Delve into dental implant fixtures, the cornerstone of smile restoration! Learn about their importance in creating a solid base for prosthetics and improving patient comfort.

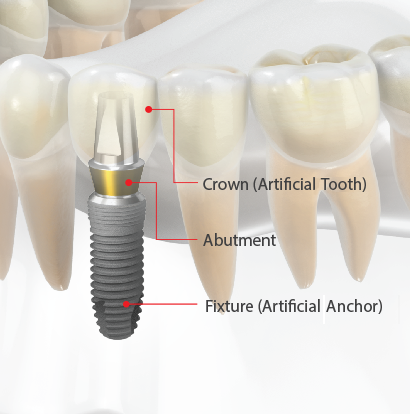

A dental implant is a specialized medical device used in modern dentistry to replace missing teeth, composed of multiple precision components that work together to ensure durability, stability, and aesthetics. Key components include the implant fixture, healing abutment, prosthesis and so on. The implant fixture, as the foundational element embedded within the jawbone, not only provides essential support but also determines the long-term durability and biocompatibility of the entire prosthetic solution. The high standards of Manners Technology in manufacturing ensure that it integrates seamlessly with the bone, delivering both functionality and comfort for the patient.

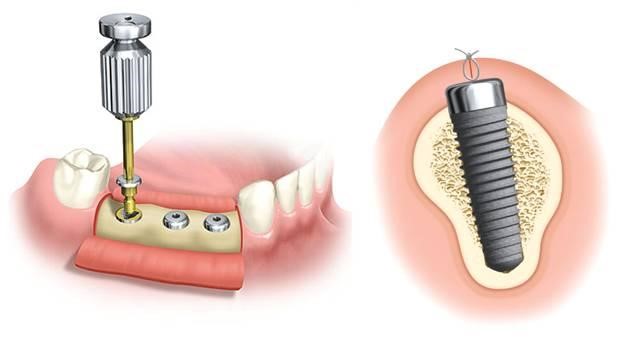

The dental implant fixture is a fundamental component in modern restorative dentistry, providing a stable foundation for replacing missing teeth. Designed to function as an artificial tooth root, the implant fixture is anchored into the jawbone, ultimately supporting prosthetics such as crowns, bridges, or dentures.

The implant fixtures can be classified by material: metal implants, such as pure titanium with treated surfaces to enhance osseointegration; ceramic implants, like zirconia, ideal for patients with metal sensitivities; and composite implants, which combine titanium and ceramic for durability and aesthetics.

They can also be classified by structure: one-piece implants with a simpler design for limited spaces; two-piece implants, offering flexibility and commonly used; and three-piece implants, allowing precise adjustment and often chosen for complex restorations.

The implant fixture's shape and threading play a critical role in its functionality. The body of the implant often has a cylindrical or conical shape with fine microthreads along its surface, which provide added surface area for bone contact. This threading is precisely engineered to distribute occlusal forces (those created by chewing and biting) in a manner that reduces stress on surrounding bone tissue, preventing bone loss and ensuring implant longevity.

Some advanced models also feature unique geometries, including tapered shapes that mimic natural tooth roots, or specialized threading that improves initial stability and distributes load evenly across the bone. These design elements facilitate ease of placement, while promoting the bone growth needed for effective integration. With expertise in precision customization, Manners Technology manufactures implants tailored to meet specific clinical needs, enhancing outcomes for both patients and practitioners.

The fabrication of dental implants requires meticulous attention to detail to ensure precision, durability, and biocompatibility. The process begins with material selection, typically titanium or titanium alloys, due to their proven success in osseointegration— the biological process through which the implant integrates with bone tissue. Titanium is particularly favored for its strength, corrosion resistance, and compatibility with bone cells, allowing for a stable foundation once the implant is in place.

In the production of implant fixtures, precision is of the utmost importance and the machining accuracy required is extremely high. At Manners Technology, we use advanced machines such as Siemens fully automatic CNC machines with five axes and an additional B-axis specifically designed for the precise, high-precision machining of the complex geometries necessary for implant fixture components. This ensures the highest precision when producing fine threads, tapers and surface features that are essential for successful implantation and integration with the bone.

The surface treatment of implant fixtures plays a crucial role in promoting the biological integration of the implant with the bone. Early implant fixtures featured smooth, mechanically polished surfaces, but modern implants typically employ roughened surfaces. This rough texture encourages the attachment of osteoblasts (bone-forming cells), which is vital for the process of osseointegration. To achieve this, several surface treatment techniques are used. The most common methods include titanium plasma spraying (as used by Nobel Biocare), large particle acid-etching (such as ITI's approach), anodization, and hydroxyapatite coating. In some cases, the implant is coated with additional bioactive materials that promote healing and increase integration speed.

Given the rigorous demands of dental implants, every fixture in Manners is subjected to extensive quality control, including stress testing and biocompatibility analysis. Our inspectors will simulate the forces and conditions the implant will endure once placed in the human jaw, ensuring that each fixture can withstand the repeated stresses of mastication without compromising structural integrity. Quality control measures also verify that each fixture’s dimensions and surface characteristics are consistent, maintaining reliability across batches.

At Manners Technology, we incorporate the latest technology and advanced methods to ensure the highest standards in both the precision machining and surface treatment of each implant fixture, ultimately enhancing osseointegration and long-term patient outcomes.