Learn about Full Radius Blades used in medical procedures for precise, curved cuts in surgeries like ophthalmology and neurosurgery.

A Full Radius Blade, also known as a “Full-circle Plane” or “Full Radius Curve Plane,” is a cutting tool used in medical procedures to cut tissue, organs, and other biological materials. This blade has a fully rounded edge, unlike the straight or curved edges of traditional blades. Its full-circle shape is particularly useful for surgeries requiring curved or arc-shaped cuts, such as cutting the cornea in eye surgery or processing brain tissue in neurosurgery. Manners Technology produces Full Radius Blades capable of making very smooth and precise curved cuts, which is essential for surgical procedures that require precise control.

The medical Full Radius Blade is a widely used surgical tool known for its unique features and benefits. Its full-circle shape makes it ideal for procedures requiring curved cuts. For example:

Eye Surgery: Precise corneal cuts are necessary to accommodate a new transplanted cornea. The Full Radius Blade ensures that the incisions conform to the curvature of the eyeball for a successful procedure.

Neurosurgery: Precise cuts of brain tissue are required, and the Full Radius Blade provides highly precise cutting and control with minimal effort.

Microsurgery: Tiny, complex operations benefit from the precise cutting capabilities of the Full Radius Blade.

Medical professionals favor the Full Radius Blade for its ability to produce very smooth incisions, reducing tissue damage and healing time at the incision edges, which is important for postoperative recovery. Additionally, the Full Radius Blade reduces trauma to surrounding tissue during surgeries, lowering the risk of infection and complications.

Overall, the Full Radius Blade is a versatile surgical tool, valued for its full-circle shape, precise cutting, smooth incisions, and reduced trauma. It is used in various types of surgeries, including ophthalmic surgery, neurosurgery, microsurgery, plastic surgery, skin cutting, soft tissue cutting, dental surgery, and endoscopic surgery. Manners Technology specializes in producing Full Radius Blades that not only improve the effectiveness of surgery but also promote patient recovery, making them an indispensable part of surgical care.

As a highly specialized tool, Full Radius Blades require high manufacturing precision and quality control to meet the medical industry's standards. They are usually made of stainless steel or other biocompatible materials that are highly corrosion-resistant and biocompatible to ensure safety and reliability in clinical applications.

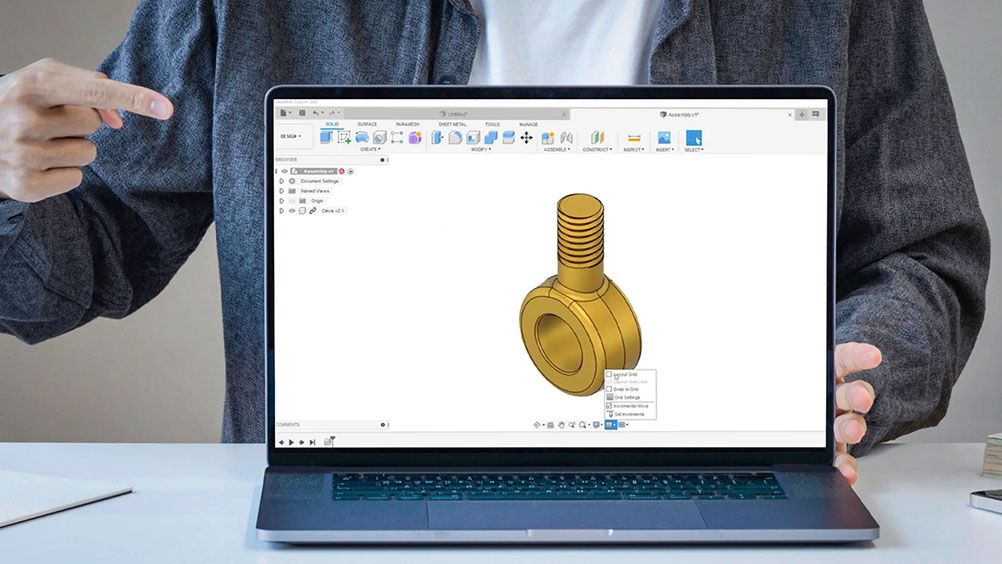

The design process typically begins with computer-aided design (CAD). Design engineers use CAD software to create accurate models of Full Radius Blades, including edge shape and geometric parameters. The manufacturing process often involves CNC machines capable of cutting, grinding, and shaping metal materials with high precision to create the blade’s shape and geometry.

Manners Technology also heat-treats the blades to increase their hardness and wear resistance. For example, 17-4 stainless steel is used for hardening treatment to improve its strength and hardness, nearly reaching HRC 52-56. This includes quenching, tempering, and other heat treatment processes to ensure the blade achieves the required performance.

During the manufacturing process, blades undergo precision grinding and polishing to ensure their edges are extremely sharp and smooth. After machining is complete, Manners Technology performs exacting quality control, using measuring tools and inspecting the geometry shapes, blade angles, and cutting edges to ensure the blades meet customer specifications and standards.