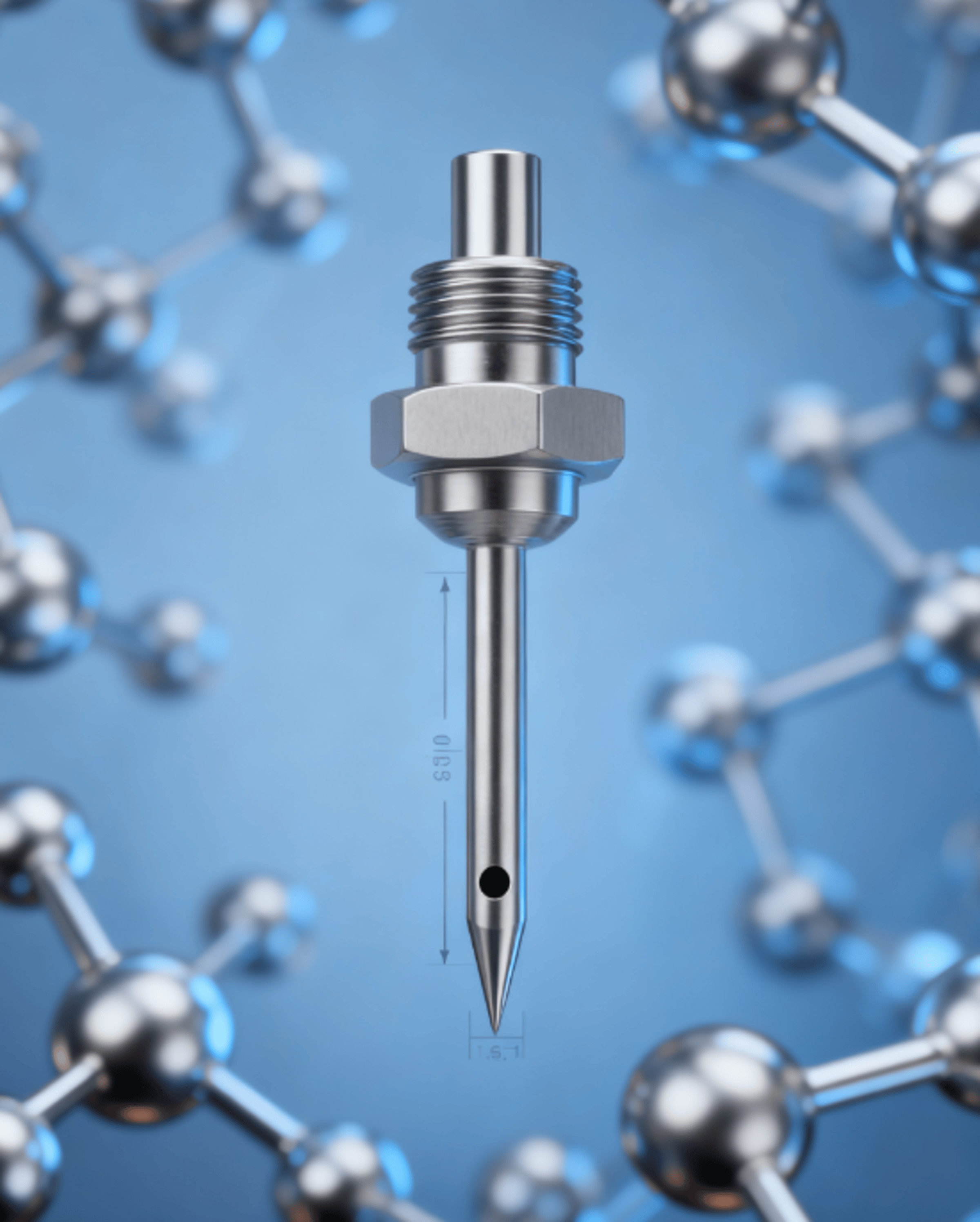

High-precision H₂O₂ transfer needle for safe hydrogen peroxide delivery—durable, corrosion-resistant, and leak-proof design.

The Hydrogen Peroxide (H₂O₂) Transfer Needle is a critical precision component used in hydrogen peroxide delivery systems. It is widely applied in medical sterilization equipment, pharmaceutical manufacturing, laboratory automation, and industrial disinfection systems.

(1) Medical Sterilization and Hospital Equipment

In low-temperature plasma sterilizers, surgical instrument disinfectors, and medical sterilization chambers, the H₂O₂ transfer needle precisely injects high-purity hydrogen peroxide into the reaction chamber, ensuring even diffusion and vaporization for effective sterilization.

Because of hydrogen peroxide’s strong oxidizing nature, ordinary metals are prone to corrosion and leakage. Therefore, 316L stainless steel is commonly used, while titanium alloy or nickel-based Inconel versions are adopted in high-end systems for superior corrosion resistance.

(2) Pharmaceutical and Laboratory Systems

In pharmaceutical production lines, GMP laboratories, and aseptic solution systems, the needle enables accurate dosing and safe transfer of hydrogen peroxide, preventing cross-contamination and residue.

Custom H₂O₂ transfer needles can be tailored for flow rate, needle length, and orifice size to ensure uniform distribution and sterilization efficiency.

(3) Food, Electronics, and Industrial Disinfection Systems

In food packaging, beverage filling, and electronics manufacturing, hydrogen peroxide is used for surface sterilization. The needle atomizes and sprays H₂O₂ evenly onto containers, pipelines, or equipment walls, ensuring a sterile and efficient production environment.

(4) Research and Special Applications

In chemical experiments, aerospace, and material aging studies, H₂O₂ transfer needles are used for precise injection of oxidizing media or to stabilize gas flow and reaction conditions.

(1) Pre-installation Check

• Ensure the needle’s thread matches the equipment port; do not force tightening.

• Use proper torque to avoid weld stress concentration.

• Keep all internal channels clean—no oil, dust, or metal debris allowed.

(2) During Operation

• Confirm all seals are tight before startup.

• Avoid impact, bending, or frequent disassembly.

• For high-concentration H₂O₂ (≥35%), install an anti-backflow system and ensure ventilation.

• Periodically inspect and rinse the tip and laser orifice with deionized water.

(3) Cleaning and Maintenance

• Flush internal channels with deionized water after each use to prevent crystallization.

• Dry naturally—avoid acidic or chlorine-based cleaners.

• Perform electropolish integrity testing every 6 months to maintain corrosion resistance.

• Store in a dry, clean, and shaded environment.

(4) Safety Guidelines

• Operators must wear gloves, goggles, and protective aprons.

• Keep away from open flames, static electricity, and heat sources.

• If skin contact occurs, rinse immediately with water.

| Failure Phenomenon | Possible Cause | Corrective Action |

| Uneven discharge or weakened spray | Laser orifice blockage, crystallized residue, or trapped air bubbles | Clean internal channels and vent the system; replace the needle if necessary |

| Leakage at the interface | Aged O-ring, loose threads, or weld crack | Replace the O-ring or needle; inspect and verify weld integrity |

| Surface discoloration or slight corrosion | Damaged passivation layer or prolonged contact with high-concentration H₂O₂ | Re-electropolish and re-passivate the needle surface |

| Abnormal outlet direction | Needle tip impact or deformation of laser orifice | Slight deformation can be adjusted; replace the needle if severe |

| Flow fluctuation or air entrapment | Rapid pressurization, poor sealing, or pump pulsation | Inspect the inlet system and degassing structure |

Maintenance Schedule Recommendations

• Monthly: Inspect needle surface, threads, and seals.

• Quarterly: Test airtightness and flow stability.

• Semiannual: Full cleaning, passivation, and performance recheck.

• Annual: Replace needle assembly or upgrade to Inconel/Titanium models.

Tips to Extend Service Life

• Add pre-filters to prevent blockage.

• Increase system pressure gradually.

• Drain and dry before long-term storage.

• Avoid metal-to-metal collision during operation.

The H₂O₂ Transfer Needle is essential for safe, precise hydrogen peroxide delivery in medical, pharmaceutical, and industrial sterilization systems.

With precision machining, corrosion-resistant materials, and strict sealing control, it ensures long-term stability and operational safety.

Through proper installation, maintenance, and troubleshooting, the needle delivers consistent performance, enhancing sterilization efficiency, extending equipment lifespan, and reducing maintenance risk.

At Manners Medical, we continually refine our design and manufacturing processes to deliver safer, more durable, and more reliable H₂O₂ transfer solutions for global users.