Explore the precision and versatility of Oval and Round Burs in medical shaver blades, vital tools in orthopedic surgeries for effective tissue and bone removal.

Medical Blades, which are also called “Medical Shaver Blade”, “Resector Cutter”, “Grinding Bur”, introduces a revolutionary leap in surgical instrumentation with the Oval Bur and the versatile Spherical Bur, also known as Round Bur or Dome Drill. These state-of-the-art tools are poised to redefine orthopedic surgery, delivering unmatched precision and efficiency.

In the complex world of medical procedures, Oval Burs and Round Burs stand as indispensable tools, blending precision with versatility. Whether delicately sculpting bone or efficiently removing tissue, these tools represent the convergence of tradition and innovation. In the realm of medical procedures and interventions, precision and effectiveness are paramount. Among the array of tools that medical professionals rely upon, the Oval Bur and Round Bur shine as exceptional instruments that play vital roles in various medical applications. Let’s delve into the world of medical burs, exploring the distinct qualities and contributions of Oval Burs and Round Burs.

Much like their woodworking counterparts, medical Oval Burs are characterized by their narrow, elongated shape. However, in the medical context, these burs are utilized to perform intricate tasks with utmost precision. Crafted from biocompatible materials such as stainless steel or Niti alloys, Oval Burs are designed to excel in applications requiring fine detail and delicate maneuvers.

In dentistry, for instance, Oval Burs find their place in procedures like crown preparation, where they facilitate precise removal of enamel and dentin. Their slim profile enables dentists to shape teeth effectively while preserving surrounding structures. Moreover, in neurosurgery, Oval Burs aid surgeons in delicately removing bone or tissue during procedures like craniotomies, allowing for access to sensitive areas while minimizing trauma.

It represents a pinnacle of precision in surgical tools. Engineered for rapid bone resection, Manners Technology’s high-speed oval bur boasts an operating speed of up to 12,000 rpm. This remarkable tool provides surgeons with unprecedented control and efficiency in extensive bone and cartilage removal procedures, such as subacromial decompression. With its large cutting flutes, the Oval Bur ensures not only efficient resection but also minimizes tissue disruption, contributing to faster healing. Its advanced alloy construction ensures durability and longevity, making it a steadfast companion in surgical interventions where precision matters most.

The Spherical Bur, a versatile tool alternatively known as Round Bur or Dome Drill, are hailed for their versatility and adaptability across a spectrum of medical procedures. With their cylindrical shape and rounded tip, these burs are well-suited for tasks requiring efficient material removal or smoothing surfaces. Whether in orthopedics, podiatry, or dermatology, Round Burs are integral tools that cater to a wide range of needs.

Orthopedic surgeons rely on Round Burs to remove bone tissue during joint replacement surgeries or bone reshaping procedures. In podiatry, they aid in the removal of calluses or bony prominences, enhancing patient comfort and mobility. Dermatologists leverage Round Burs for precise skin lesion removal, minimizing damage to healthy tissue.

The able-to-specialty sizes round burs, designed for high-speed operation, also features an operating speed of up to 12,000 rpm. Crafted from high-impact, high-toughness stainless steel or other medical-grade materials, this blade embodies the perfect balance of durability and precision. Its ultra-sharp edge ensures meticulous osteochondral debridement and precise notchplasty procedures. Furthermore, the blade’s ultra-high anti-rust properties and exceptional wear resistance contribute to its prolonged performance and reliability.

Medical shaver blades are essential instruments used in orthopedic surgeries to address various joint-related conditions. These instruments play a crucial role in reshaping, smoothing, and removing damaged or inflamed tissues within joints. The applications of medical shaver blades involves a range of orthopedic procedures, including meniscectomy, synovectomy, ACL surgery, and subacromial decompression.

For example, meniscectomy involves the use of medical shaver blades to remove damaged or injured tissues from the meniscus of the knee joint. The primary objective is to eliminate the compromised tissue, stabilize the meniscus edges, and restore normal knee joint functionality. Synovectomy is a procedure where medical shaver blades are utilized to partially or completely remove the synovial membrane, which lines the interior of joints. This procedure is commonly employed to treat conditions such as synovitis or rheumatoid arthritis that lead to inflammation of the synovial membrane.

Within ACL surgery, medical shaver blades have two distinct applications: ACL Fragment Removal: This refers to the use of blades to remove residual fragments of a torn ACL, preparing the site for potential reconstruction surgery. ACL Reconstruction: In this procedure, medical shaver blades aid in the preparation of the bone for receiving a graft (typically from a tendon) that replaces the ruptured ACL. The aim is to restore stability to the knee joint.

Besides, subacromial decompression surgery targets impingement involving the rotator cuff tendons and the subacromial bursa beneath the shoulder blade. Medical shaver blades are employed to clear any obstructions and remove worn portions of the rotator cuff tendons, relieving compression and improving shoulder joint movement.

Medical shaver blades are versatile tools used across a spectrum of orthopedic procedures. From meniscectomy to synovectomy, ACL surgery, and subacromial decompression, Simultaneous Resection of Soft Tissue and Bone: This blade is designed to efficiently resect both soft tissue and bone using a single tool, eliminating the need for a separate burr for bone removal. This streamlines the process and reduces the number of instruments needed during the procedure. They play a vital role in reshaping damaged tissues, smoothing joint surfaces, and restoring proper joint function. Their precise applications contribute to improved patient outcomes and the successful treatment of various joint-related conditions. As one of our core products in Manners Technology, it offers special modes for facilitating intra-operation and improving surgical efficiency.

The traditional design of the medical shaver blade involves a wire-cut processing technique, which employs high-temperature carbonation for operation. This approach yields a surface texture that is notably coarse. Under a 50x magnification, evident micro serrations become apparent, signaling its limitations in achieving smoothness. Unfortunately, this design also suffers from subpar edge sharpness. The cutting process tends to generate excess heat, exacerbating the risk of inadvertently drawing tissue along with fractures. Despite these drawbacks, it’s noteworthy that this approach is relatively economical.

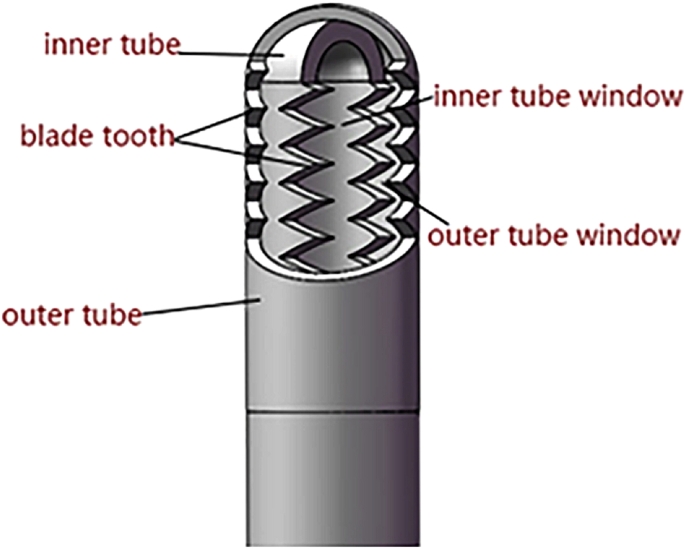

Furthermore, the traditional structure is realized through direct mold completion. However, this method gives rise to a challenge in maintaining precise clearances between the inner and outer blades. The available clearance margin spans from 0.075 to 0.110 units. Regrettably, due to the inherent limitations of mold processing, achieving a higher level of accuracy remains elusive. Consequently, this design results in a substantial gap between the inner and outer blade sections. In surgical contexts, this gap heightens the probability of unintentionally engaging with and displacing surrounding tissue during cutting. Moreover, residual materials from the mold manufacturing process may persist during surgery, introducing additional complications.

In light of these considerations, traditional medical shaver blade design carries inherent shortcomings that impact both performance and procedural outcomes.

The development of medical shaver blades has undergone significant advancements, incorporating cutting-edge technologies that enhance overall performance and durability. In modern medical Specifically designed to cater to the demands of arthroscopic procedures, these blades are essential tools for surgeons facing diverse requirements during such surgeries.

Equipped with a uniquely designed blunt-cone tip and cutting window, these blades are tailored to access confined joint spaces. This design feature enhances the surgeon’s ability to navigate and operate within narrow areas, ensuring effective targeting of the intended site while minimizing interruptions caused by blockages.

Recognizing the potential for tissue damage during insertion and removal, blade design prioritizes effective tissue contact. This accessibility aids surgeons in accurately targeting and excising tissue, thus boosting surgical efficiency. Simultaneously, it minimizes damage to surrounding structures, preserving joint integrity and reducing postoperative complications.

The blade’s intricate structure minimizes the likelihood of blockages during use, especially crucial during surgeries involving tissue excision and removal. Additionally, the generation of metal debris is significantly reduced, mitigating the risk associated with fragment-related complications and maintaining a clean surgical field.

Maintaining sharpness throughout the surgical process is a pivotal trait of these blades. This feature is essential for consistent precise cutting and efficient tissue removal without the need for frequent blade replacements. Integrating these functionalities into blade design aims to offer efficient and effective tissue excision while minimizing potential complications and instrument changes. This advancement has the potential to enhance surgical outcomes and reduce procedure durations.

The ergonomic design of these blades contributes to the comfort and control of medical professionals during procedures. Advanced manufacturing techniques, including computer-guided machining and biocompatible coatings, ensure that these blades meet the highest standards of quality, safety, and performance.

The evolution of medical shaver blade design exemplifies a commitment to optimizing arthroscopic procedures. With features such as adaptive navigation, enhanced tissue accessibility, sustained sharpness, and reduced blockage risks, these blades empower surgeons to conduct surgeries more effectively and efficiently. Through advanced manufacturing and thoughtful design, these innovations underscore the potential to elevate surgical precision while ensuring the utmost patient safety and surgical excellence.

In the realm of medical instrumentation, medical shaver blade design is undergoing a remarkable evolution. As advancements in technology and materials continue to shape the medical landscape, the future of medical shaver blades is being reimagined.

One of the most promising directions for future medical shaver blade development lies in the utilization of advanced manufacturing techniques. Manners is always committed to enhanced precision through advanced manufacturing: the cutting-edge precision technologies we utilize and introduce such as high-tech manufacturing and computer-guided machining enable the creation of intricately detailed and precisely calibrated blade designs. These techniques facilitate the production of sharper, smoother blades with reduced micro-serrations, ultimately enhancing the accuracy and effectiveness of tissue cutting.

The future of medical shaver blade design may witness the integration of optical guidance systems. Miniaturized cameras and sensors embedded in the blade could provide real-time imaging and data feedback, aiding surgeons in precise navigation within confined spaces. This innovation could elevate the precision of incisions, enhance tissue removal, and reduce the risk of inadvertent damage to surrounding structures. It is worth mentioning that the (laparoscopic) trocar produced by Manners Technology, which is used in laparoscopic procedures and other minimally invasive surgery (MIS) has equipped with optical tip for instrument visualization.

Besides, as medical practices increasingly shift towards personalized care, medical shaver blade design may follow suit. Customization based on patient anatomy and surgical requirements could lead to improved outcomes. Personalized and patient-centric design might allow for the creation of patient-specific blade designs, ensuring optimal fit and functionality for each individual. This is also precisely what Manners Technology has been striving for.

The future of medical shaver blade design is poised for revolutionary change. From advanced manufacturing techniques and even nanotechnology integration to the optical guidance systems and personalized design, these innovations hold the promise of elevating surgical precision, improving outcomes, and enhancing patient care. As medical technology continues to push boundaries, the medical shaver blade is destined to play an integral role in shaping the future of minimally invasive procedures.