cutter Dissector Shaver Blades play a critical role in microsurgical procedures, assisting healthcare professionals in achieving highly refined operations. These blades are often utilized for tissue separation, specimen dissection, and laboratory research. Their fine cutting capabilities contribute to obtaining high-quality anatomical samples for detailed tissue structure studies.

As a leading manufacturer in the field of medical blade production, Manners Technology takes pride in producing high-quality Bevel Edge Cutter Dissectors Blades. Our blades undergo precise manufacturing to ensure sharpness, precision, and flawlessness. Whether used in surgical procedures, anatomical operations, or other specialized fine procedures, Manners Technology’s Bevel Edge Cutter Dissectors Shaver Blades serve as a reliable companion for medical professionals.

The manufacturing process of medical Bevel Edge Cutter Dissectors Blades is a highly complex engineering endeavor, requiring precision and sharpness to meet the demands of medical applications. Manners Technology is dedicated to ensuring that each Cutter Dissector Blade meets the highest standards. The initial step in the manufacturing process involves precise cutting using a five-axis longitudinal lathe to shape the overall structure of the blade. The accuracy of this step is crucial to ensure the precision and consistency of the blade.

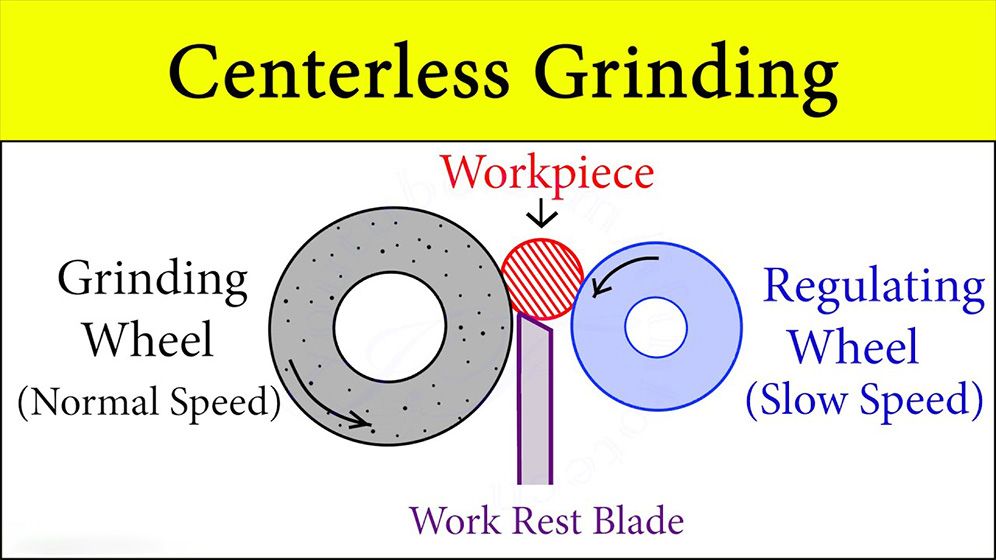

Subsequently, the blade head undergoes a hardening process using 17-4 alloy steel, a material known for its exceptional durability and rigidity. The hardness value of our blades can reach HRC 52-56, enhancing the wear resistance and cutting performance of the blade head. Further milling of the blade head ensures the sharpness and smoothness of its cutting edges, optimizing the blade for the best cutting performance. The entire blade undergoes centerless grinding to guarantee surface smoothness and precision, reducing friction and resistance during the cutting process and enhancing cutting efficiency.

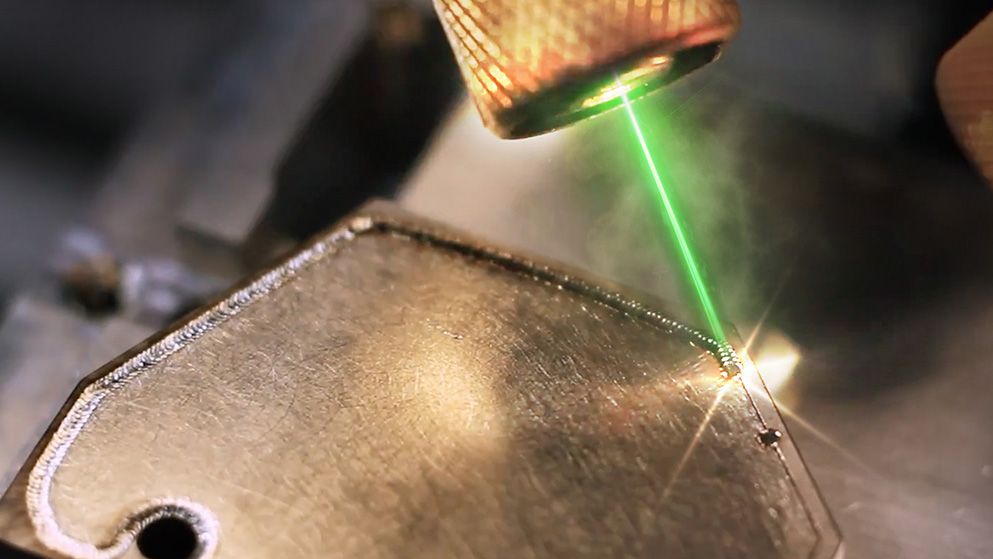

Finally, the blade head and body are securely joined through laser welding, ensuring the precise alignment of the blade head and body for outstanding performance during operations. These manufacturing steps reflect Manners Technology’s commitment to blade quality, ensuring each Bevel Edge Cutter Dissector Blade possesses exceptional cutting capability and durability.

Manufacturing high-quality Bevel Edge Cutter Dissector Shaver Blades requires strict processes and quality control. The medical Bevel Edge Cutter Dissector Blades from Manners Technology are precision manufactured to ensure that both the inner edge teeth or indentations and the smoothness of the outer edge of the blade meet high standards. Our products undergo multiple quality inspections to ensure each blade meets the requirements of medical applications.