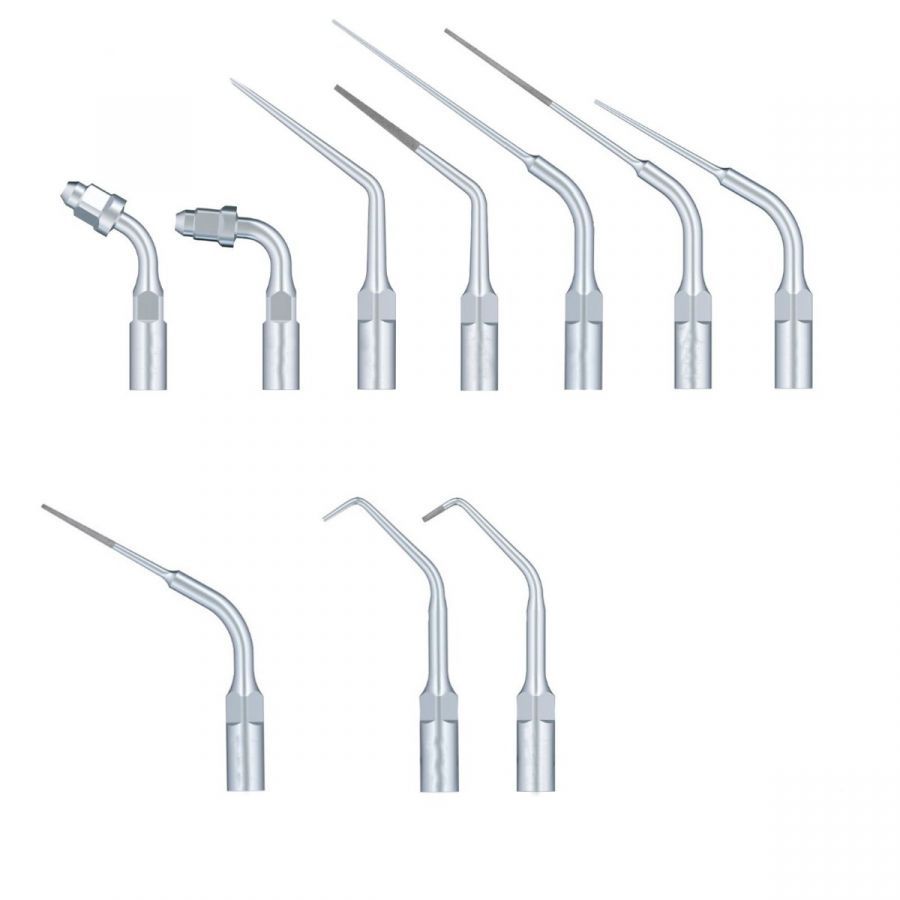

Discover high-quality dental scaler tips by Manners Technology for efficient plaque and tartar removal. Our precision-engineered tips offer durability, reducing replacement costs. Trust us for optimal oral care solutions.

Ultrasonic Scaler Tips, also known as “dental scaler tips” or “power scaling tips & inserts”, are specialized components used in ultrasonic scaler devices, primarily employed in dental practices for oral hygiene maintenance. These tips are designed to operate through ultrasonic vibrations, allowing for precise and effective removal of dental plaque, tartar, and stains from the surfaces of teeth. Made from high-quality materials and available in various sizes and shapes, these tips play a crucial role in maintaining oral hygiene. Ultrasonic scaler tips are a crucial part of dental cleaning procedures, as they provide a more efficient alternative to traditional manual scaling tools.

Ultrasonic scaler tips are extensively utilized in the field of dentistry, serving as essential tools for dental professionals across various procedures. These versatile tips excel in a range of applications, including the efficient removal of plaque and tartar from tooth surfaces. By harnessing ultrasonic vibrations, they effectively break down and eliminate these deposits.

Moreover, these tips are highly proficient in removing dental stains caused by smoking, coffee, or tea consumption, restoring the natural color of teeth with their gentle yet precise action. When dealing with more stubborn deposits like calculus, ultrasonic scaler tips prove to be highly effective, efficiently breaking down and removing hardened deposits from tooth surfaces. They also play a crucial role in root planning procedures, ensuring the thorough cleaning of tooth roots affected by periodontal disease, even in hard-to-reach areas that manual tools struggle to access.

In certain cases, these tips are employed for cavity preparation procedures, efficiently removing decayed tooth structure. Their versatility and precision make ultrasonic scaler tips indispensable instruments in modern dentistry, enhancing the effectiveness and comfort of various dental treatments.

The working tip of the scaler is a kind of key accessory of the ultrasonic scaler, which is installed at the end of the handle of the equipment, and is used in the dental scaling, periodontal treatment, cavity preparation, etc. The scaler tips are designed into different shapes and structures in accordance with the specific functions to be accomplished. Existing scaler tips are one-piece structures, i.e., the scaler tip is an integrated component from the tip connection part to the tip head. When the scaler tip is used, the head of the scaler tip is in contact with the tooth to perform operations such as scraping, grinding, drilling, and root canal scaling.

Ultrasonic scaler tips in Manners Technology are made from high-quality materials such as stainless steel, titanium, or medical-grade alloys like nickel titanium, etc. These materials ensure durability and resistance to corrosion, allowing for long-term use in clinical settings.

The scaler tips come in various shapes and sizes to accommodate different dental needs. They are typically classified based on their design and intended use in terms of their shapes, sizes, and functionality. Here are some common classification methods:

From shape: Ultrasonic scaler tips come in various shapes, and their classification is often based on their design. There are three common shapes. Round tips, for example, are usually used for general plaque and tartar removal, thanks to their circular design that helps evenly clean the tooth surfaces. Tapered tips, on the other hand, are suitable for more delicate tasks, such as endodontic treatments, as their pointed tips make it easier to access narrow areas. Additionally, flat tips are typically used for removing larger deposits of tartar, given their flat design that makes them suitable for effective scraping tasks.

From size: Tip sizes are usually represented by numbers, such as 1, 2, 3, and so on. The larger the number, the larger the tip size. Smaller tips are often used for precise work, while larger tips are suitable for cleaning larger areas of tooth surfaces.

From function: Ultrasonic scaler tips also have different functions based on their designs and purposes. Here are some common functional classifications. Universal scaling tips, for instance, are suitable for various general dental cleaning tasks, such as Model Universal Tip, Straight Tip S2, Flat Tip and other universal tip models. Periodontal tips, on the other hand, are specifically designed for treating periodontal treatment, such as cleaning and gum maintenance. Specific models can be exemplified as follows: Root Planing Tip R/L, Curette Tip P series, Perio Tip P4, Furcation Tip P20L and so on.

And its continuation version - Periodontal Tips (continuation) is more suitable for complex treatments, such as apical surgery, requiring deeper access to periodontal tissues. Endodontic tips or retro endodontic tips find their purpose in root canal treatment and apical surgery, such as Model Root Canal Tip E1, Endo Tip E3/E4/E5 and retro endodontic tips like Retro Tip R1/R2/R3R/R3L, and other Retro File RF series. Scaling tips are intended for removing tartar and plaque, while restorative tips are used for tasks during tooth restoration procedures, such as removing enamel and old fillings. Implant maintenance tips are designed for cleaning and maintaining tissues around dental implants, while crown and bridge tips are used for tasks during crown and bridge restorations. Finally, orthodontic tips are employed for cleaning and maintaining orthodontic appliances.

These tips can be classified not only based on their designs and purposes but also by the brand of the manufacturer, as each dental equipment manufacturer may have its unique tip designs. Each manufacturer’s matching instrument may have different models, and each model may require specific tips, which can be classified by models. Besides, ultrasonic scaler tips often come with different types of connection interfaces, such as threaded interfaces or insert-type interfaces. The type of interface also affects the compatibility of the tips, so the tips may be categorized based on the interface type.

In conclusion, the selection of tip size and shape depends on the specific procedure and the patient’s oral health requirements. Manners Technology offers a wide range of tip shapes and sizes to cater to diverse dental applications, providing cost-effective solutions without compromising on quality.

Manufacturing ultrasonic scaler tips involves a systematic process to ensure their quality and functionality. It starts with the selection of high-quality materials. Typically, these dental scaler tips are made from medical-grade stainless steel or other biocompatible alloys. The choice of material is essential to ensure durability, corrosion resistance, and compatibility with sterilization methods.

Then, precision machining is a crucial step in manufacturing dental scaler tips. Swiss Made 7 axis longitudinal lathes are used to shape and refine the tips according to the approved design. The lathe ensures the tips’ dimensions, holes, and all the features. Shapes are precise, allowing for optimal performance during dental procedures. Moreover, ultrasonic scaler tips require a smooth and polished surface to minimize friction and facilitate easy insertion into the oral cavity. Surface finishing techniques like polishing and electropolishing are employed to achieve the desired surface quality.

Throughout the manufacturing process, stringent quality control measures are enforced. These encompass dimensional inspections, material analysis, and comprehensive visual inspections to promptly identify defects or imperfections, with non-compliant tips being rejected. In summary, the manufacturing of ultrasonic scaler tips involves a combination of precision engineering, material science, quality control, and adherence to regulatory standards. These steps ensure that the tips are safe, effective, and reliable tools for dental professionals in maintaining oral health.

Besides, the existing dental scaler tips have an integral structure, meaning that the dental scaler tip is a unified component from its connection part to its tip end. During use, the dental scaler tip makes contact with the teeth using its tip end, performing tasks such as scraping, grinding, drilling, and root canal irrigation. The tip end of the dental scaler tip is prone to damage and wear. Once the tip end is damaged or worn, the entire dental scaler tip must be replaced, which can be costly. Manners Technology is dedicated to providing top-quality scaler tips, and our commitment to precision engineering and quality control ensures that our scaler tips provide optimal performance and durability, reducing the need for frequent replacements. All of this excellence makes us a trusted partner for dental professionals in dental instrument manufacturing and oral care.